Method for pickling waste sulfuric acid by comprehensive utilization of steel

A technology of iron and steel pickling waste and sulfuric acid, which is applied in the field of chemical resource recycling, can solve the problems of poor disposal effect, high treatment cost, complicated process, etc., and achieve the effect of improving utilization rate, no secondary pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

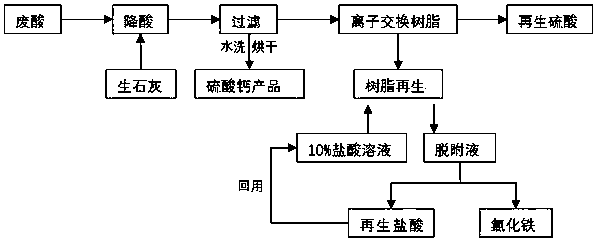

[0031] according to figure 1 Process flow chart:

[0032] (1) First, take 500mL of waste sulfuric acid, add 25.2g of quicklime, and stir for 5 minutes. At this time, the pH value is 1.32. Filter with suction to obtain the filter cake and yellow-brown filtrate. Rinse the filter cake with distilled water for 3 times, and dry it at 105°C. 2h, obtain calcium sulfate product, calcium sulfate content is 96.94%;

[0033] (2) Take 100mL of the yellow-brown filtrate in a 250mL beaker, put 30mL of cation exchange resin into it, and stir slowly at room temperature for 10min to obtain regenerated sulfuric acid, wherein the metal impurity content is 0.17%;

[0034] (3) Take out the resin saturated with adsorption, put it in a 250mL beaker, add 100mL of 10% hydrochloric acid solution, place it on a water bath constant temperature oscillator for desorption, shake at 25°C for 30min, and obtain the regenerated resin and desorption solution;

[0035] (4) Take the desorption solution and disti...

Embodiment 2

[0038] according to figure 1 Process flow chart:

[0039] (1) First, take 500mL of waste sulfuric acid, add 26.04g of quicklime, and stir for 7 minutes. At this time, the pH value is 1.57. Filter with suction to obtain the filter cake and yellow-brown filtrate. Rinse the filter cake with distilled water for 3 times, and dry it at 105°C. 3h, obtain calcium sulfate product, calcium sulfate content is 97.38%;

[0040] (2) Take 100mL of the yellow-brown filtrate in a 250mL beaker, put 28.57mL of cation exchange resin into it, and stir slowly at room temperature for 20min to obtain regenerated sulfuric acid, wherein the metal impurity content is 0.12%;

[0041] (3) Take out the adsorbed saturated resin, put it in a 250mL beaker, add 100mL of 10% hydrochloric acid solution, place it on a water bath constant temperature oscillator for desorption, shake at 25°C for 40min, and obtain the regenerated resin and desorption solution;

[0042] (4) Take the desorption solution and distill ...

Embodiment 3

[0044] according to figure 1 Process flow chart:

[0045] (1) First, take 500mL of waste sulfuric acid, add 26.46g of quicklime, and stir for 10 minutes. At this time, the pH value is 1.96. Filter cake and yellow-brown filtrate by suction filtration. Rinse the filter cake with distilled water for 3 times, and dry it at 105°C. 5h, obtain calcium sulfate product, calcium sulfate content is 97.38%;

[0046] (2) Take 100mL of the yellow-brown filtrate in a 250mL beaker, put 25mL of cation exchange resin into it, and stir slowly at room temperature for 20min to obtain regenerated sulfuric acid, wherein the metal impurity content is 0.08%;

[0047] (3) Take out the adsorbed saturated resin, put it in a 250mL beaker, add 100mL of 10% hydrochloric acid solution, place it on a water bath constant temperature oscillator for desorption, shake at 25°C for 40min, and obtain the regenerated resin and desorption solution;

[0048] (4) Take the desorption solution and distill and concentrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com