Method for preparing Cu-Cr alloy by means of magnetic field/ultrasonic field coupling

A technology of ultrasonic field and cu-cr, which is applied in the field of preparing Cu-Cr alloy by magnetic field/ultrasonic field coupling, to achieve the effect of reducing content, simple preparation process and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

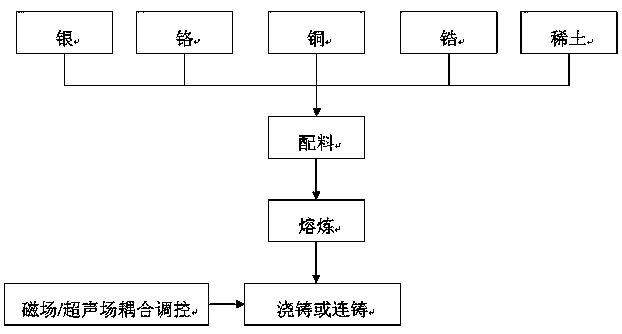

[0021] A kind of method utilizing magnetic field / ultrasonic field coupling to prepare Cu-Cr alloy, concrete steps are as follows:

[0022] 1. Ingredients: The formula of Cu-Cr alloy is calculated by mass percentage: chromium: 5, zirconium: 0.001, silver: 0.01, rare earth cerium: 0.001, copper: balance; according to the requirements of chemical composition, the electrolytic Copper, pure chromium or chromium-containing alloys, pure zirconium or zirconium-containing alloys, pure silver or silver-containing alloys, cerium metal or cerium-containing alloys are mixed to obtain ingredients;

[0023] 2. Melting: Put the prepared ingredients into the medium-frequency induction furnace for melting, use an infrared thermometer to measure the melt temperature in real time, heat it to about 100°C above the liquidus temperature, and keep it warm to ensure that the raw materials are fully melted. followed by casting;

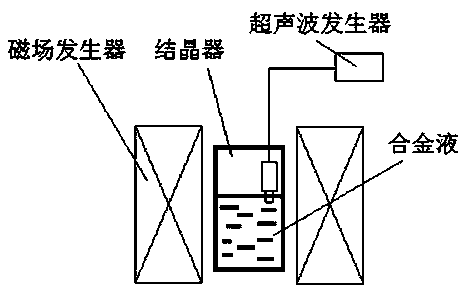

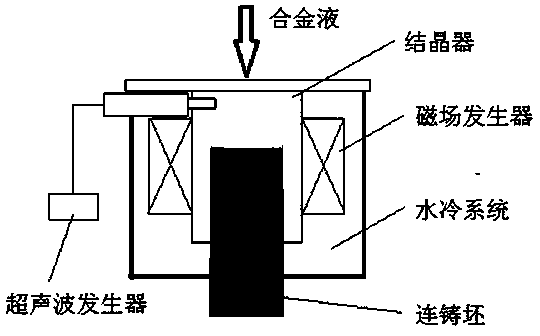

[0024] 3. Casting: After the alloy temperature drops to about 30°C above...

Embodiment 2

[0027] A kind of method utilizing magnetic field / ultrasonic field coupling to prepare Cu-Cr alloy, concrete steps are as follows:

[0028] 1. Ingredients: The formula of Cu-Cr alloy is calculated by mass percentage: chromium: 18, zirconium: 0.500, silver: 2.00, rare earth lanthanum: 0.002, copper: balance; according to the requirements of chemical composition, the electrolytic Copper, pure chromium or chromium-containing alloys, pure zirconium or zirconium-containing alloys, pure silver or silver-containing alloys, lanthanum metal or lanthanum-containing alloys are mixed to obtain ingredients;

[0029] 2. Melting: Put the prepared ingredients into the intermediate frequency induction furnace, measure the melt temperature in real time with an infrared thermometer, heat it to about 100°C above the liquidus temperature, and keep it warm to ensure that the raw materials are fully melted. casting;

[0030] 3. Casting: After the alloy temperature drops to about 30°C above the liqui...

Embodiment 3

[0033] A kind of method utilizing magnetic field / ultrasonic field coupling to prepare Cu-Cr alloy, concrete steps are as follows:

[0034] 1. Ingredients: The formula of Cu-Cr alloy is calculated by mass percentage: chromium: 8, zirconium: 0.100, silver: 0.50, rare earth yttrium: 0.01, copper: balance; according to the requirements of chemical composition, the electrolytic Copper, pure chromium or chromium-containing alloys, pure zirconium or zirconium-containing alloys, pure silver or silver-containing alloys, yttrium metal or yttrium-containing alloys mixed to obtain ingredients;

[0035] 2. Melting: Put the prepared ingredients into a high-frequency induction furnace, use an infrared thermometer to measure the melt temperature in real time, heat it to about 100°C above the liquidus temperature, and keep it warm to ensure that the raw materials are fully melted. After standing to cast;

[0036] 3. Casting: After the alloy temperature drops to about 30°C above the liquidus l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com