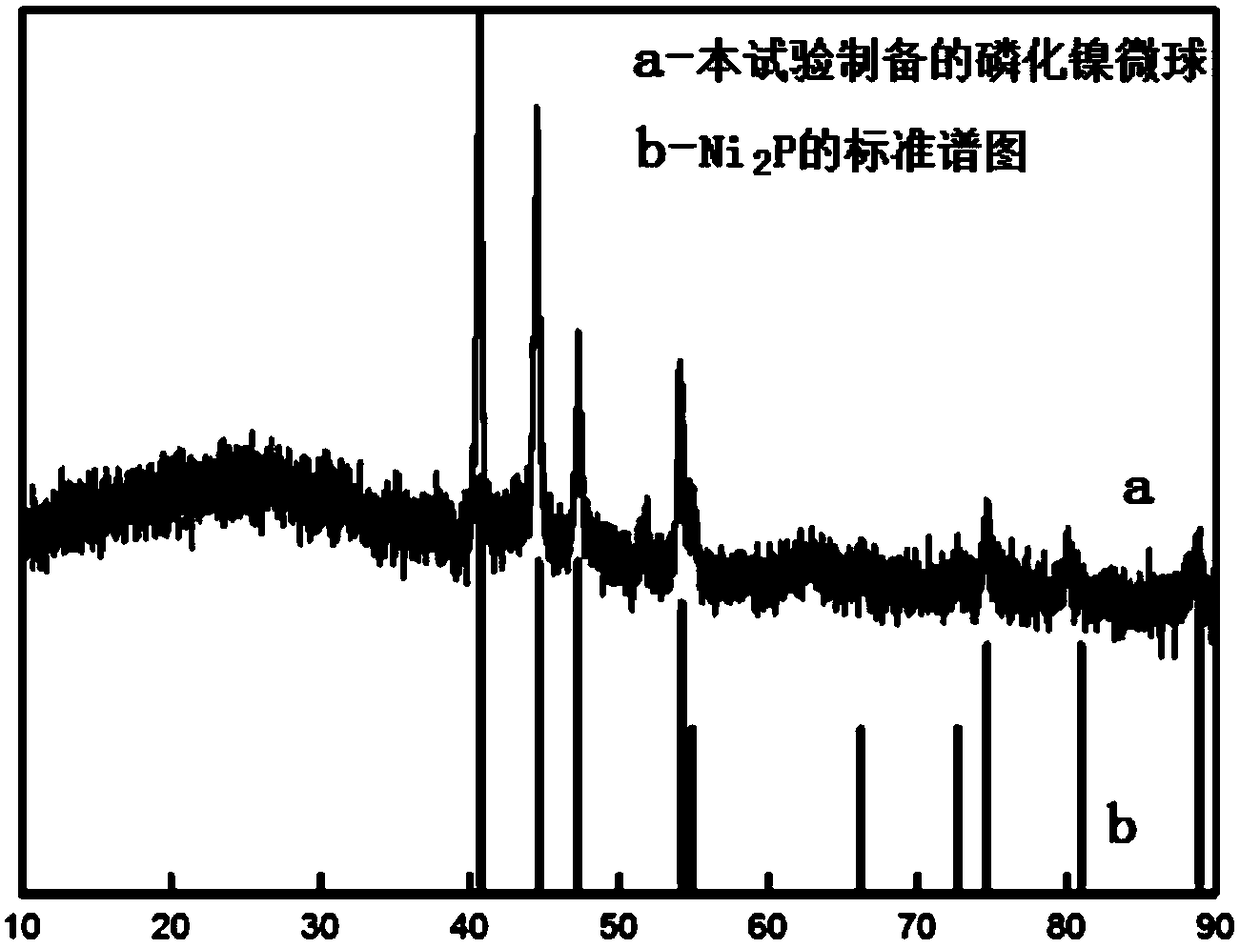

Preparation method of nickel phosphide microsphere with multilevel structure

A technology of nickel phosphide and microspheres, applied in structural parts, electrochemical generators, nanotechnology for materials and surface science, etc., can solve the problem of small specific surface area of nickel phosphide particles and vibration of nano-scale nickel phosphide Low density and other problems, to achieve the effect of high tap density, mild conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of the nickel phosphide microsphere of multi-level structure of the present embodiment, carry out according to the following steps:

[0015] 1. Preparation of precursor:

[0016] According to the molar ratio of nickel acetate and urea is 1: (5-8), nickel acetate and urea are added to water, stirred and dissolved to obtain a mixed solution; then the mixed solution is kept in a water bath with a temperature of 80-90°C for 3 ~ 5 hours, after cooling, centrifuge to collect the solid phase, wash it clean, and then vacuum dry at a temperature of 60-80°C to obtain a precursor;

[0017] 2. Preparation of nickel phosphide microspheres with multi-level structure:

[0018] Put the precursor obtained in step 1 into a porcelain boat, put sodium hypophosphite into another porcelain boat, put the two porcelain boats together into a quartz tube, and continuously pass argon gas protection into the quartz tube, wherein The porcelain boat ...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar ratio of nickel acetate to urea in step 1 is 1: (6-7). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of nickel acetate in the mixed solution in step 1 is 4-5 g / L, and the concentration of urea is 7-9 g / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com