A method for comprehensive utilization of boron mud

A boron mud and filtrate technology, applied in the directions of boron compounds, boron oxide compounds, chemical instruments and methods, etc., can solve the problems of inability to recover boron mud and magnesium, pollution of boron mud, failure to eliminate boron mud, etc., to reduce energy consumption, The effect of saving energy and realizing environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

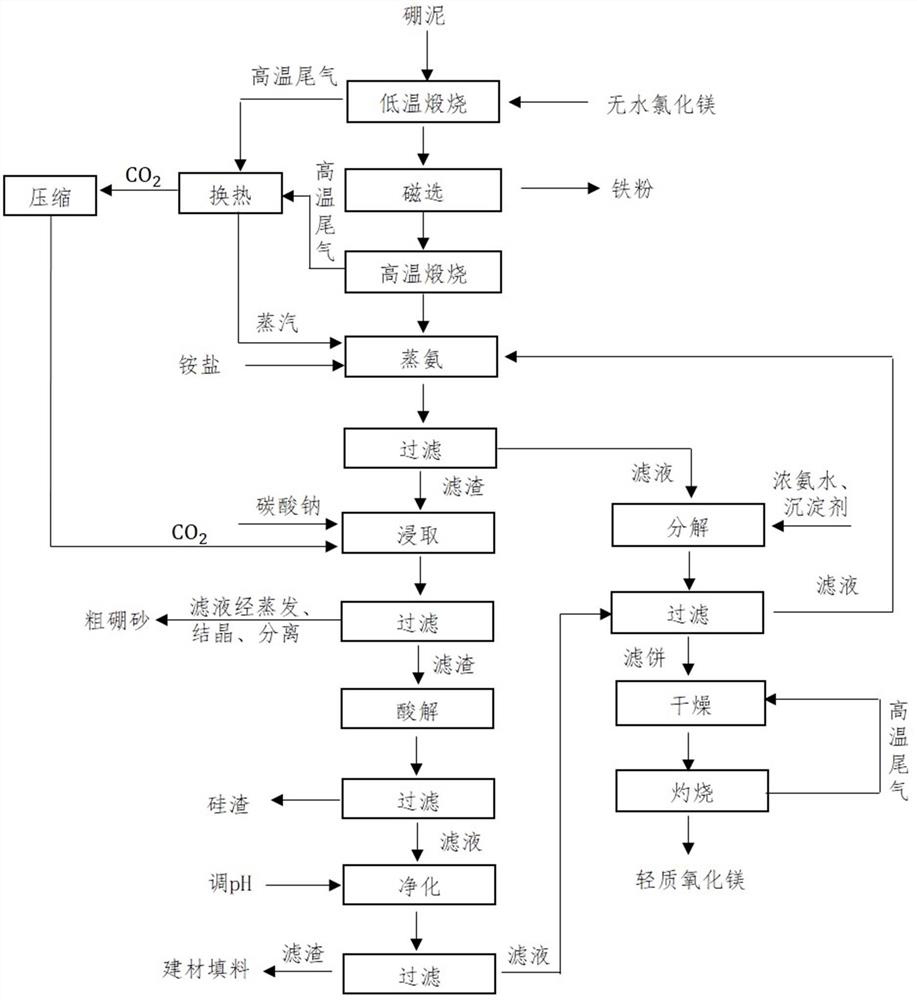

Image

Examples

Embodiment 1

[0045] A method for comprehensive utilization of boron mud in the present embodiment comprises the following steps:

[0046] (1) Grinding the boron mud so that the proportion of 120-200 mesh boron mud is more than 95%, and the pretreated boron mud is obtained;

[0047] (2) Fully mix the pretreated boron mud and anhydrous magnesium chloride in step (1) according to the mass ratio of 1:1.6, place them in a suspension calciner for low-temperature calcining, the low-temperature calcining temperature is 550°C, and the calcining time is 30 minutes to obtain low-temperature calcining Boron mud;

[0048] (3) Perform magnetic separation on the boron slime calcined at low temperature in step (2), the magnetic field strength is 350 mT, the iron recovery rate is between 75%, and the boron slime after iron removal is obtained;

[0049] (4) The boron slime after iron removal in step (3) is subjected to high-temperature calcination in a suspension calcination furnace. The high-temperature c...

Embodiment 2

[0061] A method for comprehensive utilization of boron mud in the present embodiment comprises the following steps:

[0062] (1) Grinding the boron mud so that the proportion of 120-200 mesh boron mud is more than 95%, and the pretreated boron mud is obtained;

[0063] (2) Fully mix the pretreated boron mud and anhydrous magnesium chloride in step (1) according to the mass ratio of 1:1.7, place them in a suspension calciner for low-temperature calcining, the low-temperature calcining temperature is 650°C, and the calcining time is 20 minutes to obtain low-temperature calcining Boron mud;

[0064] (3) Perform magnetic separation on the boron slime calcined at low temperature in step (2), the magnetic field strength is 400mT, the iron recovery rate is between 80%, and the boron slime after iron removal is obtained;

[0065] (4) The boron slime after iron removal in step (3) is subjected to high-temperature calcination in a suspension calcination furnace. The high-temperature ca...

Embodiment 3

[0077] A method for comprehensive utilization of boron mud in the present embodiment comprises the following steps:

[0078] (1) Grinding the boron mud so that the proportion of 120-200 mesh boron mud is more than 95%, and the pretreated boron mud is obtained;

[0079] (2) Fully mix the pretreated boron mud and anhydrous magnesium chloride in step (1) according to the mass ratio of 1:1.8, place them in a suspension calciner for low-temperature calcining, the low-temperature calcining temperature is 700°C, and the calcining time is 10 minutes to obtain low-temperature calcining Boron mud;

[0080] (3) Perform magnetic separation on the boron slime calcined at low temperature in step (2), the magnetic field strength is 500mT, the iron recovery rate is between 85%, and the boron slime after iron removal is obtained;

[0081] (4) The boron slime after iron removal in step (3) is subjected to high-temperature calcination in a suspension calcination furnace. The high-temperature ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com