Method for extracting vitamin D2 from mushroom powder by vegetable oil

A technology of mushroom powder and vegetable oil, applied in solvent extraction, separation method, solid solvent extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

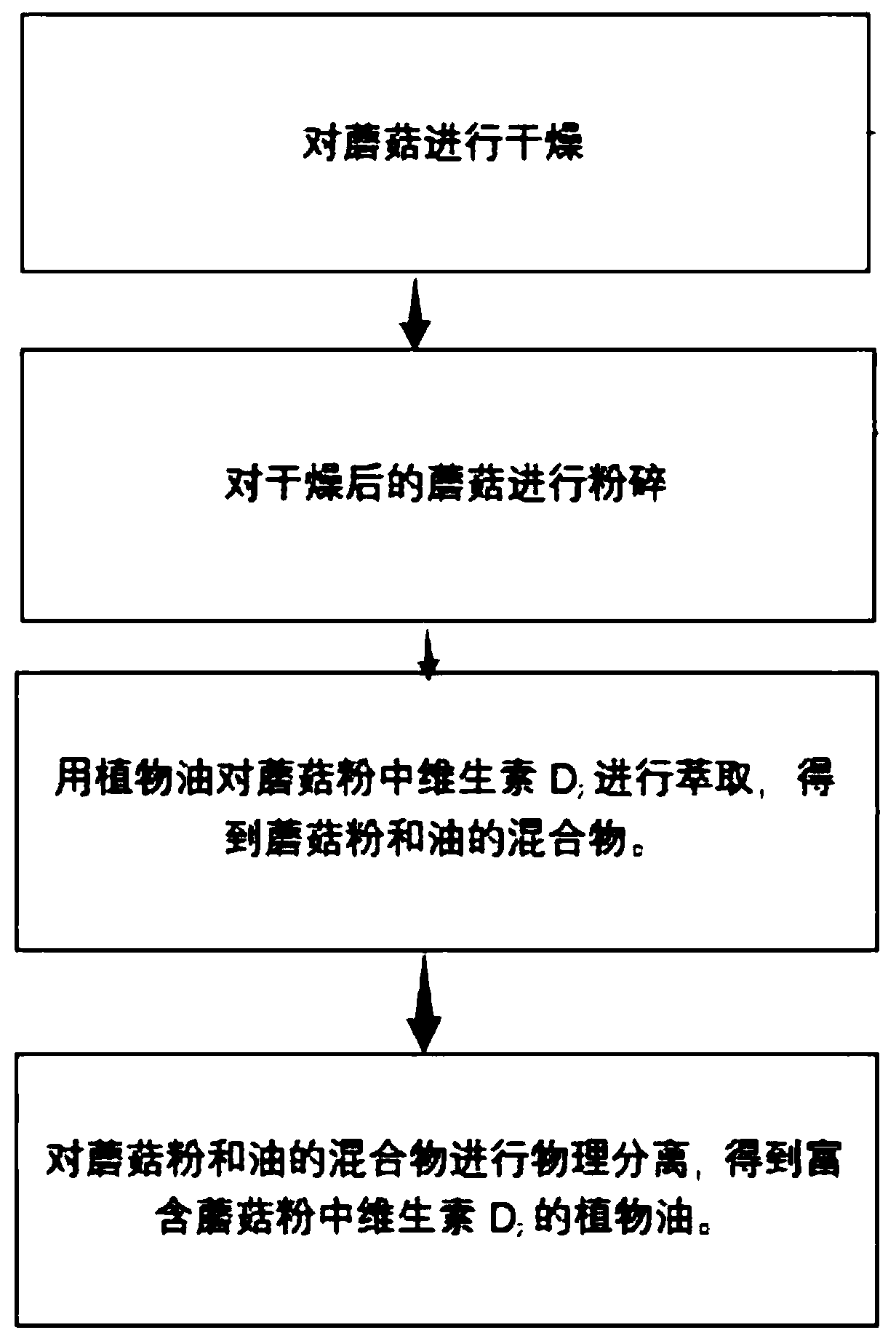

[0028] Specific implementation steps:

[0029] STP1 dries the mushrooms;

[0030] STP2 grinds the dried mushrooms;

[0031] STP3 uses vegetable oil to extract the vitamin D2 in the mushroom powder in STP2;

[0032] STP4 adopts the method of physical separation to separate the mixture of oil and mushroom powder in STP3 to obtain oil.

[0033] The aforementioned mushroom is Agaricus bisporus.

[0034] The mushrooms are pre-treated before the STP1, and the pre-processing methods include: slicing and grinding fresh mushrooms.

[0035] The drying pretreatment method of STP1 mushrooms is as follows:

[0036] Dried directly so that the moisture in the mushrooms is ≤15%;

[0037] The drying method of STP1 includes hot air drying method and vacuum freeze-drying method. The process conditions of the hot air drying method are: 30-260°C, and the time is 10-300min; the process conditions of the vacuum freeze-drying method are: freezing temperature -80-0 ℃, the degree of vacuum is 0.3...

Embodiment 2

[0044] Specific implementation steps:

[0045] STP1 dries the mushrooms;

[0046] STP2 grinds the dried mushrooms;

[0047] STP3 uses vegetable oil to extract the vitamin D2 in the mushroom powder in STP2;

[0048] STP4 adopts the method of physical separation to separate the mixture of oil and mushroom powder in STP3 to obtain oil.

[0049] The mushroom is any one of oyster mushroom, crab-flavored mushroom, pleurotus eryngii, white jade mushroom, tea tree mushroom, bisporus mushroom, shiitake mushroom, Hericium erinaceus, Bailing mushroom and Coprinus comatus.

[0050] STP1 does not process before and directly proceeds to the next step.

[0051] The drying pretreatment method of STP1 mushrooms is as follows:

[0052] Pre-drying is performed first so that the moisture in the mushrooms is between 30% and 70%, and then drying is performed so that the moisture in the mushrooms is below 15%.

[0053] The drying method of STP1 includes hot air drying method and vacuum freeze-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com