A kind of preparation method of water-based polyaniline modified epoxy cationic emulsion

A water-based polyaniline, ionic emulsion technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of unimproved compatibility, affecting the comprehensive anti-corrosion performance of water-based epoxy coatings, aggregation and delamination, etc. , to achieve the effect of improving long-term anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

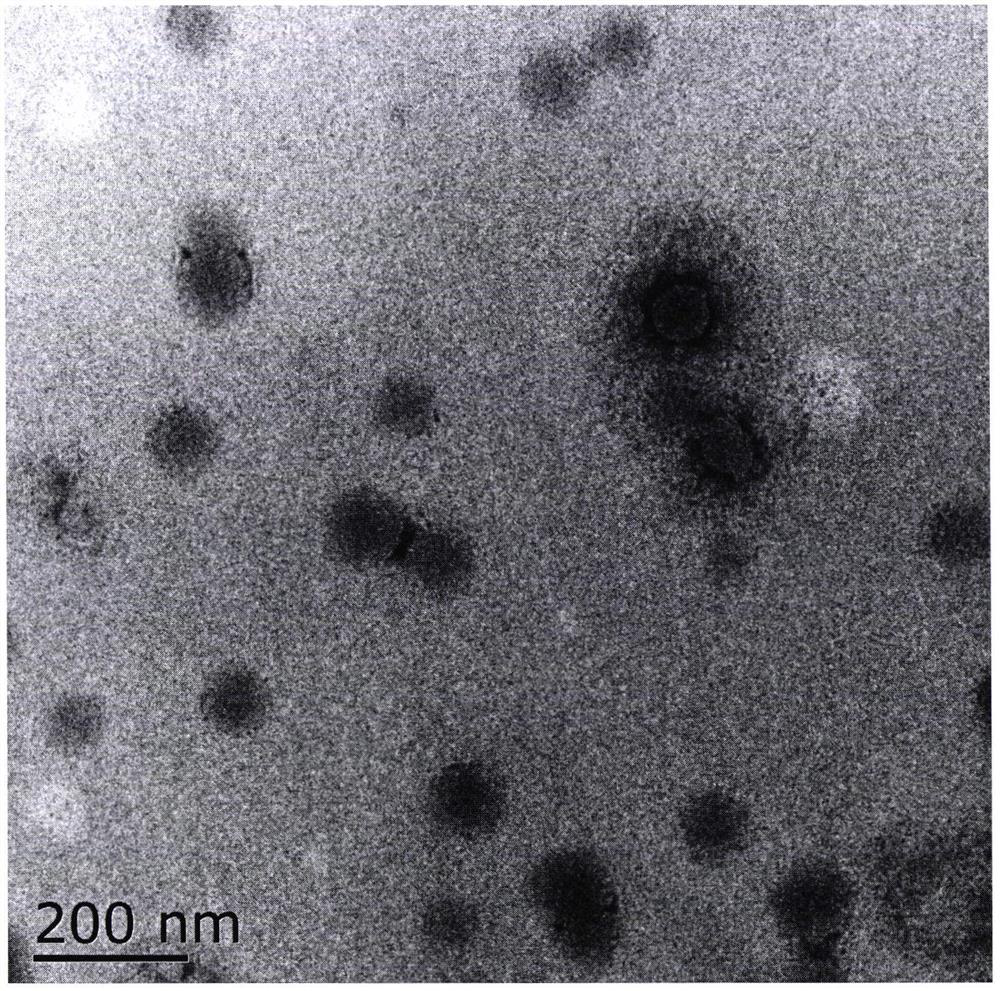

Image

Examples

Embodiment 1

[0027] The preparation of water-based polyaniline modified epoxy cationic emulsion, the specific formula is shown in Table 1:

[0028] The preparation formula of table 1 waterborne polyaniline modified epoxy cationic emulsion

[0029] Epoxy resin (equivalent weight 196) 25g Alcohol solvent n-butanol 10g Diethanolamine 7g 5-aminosalicylic acid 0.03g Acetic acid 5.5g aniline 0.5g Ditoluoyl peroxide 1g Deionized water 50.97g

[0030] According to Table 1, heat up the epoxy resin and solvent to 60°C with stirring, and preheat for 15 minutes; raise the temperature to 85°C, add diethanolamine dropwise evenly, and add the dropwise time for 15 minutes; cool down to 60°C, add 5-amino water Salicylic acid, react for 15 minutes, add acetic acid, react for 30 minutes; heat up to 65°C, add aniline, add dibenzoyl peroxide solution under stirring conditions, and then react at constant temperature for 4 hours; to 50°C, remove the solven...

Embodiment 2

[0033] The preparation of water-based polyaniline modified epoxy cationic emulsion, the specific formula is shown in Table 2:

[0034] The preparation formula of table 2 waterborne polyaniline modified epoxy cationic emulsion

[0035] Epoxy resin (equivalent weight 400) 25g Xylene 20g Diethanolamine 3.1625g 5-aminosalicylic acid 0.0875g Acetic acid 3g aniline 1.75g Ditoluoyl peroxide 5g Deionized water 42g

[0036] According to Table 2, heat the epoxy resin and solvent to 60°C with stirring, preheat for 15 minutes; heat up to 85°C, add diethanolamine dropwise for 15 minutes; cool down to 60°C, add 5-amino water Salicylic acid, react for 15 minutes, add acetic acid, react for 30 minutes; heat up to 67°C, add aniline, add dibenzoyl peroxide solution under stirring conditions, and then react at constant temperature for 4 hours; to 50°C, remove the solvent under reduced pressure, and then Add deionized water for high-speed ...

Embodiment 3

[0038] The preparation of water-based polyaniline modified epoxy cationic emulsion, the specific formula is shown in Table 3:

[0039] The preparation formula of table 3 waterborne polyaniline modified epoxy cationic emulsion

[0040] Epoxy resin (equivalent to 500) 35g Alcohol ether solvent propylene glycol methyl ether 16.9g Diethylamine 4.5g p-aminobenzoic acid 0.00625g Acetic acid 3g aniline 0.125g Azobisisobutylcyanide 0.5g Deionized water 40g

[0041] According to Table 3, heat up the epoxy resin and solvent to 60°C with stirring, and preheat for 30 minutes; raise the temperature to 75°C, add diethanolamine dropwise for 30 minutes; cool down to 50°C, add 5-amino salicyl Acid, react for 30 minutes, add acetic acid, react for 25 minutes; heat up to 75°C, add aniline, add azobisisobutylcyanide solution under stirring conditions, and then react at constant temperature for 24h; to 50°C, remove the solvent under reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com