Preparation method of ferroferric oxide/manganese dioxide composite microspheres

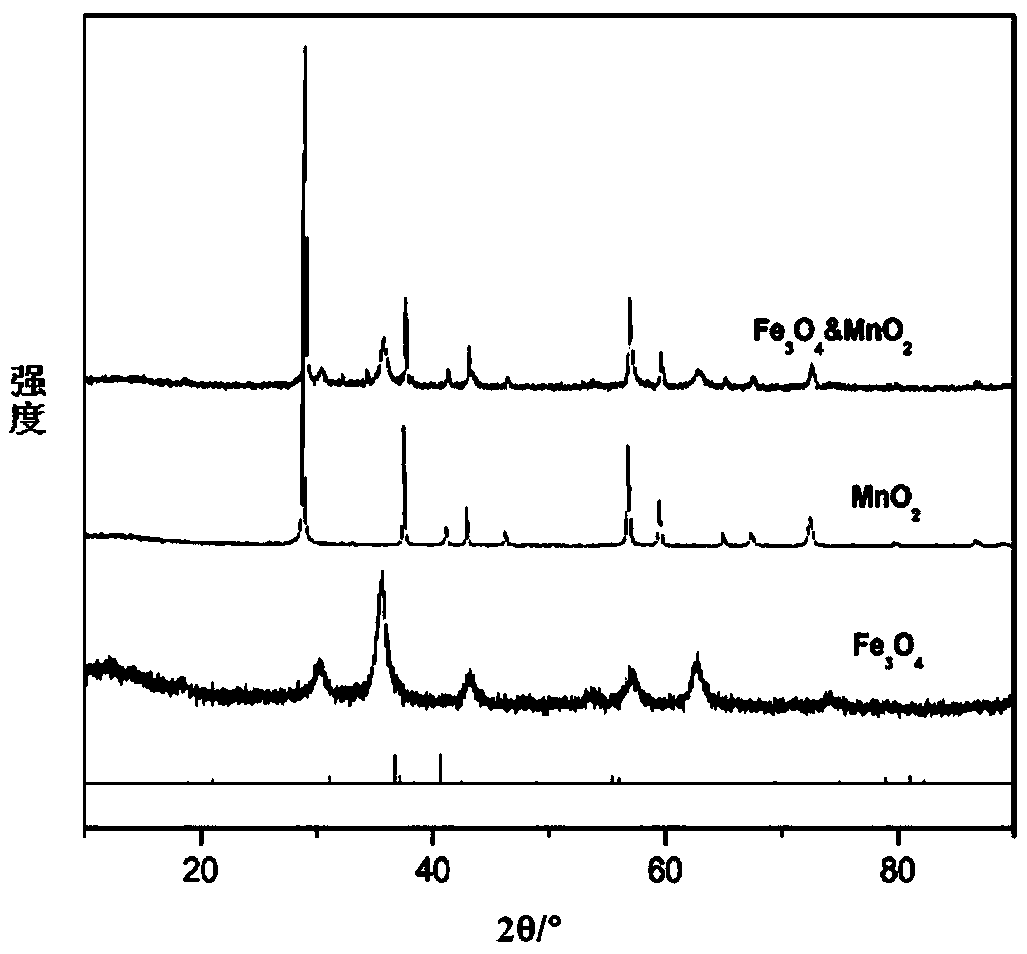

A technology of manganese dioxide microspheres and ferroferric oxide, which is applied in the direction of iron oxide/iron hydroxide, manganese oxide/manganese hydroxide, ferrous oxide, etc., can solve the problem of high preparation cost, narrow absorption frequency band, High density and other problems, achieve good microwave absorption performance, increase dielectric loss, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 3.1 g spherical ferroferric oxide nanoparticles and 1.1 g spherical manganese dioxide nanoparticles; measure 150 ml of deionized water, pour it into a ball mill tank, and then add 400 g ball mill; ball mill 12 at a speed of 400 r / min h to obtain a well-dispersed suspension; dissolve 0.5 g of polyvinylpyrrolidone (PVP) in 20 ml of deionized water, and magnetically stir for 2.5 h to obtain a clear PVP solution; add the clear PVP solution to the previously dispersed suspension In the turbid liquid, continue ball milling at 6000r / min for 6.5 hours to obtain a suspension with good dispersibility; transfer the obtained suspension to a beaker, ultrasonically disperse for 0.5 h, and then perform spray drying treatment and spray drying procedures : The peristaltic pump speed is 30 rpm, the nozzle diameter is 1 mm, the inlet air temperature is 220°C, the needle is 5 times / min, and the fan speed is 30m 3 / h; The sprayed powder is ferroferric oxide / manganese dioxide microsphere...

Embodiment 2

[0030] Weigh 3.0 g spherical Fe3O4 nanoparticles and 1.0 g spherical manganese dioxide nanoparticles; measure 150 ml of deionized water, pour it into a ball mill tank, and then add 400 g ball mill; ball mill 12 at a speed of 400 r / min h to obtain a well-dispersed suspension; dissolve 0.5 g of polyvinylpyrrolidone (PVP) in 20 ml of deionized water, and magnetically stir for 2.5 h to obtain a clear PVP solution; add the clear PVP solution to the previously dispersed suspension In the turbid liquid, continue ball milling at 6000r / min for 6.5 hours to obtain a suspension with good dispersibility; transfer the obtained suspension to a beaker, ultrasonically disperse for 0.5 h, and then perform spray drying treatment and spray drying procedures : The peristaltic pump speed is 25 rpm, the nozzle diameter is 1mm, the inlet air temperature is 200℃, the needle is 7 times / min, and the fan speed is 30m 3 / h; The sprayed powder is ferroferric oxide / manganese dioxide microspheres; the composi...

Embodiment 3

[0032] Weigh 3.0 g spherical Fe3O4 nanoparticles and 1.0 g spherical manganese dioxide nanoparticles; measure 150 ml of deionized water, pour it into a ball mill tank, and then add 400 g ball mill; ball mill 12 at a speed of 400 r / min h to obtain a well-dispersed suspension; dissolve 0.5 g of polyvinylpyrrolidone (PVP) in 20 ml of deionized water, and magnetically stir for 2.5 h to obtain a clear PVP solution; add the clear PVP solution to the previously dispersed suspension In the turbid liquid, continue ball milling at 6000r / min for 6.5 hours to obtain a suspension with good dispersibility; transfer the obtained suspension to a beaker, ultrasonically disperse for 0.5 h, and then perform spray drying treatment and spray drying procedures : The peristaltic pump speed is 20 rpm, the nozzle diameter is 0.7 mm, the air inlet temperature is 180 ℃, the needle is 7 times / min, and the fan speed is 25m 3 / h; The sprayed powder is ferroferric oxide / manganese dioxide microspheres; the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com