Special low-smell non-phenol calcium zinc stabilizer for floor and preparation method thereof

A calcium-zinc phenolate-free and low-odor technology is applied in the field of special low-odor calcium-zinc phenolate-free stabilizer and its preparation field, which can solve the problems of poor flame retardancy, poor thermal stability, etc. The effect of a high Young's modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

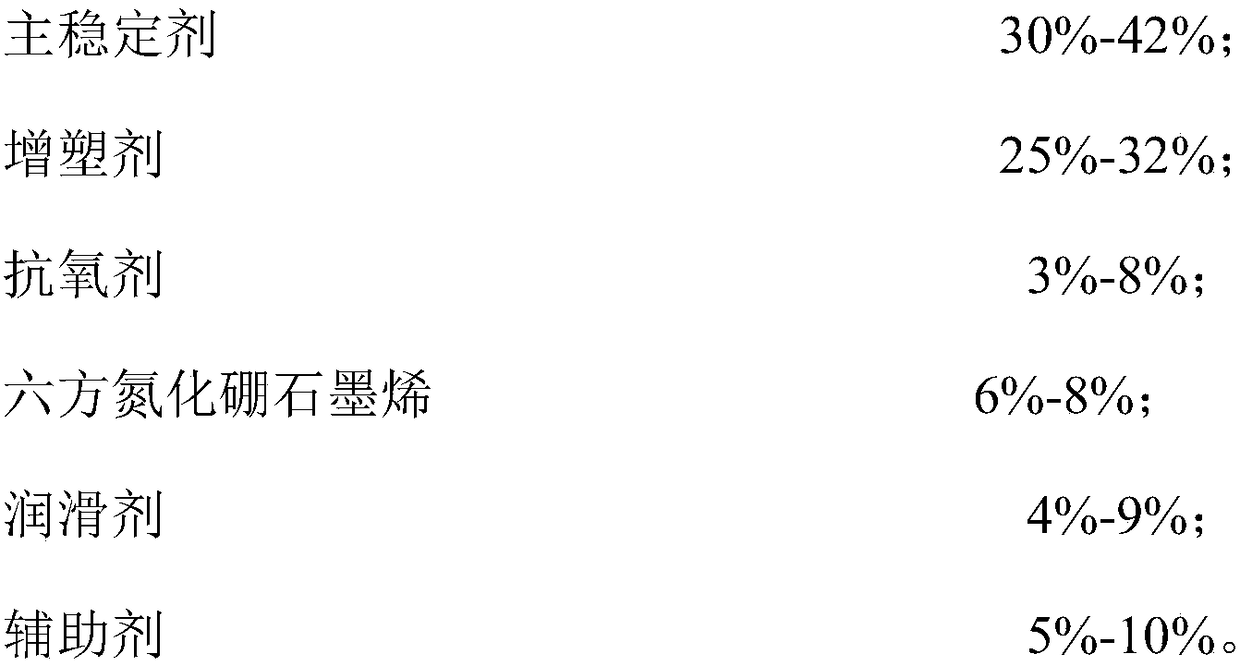

[0026] Weigh the following components:

[0027]

[0028] Prepare as follows:

[0029] (1) Add calcium stearate and zinc stearate in reaction container, and stir 60min at 60 ℃;

[0030] (2) Continue to add di-n-octyl phthalate, ethylene bisstearic acid amide, antioxidant 1010, magnesium stearate, and stir at 70°C for 60 minutes;

[0031] (3) Finally, add hexagonal boron nitride graphene, stir at 75°C for 30 minutes, and obtain a low-odor, phenol-free calcium-zinc stabilizer for floors after cooling.

Embodiment 2

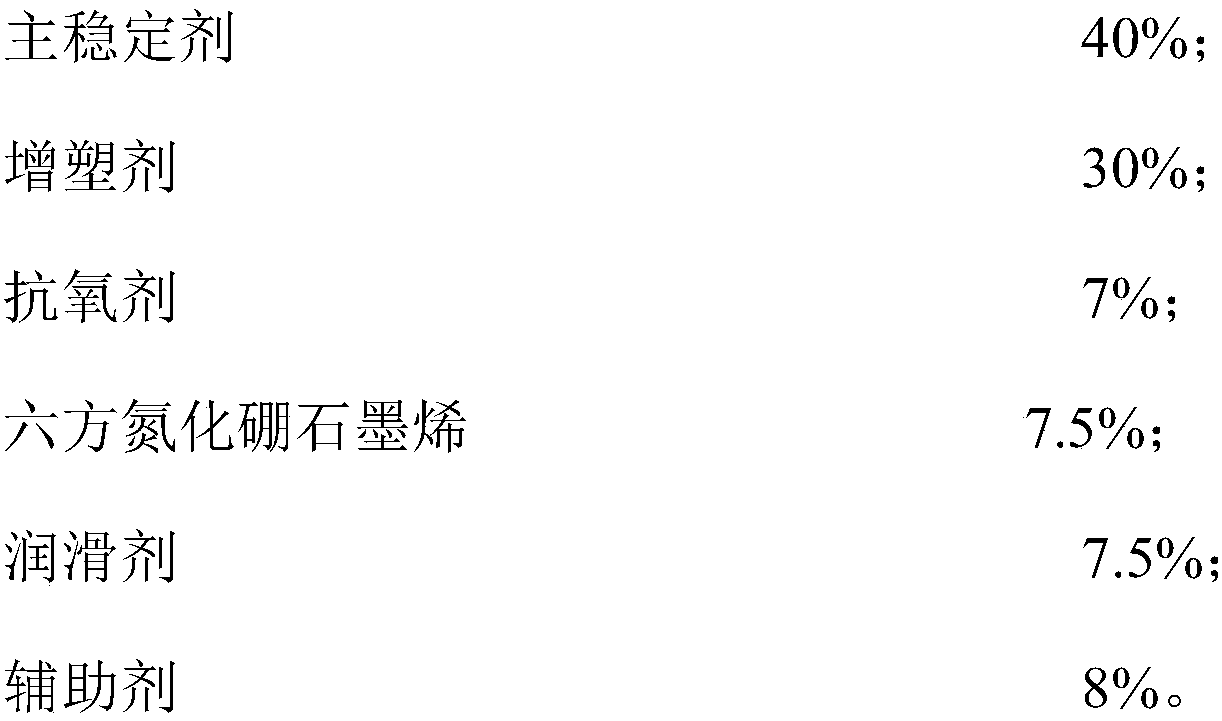

[0033] Weigh the following components:

[0034]

[0035] Prepare as follows:

[0036] (1) Add calcium laurate and zinc stearate to the reaction vessel, and stir at 70°C for 50min;

[0037] (2) Continue to add diisodecyl phthalate, paraffin, antioxidant 1076, magnesium stearate, and stir at 80°C for 55 minutes;

[0038] (3) Finally, add hexagonal boron nitride graphene, stir at 85°C for 25 minutes, and obtain a low-odor, phenol-free calcium-zinc stabilizer for floors after cooling.

Embodiment 3

[0040] Weigh the following components:

[0041]

[0042] Prepare as follows:

[0043] (1) Add calcium isooctanoate and zinc phosphite into the reaction vessel, and stir at 80°C for 40 minutes;

[0044] (2) Continue to add diisodecyl phthalate, polyethylene wax, antioxidant 164, aluminum hydroxide, and stir at 80°C for 55min;

[0045] (3) Finally, add hexagonal boron nitride graphene, stir at 85°C for 25 minutes, and obtain a low-odor, phenol-free calcium-zinc stabilizer for floors after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com