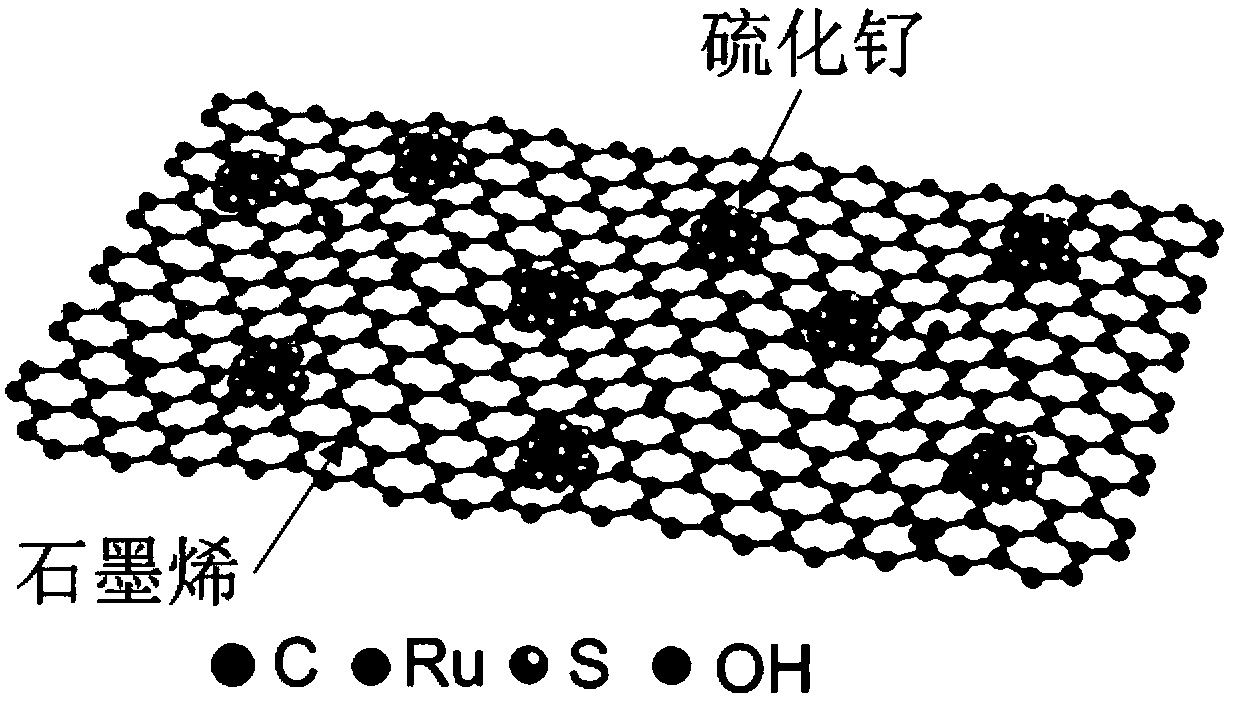

Ruthenium sulfide composite material and preparation method and applications thereof

A composite material, ruthenium sulfide technology, applied in electrolytic components, electrodes, electrolytic process, etc., can solve the problems that cannot meet the requirements of industrial applications, large-scale application limitations, catalytic performance attenuation, etc., and achieve unique and ingenious preparation methods and low prices , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare 40 milliliters of an aqueous solution containing 0.5 mmol / L of ruthenium chloride and 10 mmol / L of thioacetamide, add it to the reaction kettle, then add 20 mg of graphene powder into the reaction kettle, and stir evenly. Then the reaction kettle was sealed, the temperature was raised to 150° C. and kept under autogenous pressure for 6 hours to carry out the solvothermal reaction. After the reaction is finished, it is naturally cooled, centrifuged, washed and dried to obtain a graphene-based ruthenium sulfide particle composite material.

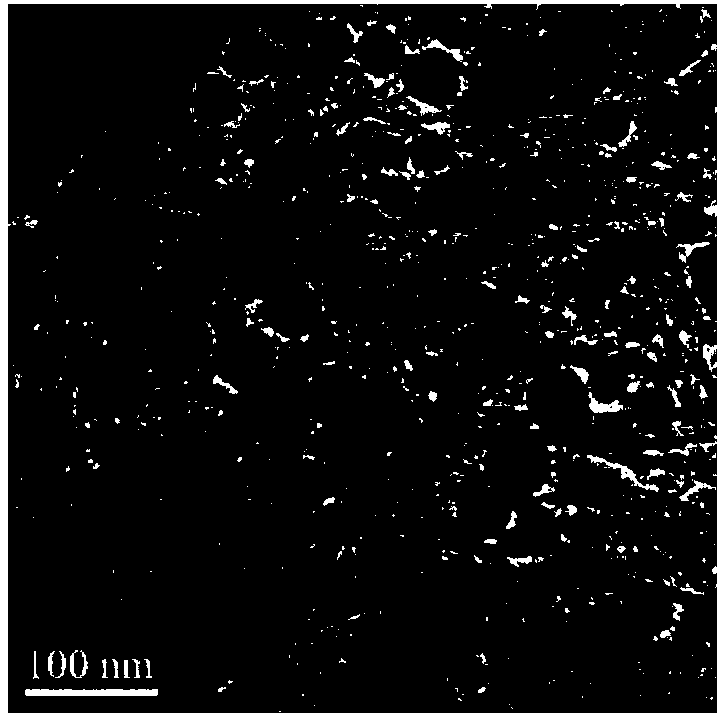

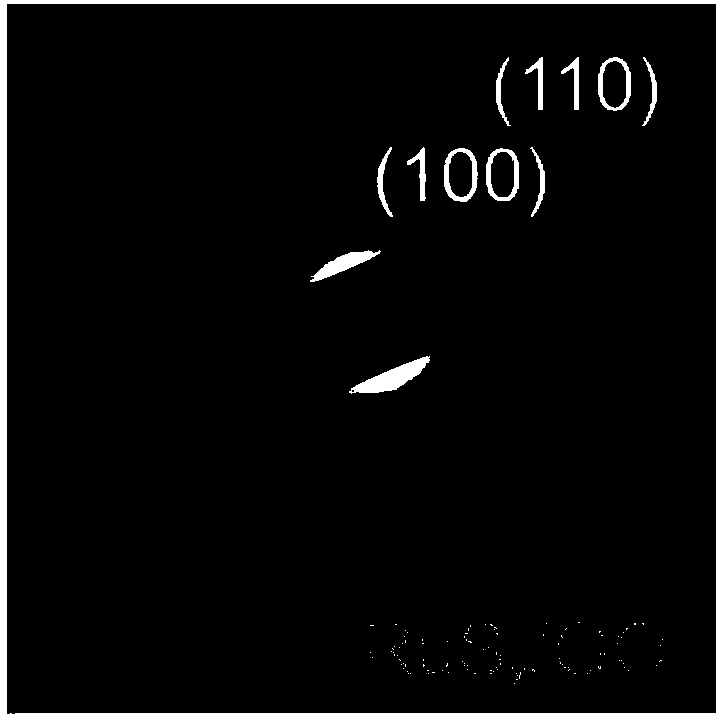

[0037] The obtained ruthenium sulfide particle composite material transmission electron microscope picture sees attached figure 2 , and its electron diffraction pattern is shown in the appendix image 3 , and its elemental distribution diagram is shown in the appendix Figure 4 , and its XRD spectrum is shown in the attached Figure 5 . From figure 2 It can be seen that the ruthenium sulfide particles are evenly distrib...

Embodiment 2

[0039] Referring to the method in Example 1, the thioacetamide was replaced with thiourea, and the solvothermal reaction conditions were changed to: the temperature was 150° C., and the reaction time was 6 hours.

[0040] The transmission electron microscope photo of the obtained ruthenium sulfide particle composite material is referring to the attached Figure 6 .

Embodiment 3

[0042] Referring to the method in Example 1, the water was replaced with ethanol, and the solvothermal reaction conditions were changed to: the temperature was 150° C., and the reaction time was 6 hours.

[0043] The transmission electron microscope photo of the obtained ruthenium sulfide particle composite material is referring to the attached Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com