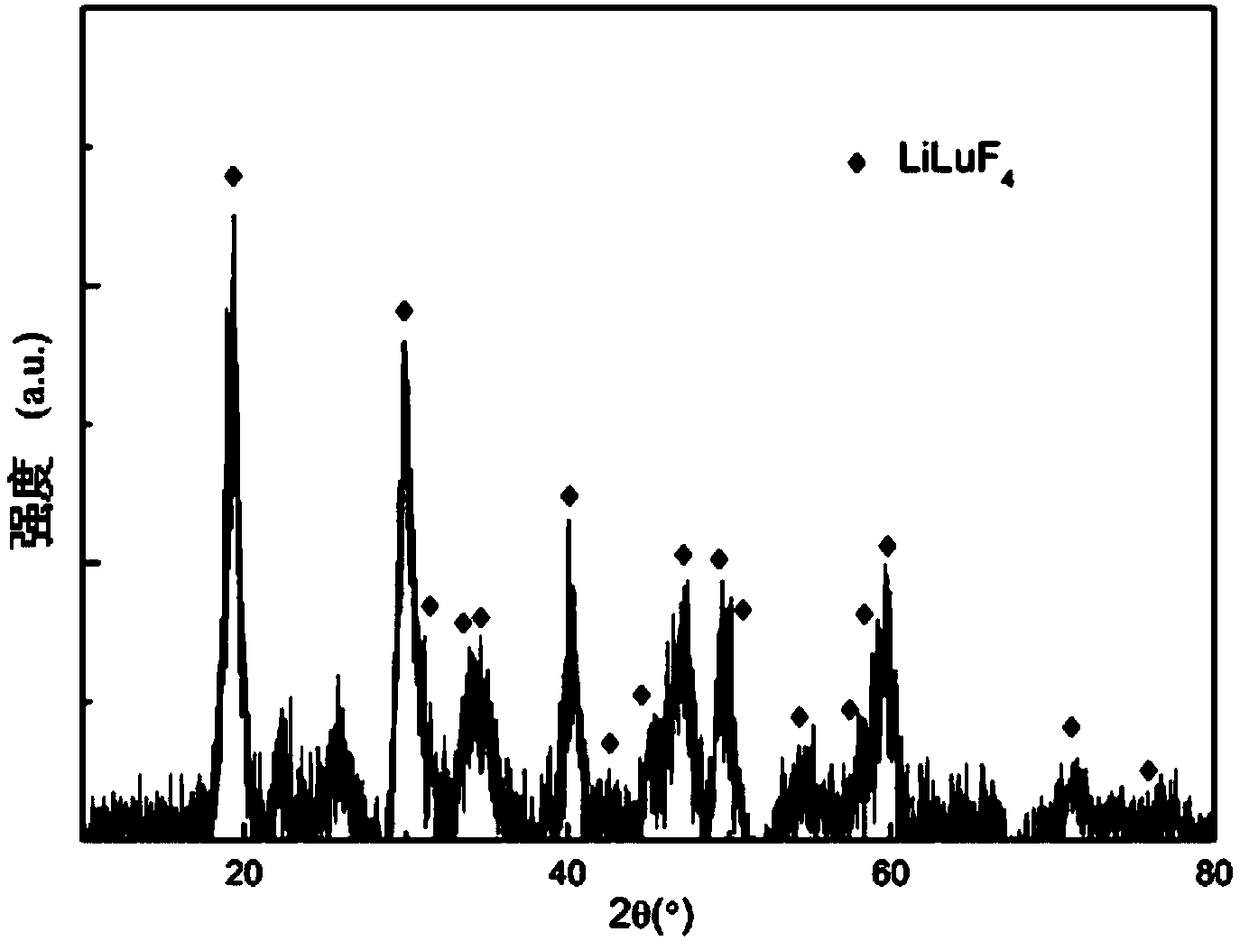

Neodymium-doped lutetium lithium fluoride nanomaterial as well as preparation method and application thereof

A technology of neodymium lutetium fluoride lithium and nanomaterials, which is applied in the field of nanomaterial preparation, can solve the problems of irregular size, large consumption of raw materials, and unfavorable promotion, etc., and achieve large-scale industrial production and easy large-scale industrial production , the effect of solving the solubility problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Follow LiLu m Nd n f 4 The molar ratio of each atom in the chemical formula weighs the following materials in corresponding molar quantities: 1mmol lithium hydroxide, 0.99mmol lutetium stearate, 4mmol ammonium fluoride and 0.01mmol neodymium nitrate, wherein m=0.99; n=0.01. Add 50ml of methanol and 50ml of water in a beaker at a volume ratio of 1:1 as a solvent, then add 4mmol of ammonium fluoride and 0.01mmol of neodymium nitrate as a solute, and simultaneously heat, heat, and magnetically stir at 50°C to form fluorine Methanol and aqueous solution of ammonium fluoride and neodymium nitrate; then dissolve 1mmol lithium hydroxide in 10ml of deionized water, and then drop into the methanol and aqueous solution of ammonium fluoride and neodymium nitrate at a titration rate of 1ml / min, with constant stirring , the stirring time is 3h, and the separation system I is formed. According to the volume ratio of 1:3, add 10ml oleic acid and 30ml octadecene in the beaker as a s...

Embodiment 2

[0074] Follow LiLu m Nd n f 4 The molar ratio of each atom in the chemical formula weighs the following materials in corresponding molar quantities: 1mmol lithium hydroxide, 0.98mmol lutetium stearate, 4mmol ammonium fluoride and 0.02mmol neodymium nitrate, wherein m=0.98; n=0.02. Add 50ml of methanol and 50ml of water in a beaker at a volume ratio of 1:1 as a solvent, then add 4mmol of ammonium fluoride and 0.02mmol of neodymium nitrate as a solute, and simultaneously heat, heat, and magnetically stir at a temperature of 55°C to form fluorine Methanol and aqueous solution of ammonium fluoride and neodymium nitrate; then 1mmol lithium hydroxide was dissolved in 10ml deionized water, and then dropped into the methanol and aqueous solution of ammonium fluoride and neodymium nitrate at a titration rate of 1.5ml / min, accompanied by non-stop Stir for 2.5 hours to form a separation system I. According to the volume ratio of 1:3, add 10ml oleic acid and 30ml octadecene as a solven...

Embodiment 3

[0076] Follow LiLu m Nd n f 4The molar ratio of each atom in the chemical formula weighs the following materials in corresponding molar quantities: 1mmol lithium hydroxide, 0.97mmol lutetium stearate, 4mmol ammonium fluoride and 0.03mmol neodymium nitrate, wherein m=0.97; n=0.03. Add 50ml of methanol and 50ml of water in a beaker at a volume ratio of 1:1 as a solvent, then add 4mmol of ammonium fluoride and 0.03mmol of neodymium nitrate as a solute, and simultaneously heat, heat, and magnetically stir at 60°C to form fluorine Methanol and aqueous solution of ammonium fluoride and neodymium nitrate; then dissolve 1mmol lithium hydroxide in 10ml of deionized water, and then drop into the methanol and aqueous solution of ammonium fluoride and neodymium nitrate at a titration rate of 2ml / min, with continuous stirring , the stirring time is 2h, and the separation system I is formed. According to the volume ratio of 1:3, add 10ml oleic acid and 30ml octadecene as a solvent in a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com