Method for greenly and efficiently extracting bergamot flavone and bergamot flavone

A bergamot flavonoid and extraction technology, which is applied in the direction of solid solvent extraction, can solve the problems of high manufacturing cost and maintenance cost, inconvenient extraction solvent recovery, low extraction efficiency, etc., and achieve high product quality, shorten extraction and separation time, and high-efficiency extraction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

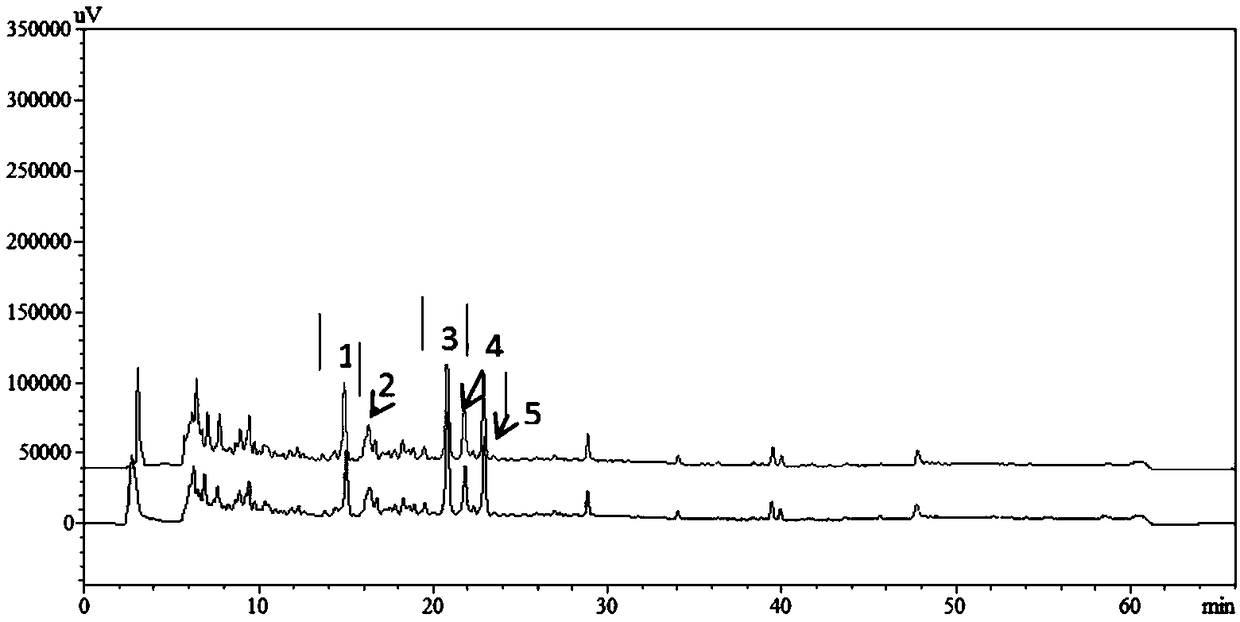

Image

Examples

Embodiment 1

[0044] Embodiment 1 continuous phase-change extraction process of bergamot flavonoids

[0045]A green and efficient method for extracting bergamot flavonoids, comprising the following steps:

[0046] S1. After pulverizing the bergamot to 30 mesh, dry it with hot air at 50°C until the water content is 20%, to obtain bergamot powder, which is degreased by continuous phase change;

[0047] S2. The bergamot slag obtained in S1 is subjected to continuous phase change extraction to obtain a bergamot flavonoid product;

[0048] Wherein, the process condition of the continuous phase change extraction described in step S2 is:

[0049] S21. Extraction: Put the bergamot residue into the extraction device, use ethanol as the extraction agent, and compress the extraction agent into a liquid under the conditions of ethanol concentration of 85%, extraction temperature of 80°C, and extraction pressure of 0.2Mpa, and use 20L / h The flow rate flows through the extraction device, and the contin...

Embodiment 2

[0054] The research of embodiment 2 bergamot flavonoids continuous phase-change extraction process

[0055] 1. On the basis of the single factor, choose A ethanol concentration, B extraction temperature, and C extraction time as independent variables, each factor takes 3 levels, coded by -1, 0, +1, and continuous The response value (Y) of variable extraction bergamot flavonoid extraction rate was designed using Design-Expert8.0.6 software to design a three-factor three-level response surface analysis test, with a total of 17 test points, of which 12 were analysis factors and 5 were for center tests. to estimate the error. The coded value and real value of each factor are shown in Table 1.

[0056] Table 1

[0057]

[0058] 2. Continuous phase change extraction of bergamot flavonoids response surface test and results are shown in Table 2.

[0059] Table 2

[0060]

[0061]

[0062] 3, adopt Design-Expert software to carry out multiple regression fitting to the resp...

Embodiment 3

[0071] Example 3 Research on the traditional ethanol reflux extraction process of bergamot flavonoids

[0072] 1. On the basis of single factor, three factors of ethanol concentration (A), reflux time (B) and solid-liquid ratio (C) are taken as independent variables. Since the extraction temperature does not change significantly, it is set at 80°C. According to Box- Behnken center combination design principle, taking the extraction rate of bergamot flavonoids (Y) as the response value. Design-Expert 8.0.6 software was used to design a three-factor and three-level response surface analysis test, with a total of 17 test points, of which 12 were analysis factors and 5 were center tests to estimate errors. The coded value and real value of each factor are shown in Table 4.

[0073] Table 4

[0074]

[0075] 2. Continuous phase change extraction of bergamot flavonoids response surface test and results are shown in Table 5.

[0076] table 5

[0077]

[0078] 3, test result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com