Preparation method for China-hemp antibacterial fiber material

An antibacterial fiber and hemp technology, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of difficulty in meeting human antibacterial needs, the reduction of antibacterial properties of hemp fiber, and the loss of antibacterial components, and achieve excellent antibacterial properties. Long-lasting antibacterial effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention discloses a preparation method of hemp antibacterial fiber material, which comprises the following steps:

[0031] (1) reacting hemp fibrils with alkali to obtain alkalized hemp fibers;

[0032] (2) oxidizing the alkalized hemp fiber with an oxidizing agent to obtain oxidized hemp fiber;

[0033] (3) reacting the oxidized hemp fiber with triethylenetetramine to obtain aminated hemp fiber;

[0034] (4) reacting the aminated hemp fiber with glycidyltrimethylammonium halide to obtain a hemp antibacterial fiber material containing a quaternary ammonium antibacterial functional group.

[0035] The preparation method of the hemp antibacterial fiber material described in the embodiment of the present invention is simple in process, easy to operate, easy to control, and friendly to the environment.

[0036] The embodiment of the present invention uses commercial-grade hemp fibrils as the basic raw material; specifically, the count of the hemp fibrils can be 1500...

Embodiment 1

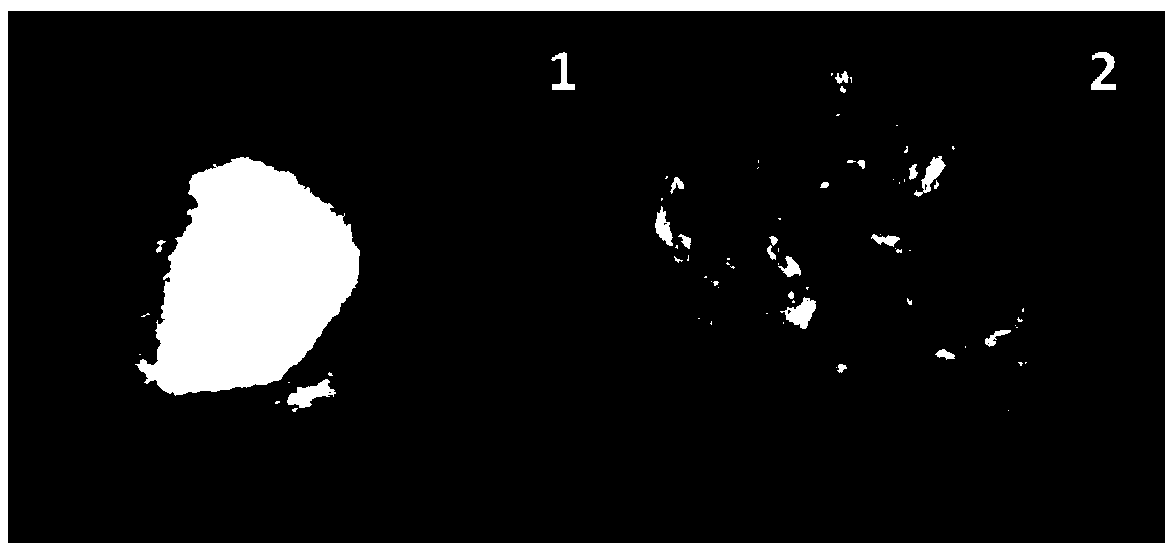

[0058] (1) Prepare 160mL of 18% sodium hydroxide solution, then add 2.0g hemp fibrils (for the actual situation, see figure 1 middle left part), fully swell the fibers, soak and react at 20°C for 60 minutes, take out the fibers, wash with distilled water several times, and dry in a constant temperature drying oven at 40°C to constant weight;

[0059] (2) Take by weighing 1.5g of the fiber that step (1) makes, add to 120mL concentration and be 40g / L NaIO 4 In the solution, after the fiber is fully swollen, react in a constant temperature shaking box at 50°C for 60 minutes, take out the fiber, wash it with distilled water several times, and dry it in a constant temperature drying box at 40°C to constant weight;

[0060] (3) Weigh 1.0g of the fiber prepared in step (2), add it to 80mL of pure triethylenetetramine solution, react in a constant temperature shaking box at 50°C for 6h, take out the fiber, wash it with distilled water several times, and place it in a constant temperat...

Embodiment 2

[0068] (1) Prepare 80 mL of 10% sodium hydroxide solution, then add 4.0 g of hemp fibrils to fully swell the fibers, soak for 120 min at a temperature of 30 ° C, take out the fibers, wash with distilled water several times, and dry them in a constant temperature drying oven at 40 ° C until constant Heavy;

[0069] (2) Take by weighing 3.5g of the fiber that step (1) makes, add to 70mL concentration and be 10g / L NaIO 4 In the solution, after the fiber is fully swollen, react in a constant temperature shaking box at 40°C for 240 minutes, take out the fiber, wash it with distilled water several times, and dry it in a 40°C constant temperature drying oven to constant weight;

[0070] (3) Weigh 3.0g of the fiber prepared in step (2), add it to 60mL of pure triethylenetetramine solution, react in a constant temperature shaking box at 60°C for 12h, take out the fiber, wash it several times with distilled water, and place it in a constant temperature drying oven at 40°C Dry to consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Count | aaaaa | aaaaa |

| Body length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com