Pre-fermented material special for antibiotic-free cold-pelleting and preparation method of complete pellet feed thereof

A technology of pre-fermented feed and pellet feed, which is applied in the forming or processing of animal feed, animal feed, animal feed, etc., which can solve the problems of poor feasibility of antibiotic-free feed, inability to realize industrial production, and inability to meet the average transfer cycle, etc. To achieve the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

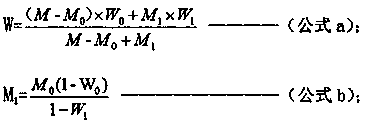

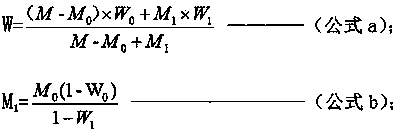

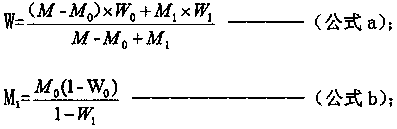

[0057] This example takes the production of 100 tons of 25-60kg lean fattening pig non-cold-resistant granulated full-price pellet feed in Huangshi Jianong Biotechnology Co., Ltd. in May 2017 as an example to explain the present invention in detail. The initial complete feed formula for fattening pigs consists of the following raw materials in parts by weight: corn: 64, soybean meal: 11, bran: 8, cottonseed meal: 7, rapeseed meal: 5, and premix: 4. The initial average moisture content of full-price feed formula is 12.5% in the present embodiment, and bran, cottonseed meal, rapeseed meal are selected to ferment according to formula ratio in the present embodiment, and the moisture content of the pre-fermented feed that is made is 28%, and this In the embodiment, the final moisture content of the full-price powder required to enter the granulator is 16.1%, and the total weight of the full-price feed M=100 tons, the initial moisture content of the full-price feed W 0 =12.5%, th...

Embodiment 2

[0082] This embodiment takes the production of 100 tons of 5-12-week-old yellow-feathered broiler non-cold-resistant granulated full-price pellet feed in Huangshi Jianong Biotechnology Co., Ltd. in August 2017 as an example to explain the present invention in detail. The initial full-price feed formula for yellow feather broilers consists of the following raw materials in parts by weight: corn: 69, soybean meal: 16.7, cotton meal: 8, meat and bone meal: 3, calcium hydrogen phosphate: 1.6, stone powder: 0.4, table salt: 0.3, pre- Mixture: 1. In this embodiment, the initial average moisture content of the full-price feed formula is 12%. In this embodiment, soybean meal and cotton meal are selected for fermentation, and the moisture content of the pre-fermented material is 30%. In this embodiment, it is required to enter the granulator The final moisture content of the full-price powder is 17%, and the total weight of the full-price feed M=100 tons, the initial moisture content o...

Embodiment 3

[0107] This example explains the present invention in detail by taking the production of 10 tons of cold-resistant granulated full-price pellet feed for herring in Huangshi Jiaxing Biotechnology Co., Ltd. in January 2018 as an example. The initial full-price feed formula for herring in this example is given by The raw material composition is as follows in parts by weight: fish meal: 20, meat and bone meal: 1, soybean meal: 15, cotton meal: 10, rapeseed meal: 20, bran: 10, corn germ meal: 10, starch: 8, premix: 6 . In this embodiment, the initial average moisture content of the full-price feed formula is 12%. In this embodiment, soybean meal, cotton meal, rapeseed meal, bran, and corn germ are selected according to the ratio of 1:1:1:1:1 by weight. The dregs are fermented, and the moisture content of the pre-fermented feed is 25%. In this embodiment, the final moisture content of the full-price powder that enters the granulator is required to be 15%. Feed initial moisture W 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com