Preparation method of sludge carbon-based material and sludge carbon-based material

A base material, sludge charcoal technology, applied in water/sludge/sewage treatment, chemical instruments and methods, water pollutants, etc. The effect of utilizing, increasing the utilization rate of waste, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention proposes a kind of preparation method of sludge carbon base material, comprises the following steps:

[0029] 1) mixing the sludge with the heavy metal wastewater, wherein the heavy metal salt content in the heavy metal wastewater is 100-1200 mg / L, stirring for a period of time to form a sludge mixture;

[0030] 2) filtering the sludge mixture, so that the sludge in the sludge aqueous solution is separated to obtain dehydrated sludge;

[0031] 3) Drying the dehydrated sludge: put the dehydrated sludge into a drying device, and heat and dry at 105° C. to obtain dried sludge;

[0032] 4) Carry out high-temperature carbonization treatment on the dried sludge, and grind and sieve the high-temperature carbonized product to form a powdery sludge carbon-based material.

[0033] Wherein, the heavy metal wastewater in step 1) is laboratory simulated wastewater containing heavy metal salts, wherein the heavy metal salts are copper nitrate, nickel nitrate, c...

example 1

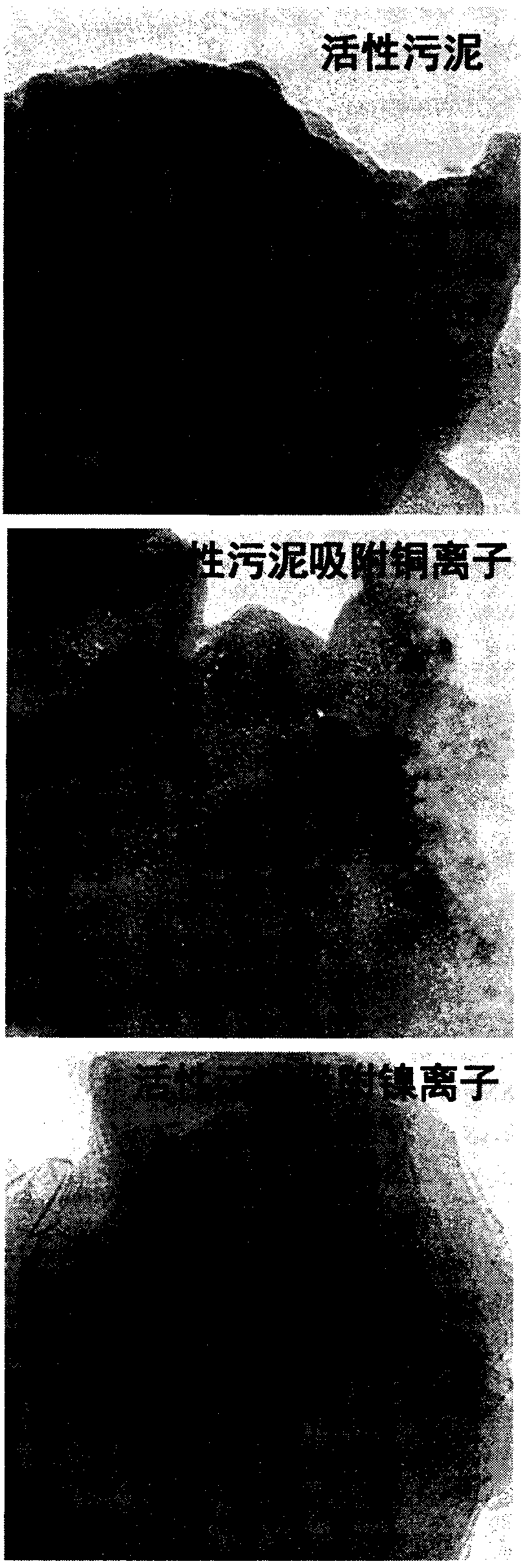

[0041]The laboratory simulated the preparation of heavy metal wastewater containing copper ions or nickel ions. Under the conditions of 200rpm / min and 180min, it was stirred and mixed with the sludge and then filtered, and the content of copper ions or nickel ions in the sludge system before and after the reaction was measured by inductively coupled plasma mass spectrometry. The results showed that the content of copper ions or nickel ions in the system after the heavy metal wastewater was mixed with sludge was 800 mg / L, and the content of copper ions and nickel ions in the filtrate decreased to 6.660 mg / L and 4.326 mg / L respectively after the reaction, and the removal efficiency 99.168% and 99.495% respectively, the heavy metal ions copper ions and nickel ions added in the system have been effectively adsorbed by the sludge. Such as figure 1 As shown in the transmission electron microscope image after the activated sludge adsorbs copper ions or nickel ions, the morphology of...

example 2

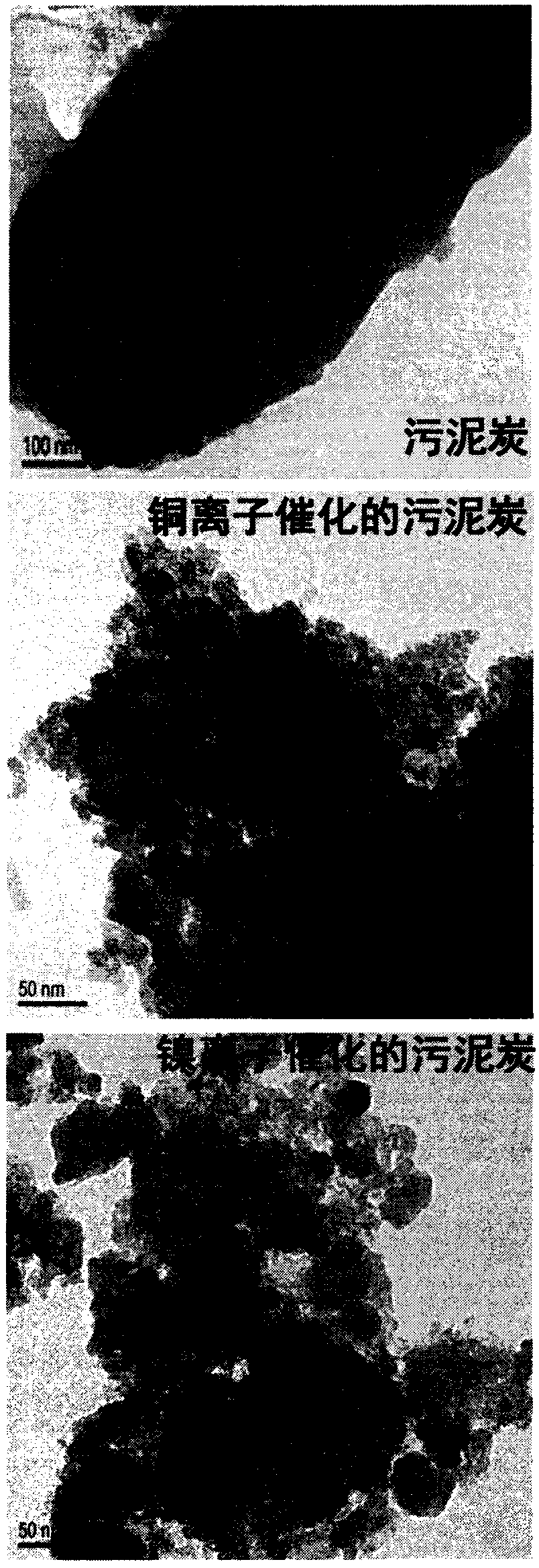

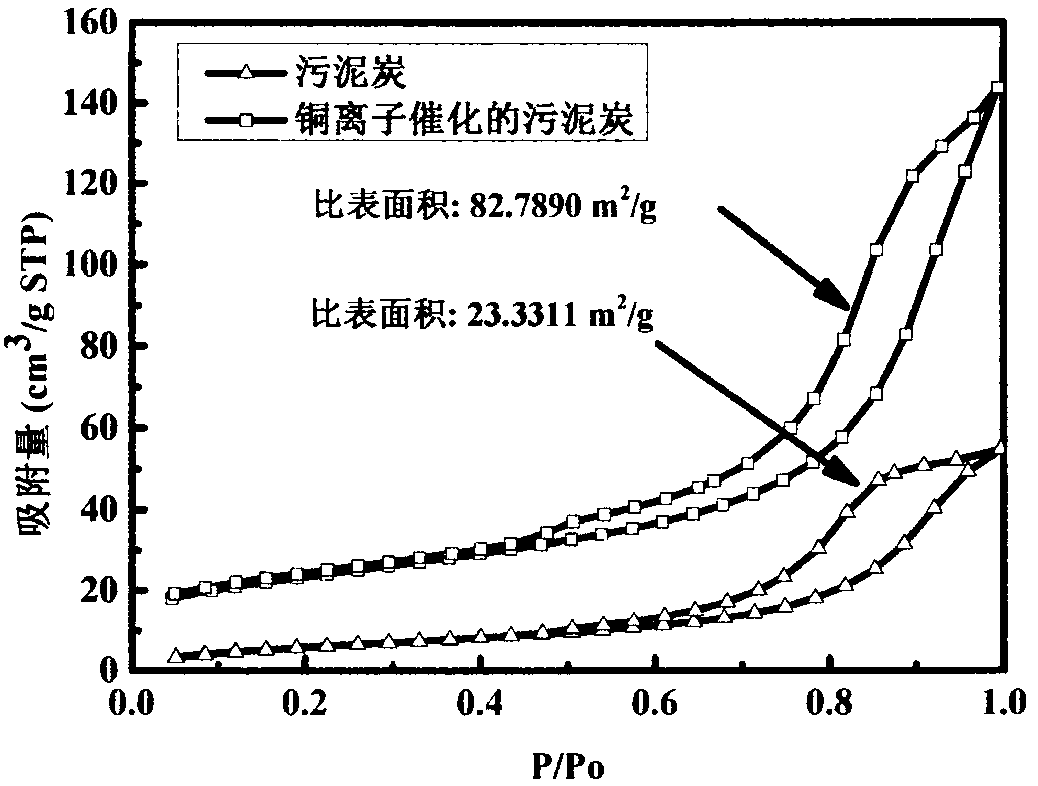

[0043] The laboratory simulates the preparation of copper ion or nickel ion heavy metal wastewater. The wastewater and sludge are mixed and stirred for a period of time and then filtered to separate the mud and water in the sludge aqueous solution; the dehydrated sludge is dried to obtain a dry Sludge: subject the dried sludge to high-temperature carbonization treatment, and grind and sieve the high-temperature carbonized product to obtain a powdery sludge carbon-based material; the specific operation is the same as the foregoing. The appearance of the transmission electron microscope of the sludge carbon-based material prepared by copper ion and nickel ion catalysis is as follows: figure 2 As shown, the carbonized heavy metal activated sludge forms porous carbon-based metal functional materials. Determine its specific surface area as image 3 with Figure 4 , the specific surface area of the sludge carbon-based material prepared by using copper ions and nickel ions to ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com