MEDC (Microbial Electrolytic Desalting Cell) reactor device

A microbial electricity and reactor technology, which is used in biological water/sewage treatment, electrochemical biological combined treatment, water pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

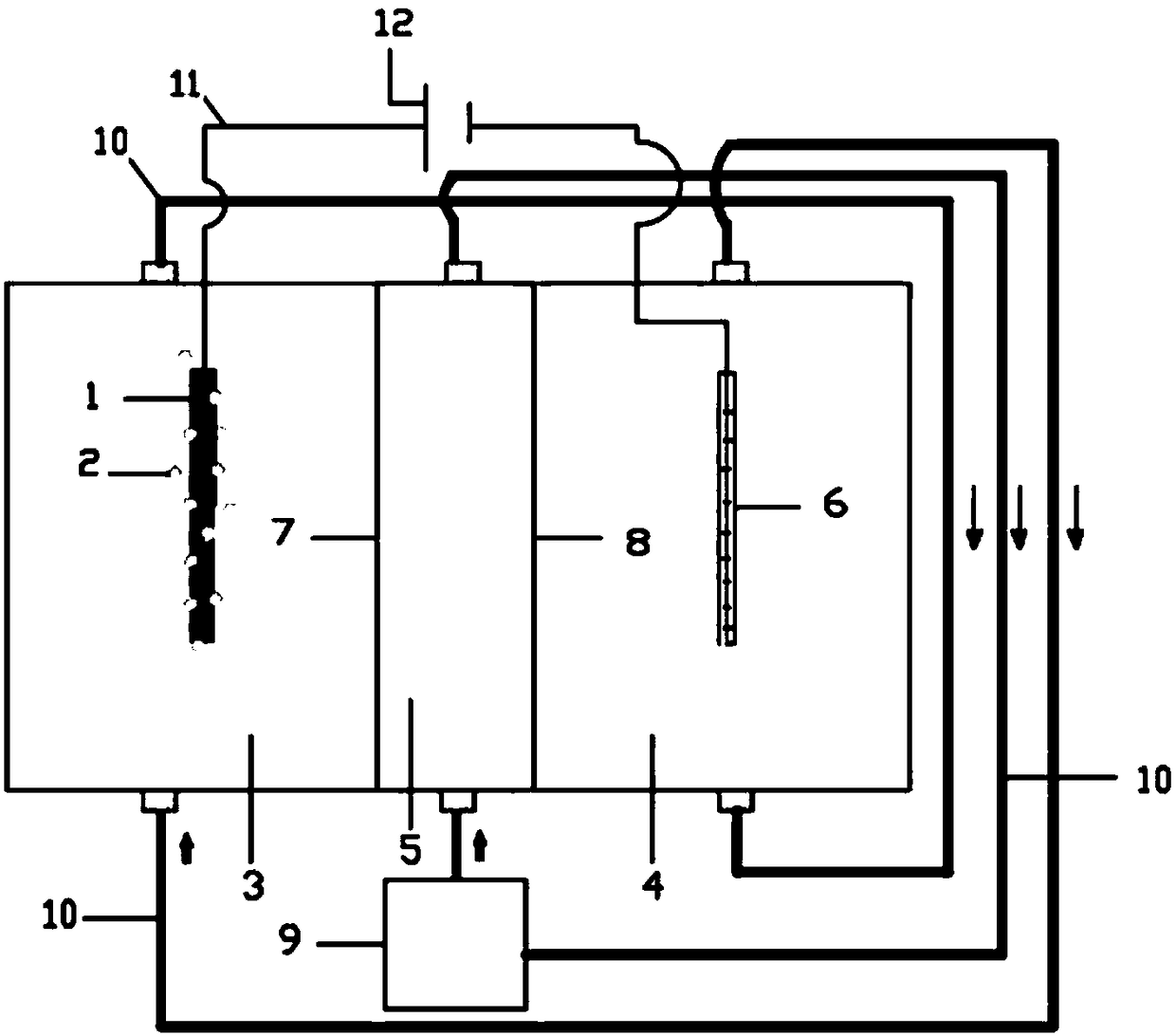

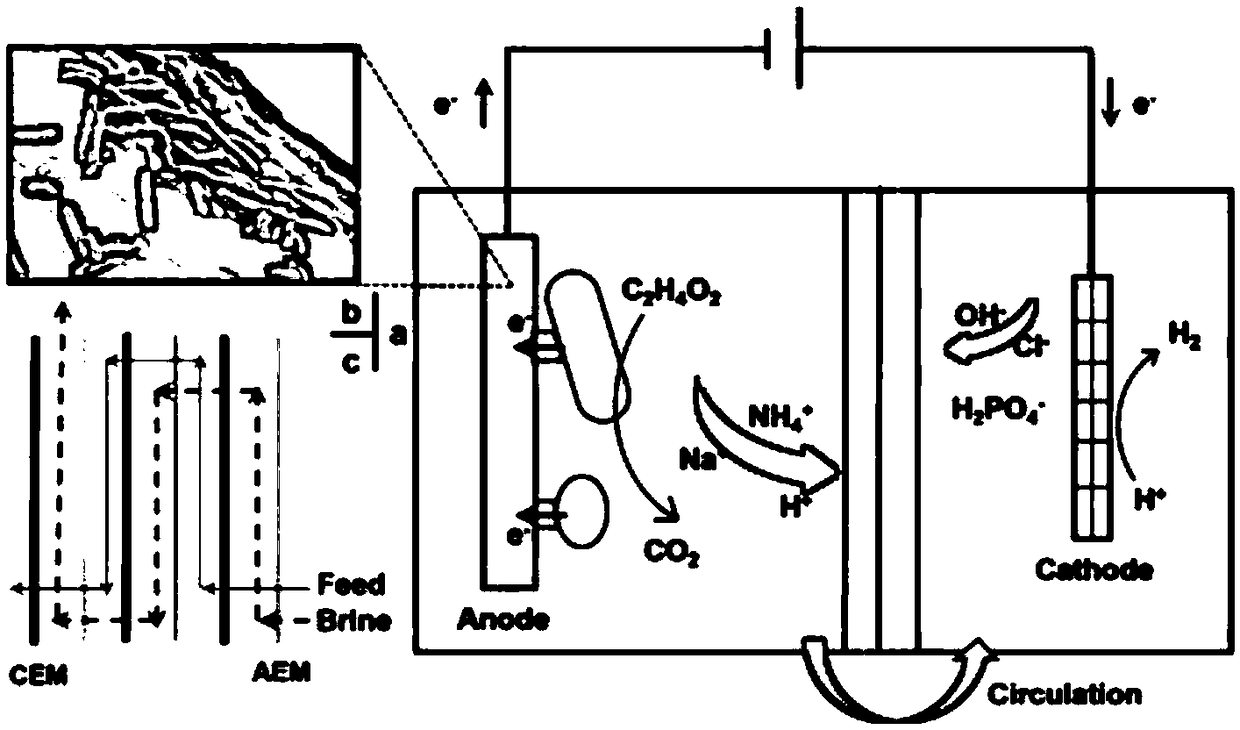

[0028] Such as figure 1 As shown, a microbial electrolytic desalination tank reactor device includes an anode chamber 3 and a cathode chamber 4. One or more sets of ion exchange membrane pairs (IEMs membrane pairs) are arranged between the anode chamber 3 and the cathode chamber 4, and the anode A bio-carbon felt electrode 1 is provided in the chamber 3, and electricity-producing microorganisms 2 are provided in the anode chamber 3, such as figure 2 As shown in b, the cathode chamber 4 is provided with a stainless steel mesh electrode 6, the bio-carbon felt electrode 1 is connected to the stainless steel mesh electrode 6 through a wire 11 via an external voltage 12, and the anode chamber 3 and the cathode chamber 4 are connected by a silicone tube 10 to form a closed loop;

[0029] The ion exchange membrane membrane pair includes a cation exchange membrane (CEM) 7 close to the anode compartment 3 and an anion exchange membrane (AEM) 8 close to the cathode compartment 4. There are...

Embodiment 2

[0032] A microbial electrolytic desalination tank reactor device. The structure is shown in Example 1. The difference is that the ion exchange membrane membrane pair is a group, that is, a single membrane pair structure. The biological carbon felt in the biological carbon felt electrode 1 is used The anaerobic sludge of the sewage treatment plant and the bio-carbon felt inoculated with the effluent of mature microbial fuel cell in the laboratory. The product room 5 uses a silicone tube 10 to connect with a blue mouth bottle 9 to form a closed loop. One of the two adjacent ion exchange membranes The thickness of the intervening chamber is preferably 2 mm, the flow rate of the solution in the anode chamber 3 and the cathode chamber 4 is 5.02 mL / min, and the flow rate of the solution in the product chamber 5 is 6 mL / min.

[0033] In Example 2, the chemical oxygen demand (COD) removal effect of sewage is better under different voltages, all reaching 78% or more.

Embodiment 3

[0035] A microbial electrolytic desalination tank reactor device. The structure is shown in Example 1. The difference is that the external voltage is 0.8V. In Example 3, the removal rates of nitrogen and phosphorus are 25.8±15.9% and 19.1±6.5%, respectively. , The recovery rate is 3.4±2% and 21.5±3.5%, the batch experiment current peak value is 1.5±0.15mA, the power consumption is 31.65±0.22C, and the coulombic efficiency is 5.44±0.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com