Preparation method of aluminum calcium carbonate composite cementing material and product thereof

A composite cementing material and carbonate technology, which is applied in the field of preparation of aluminum-calcium carbonate composite cementing material, to achieve the effect of reducing heavy metal precipitation and alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) After ball milling, the Bayer process red mud with an average particle size of 60 microns and limestone (calcium-silica blending mineral) are mixed in a mass ratio of 1:0.14 (the molar ratio of calcium to silicon in the mixture is 1.26-1.28:1) The mixture is calcined at a high temperature of 800 degrees Celsius for 4 hours, cooled, washed with water, and dried as thermally activated red mud.

[0051] (2) The thermally activated red mud has a magnetic field strength of 160kA·m -1 Under the conditions of magnetic separation, the iron recovery rate is 78.1%, and the remaining sodium oxide content (alkali content) is 0.41%.

[0052] (3) The thermally activated red mud, cement (PO42.5) and fly ash (average particle size less than 15 microns) after magnetic separation are uniformly dry mixed according to 70:20:10, and 40% of the total solid mass is added to the water to fully mix. Injection molding, leave the mold naturally for 8 hours, continue to stand for 40 hours, control ...

Embodiment 2

[0054] (1) After ball milling, the Bayer process red mud with an average particle size of 20 microns is mixed with limestone in a mass ratio of 1:0.14 (the molar ratio of calcium to silicon in the mixture is 1.26-1.28:1), and the mixture is at 800 degrees Celsius Calcined at high temperature for 4 hours, cooled, washed with water, and dried as thermally activated red mud.

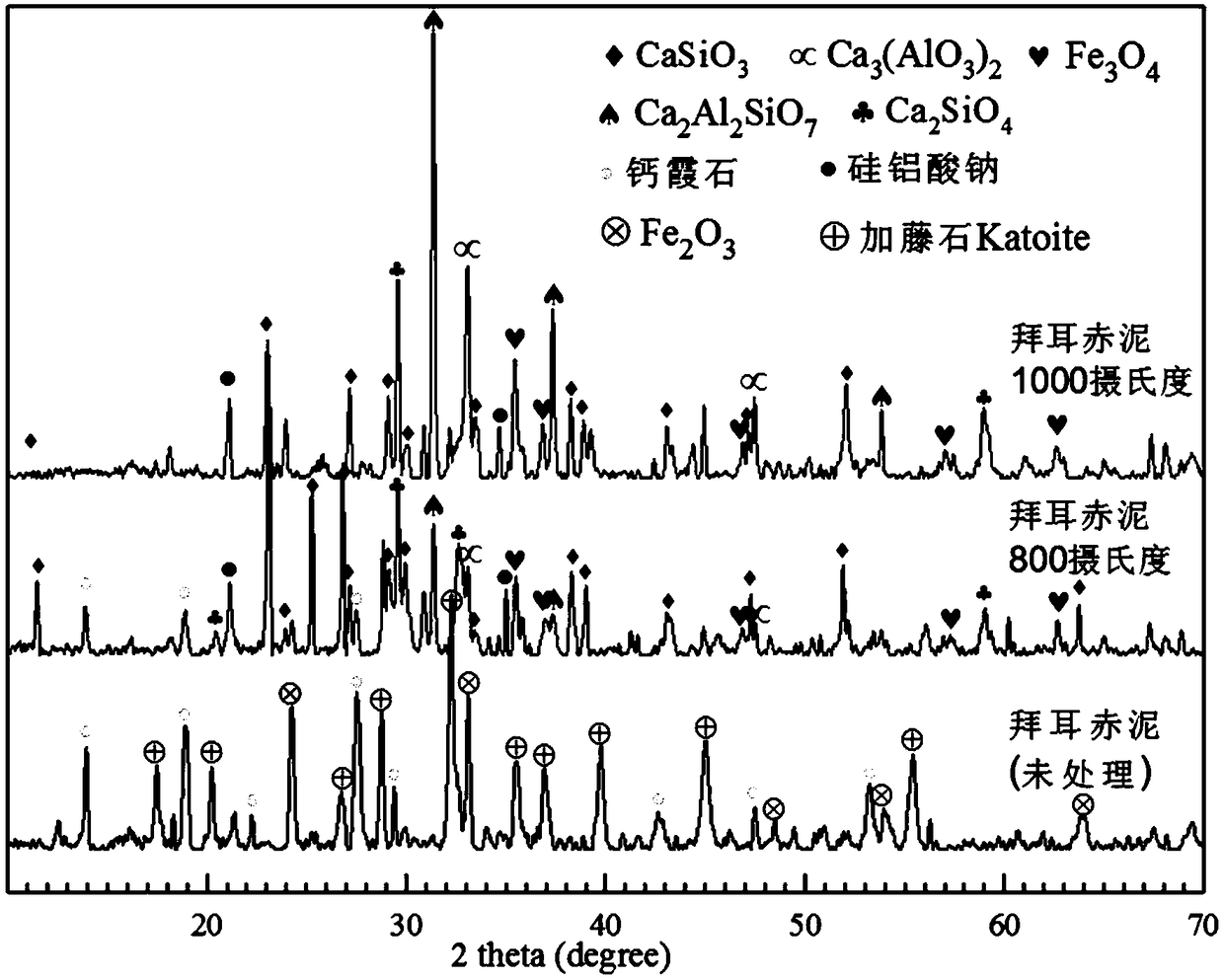

[0055] The raw material Bayer process red mud and the Bayer process red mud after being calcined at a high temperature at 800 degrees Celsius for 4 hours and cooled by XRD characterization, the ore phase map is as follows figure 1 As shown, the crystalline minerals of Cancrinite, Katoite (garnet) and iron oxide in the raw materials of Bayer process red mud are thermally activated at 800 degrees Celsius with a suitable calcium-silica molar ratio. Except for a small amount of cancrinite, remains. Among other minerals, the calcium and silicon components are mainly converted into calcium silicate (CaSiO 3 ) And a ...

Embodiment 3

[0059] (1) Mixed red mud with an average particle size of 20 microns after ball milling (Bayer process red mud and sintering process red mud are 60% and 40% respectively) and limestone are mixed in a mass ratio of 1:0.08 (calcium in the mixture and The molar ratio of silicon is 1.34-1.36:1), the mixture is calcined at a high temperature of 800 degrees Celsius for 4 hours, cooled, washed with water, and dried as thermally activated red mud.

[0060] (2) The thermally activated red mud has a magnetic field strength of 160kA·m -1 Under the conditions of magnetic separation, the iron recovery rate is 79.7%, and the remaining sodium oxide content is 0.27%.

[0061] (3) The thermally activated red mud, cement (PO42.5) and fly ash (average particle size less than 15 microns) after magnetic separation are uniformly dry mixed according to 70:25:5, and 40% of the total solid mass is added to the water to fully mix. Injection molding, leave the mold naturally for 8 hours, continue to stand fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com