Reinforced and toughened nylon 6 resin, nylon alloy and preparation method

A resin, in-situ polymerization technology, used in the preparation of reinforced and toughened nylon 6 resin, nylon alloy resin, nylon alloy and preparation fields, can solve the problems of the decline of the total crystallization rate of composite materials, obstacles, etc., to improve toughness, tensile strength, etc. Effects of reduced strength and flexural strength, and reduced phase separation of rubber components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

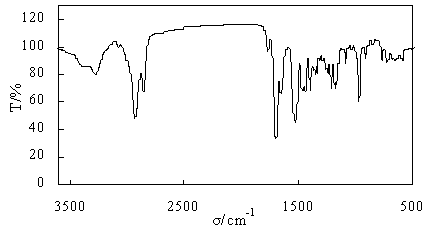

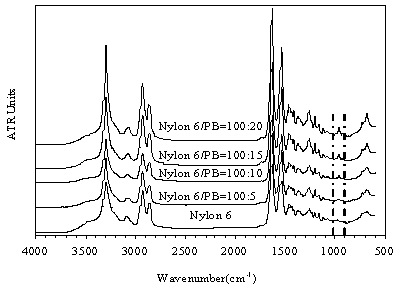

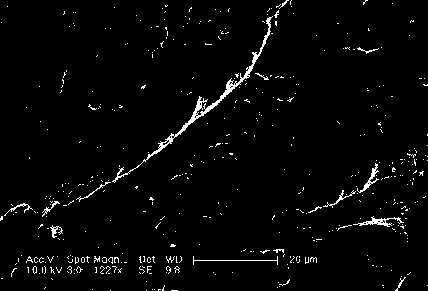

Image

Examples

Embodiment 1

[0026] 1) Hydroxyl-terminated liquid polybutadiene HTPB treatment

[0027] Add 35g of hydroxyl-terminated liquid rubber (hydroxyl-terminated liquid polybutadiene HTPB, number average molecular weight is 2300) into 50g of dry dehydrated xylene solvent, add 50g of HDI uretdione, and react at 80℃~110℃ for 3h under the protection of nitrogen , then raise the temperature to 130°C for 2 hours, add 35g of vacuum-dehydrated caprolactam to react for 3 hours, control the reaction temperature at 120°C to 140°C, then lower it to room temperature, add excess isopropanol solvent, and let it stand overnight to precipitate the caprolactam-capped rubber activator , after several times of isopropanol solvent purification, vacuuming to remove small molecular substances, to obtain HDI uretdione grafted and caprolactam-capped hydroxyl-terminated liquid rubber.

[0028] 2) Surface modification of hydroxylated carbon nanotubes

[0029] The length of the hydroxylated carbon nanotubes used is 10-30um...

Embodiment 2

[0036] 1) Hydroxyl-terminated liquid nitrile rubber HTBN treatment

[0037] Adopt hydroxyl-terminated liquid nitrile rubber HTBN, wherein the number-average molecular weight of hydroxyl-terminated liquid nitrile rubber HTBN is 4500, 68g hydroxyl-terminated liquid nitrile rubber HTBN is added in the dry dehydrated 100g xylene solvent, add 50gHDI uretdione, Under the protection of nitrogen, react at 110°C for 3 hours, then raise the temperature to 130°C for 2 hours, add 35g of vacuum dehydrated caprolactam to react for 3 hours, control the reaction temperature at 120°C to 140°C, the reaction temperature can be 120°C, or 130°C, 140°C, then Cool down to room temperature, add excess isopropanol solvent, and let it stand overnight to precipitate caprolactam-capped rubber activator. After several times of isopropanol solvent purification, vacuumize to remove small molecular substances, and obtain HDI uretdione for grafting. Caprolactam-terminated hydroxyl-terminated liquid rubber.

...

example 2

[0040] Example 2, the mechanical properties of the modified nylon sample are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com