Method for extracting and purifying anti-hypoxic polysaccharides from Qaidam agaricus bitorquis

A purification method, the technology of big fat mushrooms, applied in the field of biochemistry, to achieve the effect of improving the degree of purification, improving the degree of purification, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 3. Extraction of crude polysaccharides

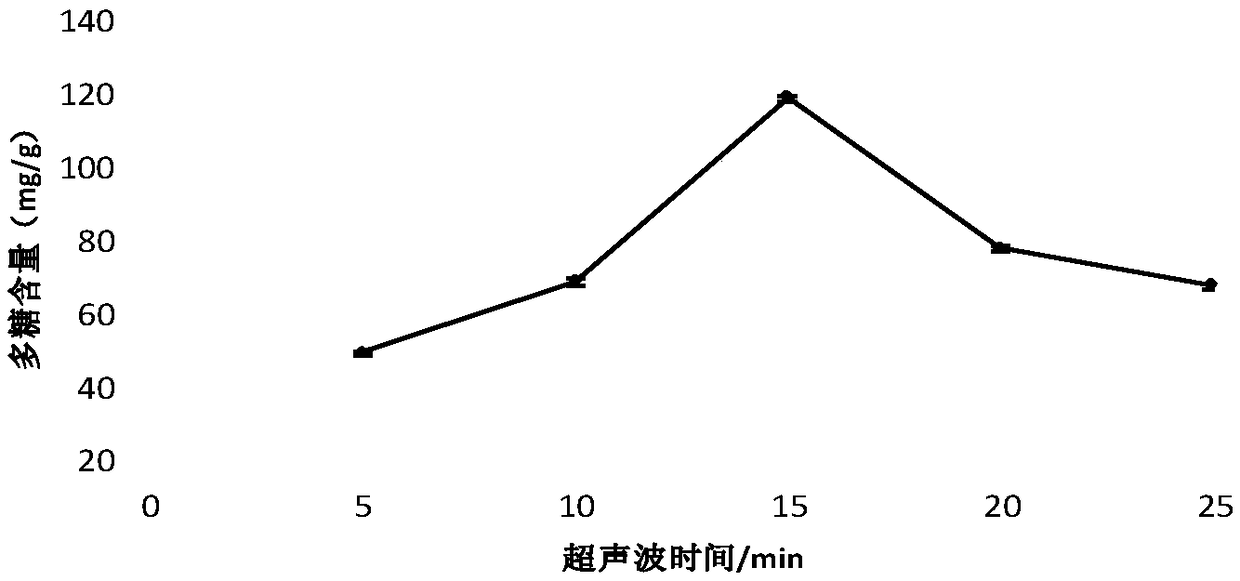

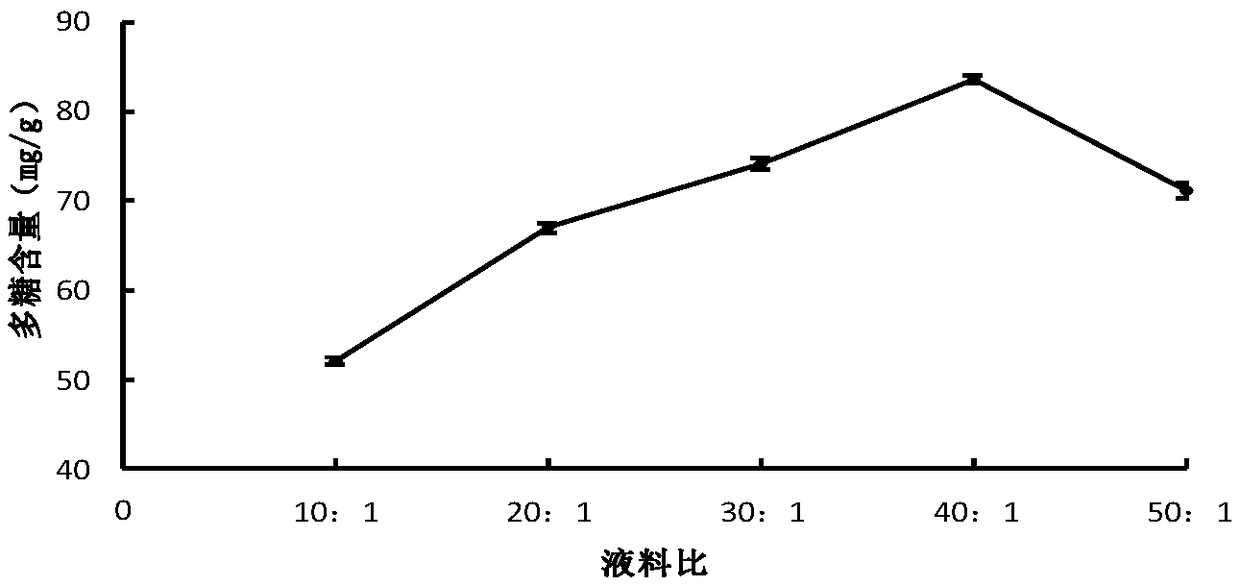

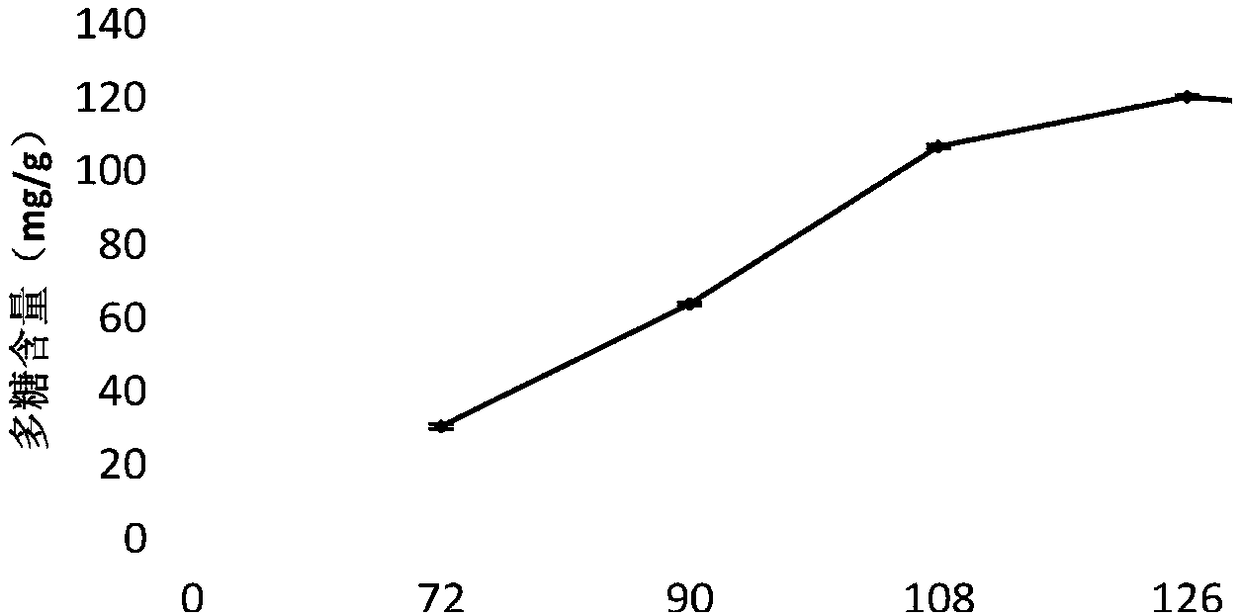

[0058] 1) Extraction: Ultrasonic-assisted water extraction method is used to filter and dry the mycelium of Qaidam big fat mushroom cultured by liquid submerged fermentation. In an ultrasonic cleaning machine, extract under the conditions of 70° C. and 126 W (45 kHz) for 1 hour, and filter the supernatant liquid for future use.

[0059] 2) Concentration: take the polysaccharide solution after suction filtration and use a rotary evaporator to concentrate at a ratio of 1:10 at a temperature of 70°C and a rotation speed of 60RPM to measure the concentration of crude polysaccharide and freeze it for later use;

[0060] 4. Purification of mycelium crude polysaccharides

[0061] 1) Pretreatment of DEAE-52 anion resin

[0062] Weigh 100g of DEAE-52 anionic resin dry powder in distilled water at a ratio of 1:5 and soak for 48 hours, rinse repeatedly to remove suspended impurities in the upper layer (after standing for 10 minutes, use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com