Method for producing tilmicosin and tilmicosin phosphate by utilizing tylosin fermentation broth

A technology of tilmicosin phosphate and tylosin, which is applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of unsuitability for large-scale industrial production, difficulty in ensuring product quality, and high safety requirements. Achieve the effect of short and efficient production process route, reduce solvent consumption, and reduce three waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

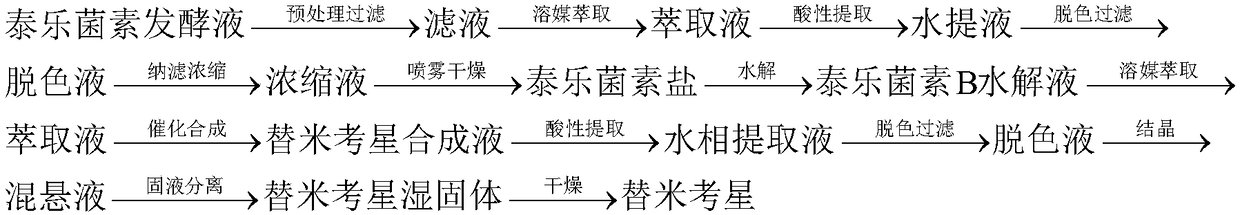

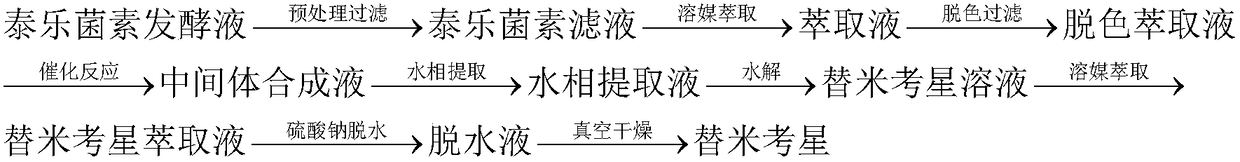

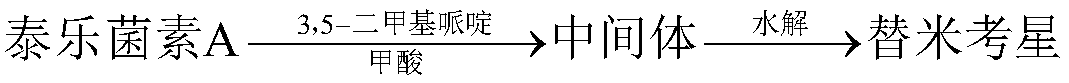

Method used

Image

Examples

Embodiment 1

[0061] Tylosin fermentation liquid obtained by fermentation method 100m 3 , the titer of tylosin is 15600u / ml, add concentrated sulfuric acid while stirring, adjust the pH value of the fermentation broth to 2.5, then raise the temperature to 65-75°C, keep it warm for 1 hour, and determine tylosin A by high performance liquid chromatography The residual content is 1.21%, and the area ratio of Tylosin B reaches 98.79%. Add filter aid diatomaceous earth 0.5% (W / V) then in fermented liquid; Continue to stir 0.5 hour; Filter through plate frame and pass into a certain amount of water washing filter cake to obtain Tylosin B filtrate 125m 3 , The titer is 11826u / ml.

[0062] Add Tylosin B filtrate to about 40m 3 Butyl acetate, while stirring, add 20% sodium hydroxide solution, control the pH value of the aqueous phase at 11-12, operate the stirring speed at 15 rpm during the pH adjustment process, and continue stirring for 0.5 hours after the pH reaches the control range; stop stir...

Embodiment 2

[0065] Tylosin fermentation liquid obtained by fermentation method 102m 3 , the titer of tylosin is 13600u / ml, add concentrated sulfuric acid while stirring, adjust the pH value of the fermentation broth to 2.5, then raise the temperature to 65-75°C, keep it warm for 1 hour, and measure the residue of tylosin A by high performance liquid chromatography 1.25%, the area ratio of Tylosin B reached 98.75%. Then add the filter aid perlite 0.5% (W / V) in the fermented liquid; Continue to stir for 0.5 hour; Filter through the plate frame and feed a certain amount of water to wash the filter cake to obtain the tylosin B filtrate 129m 3 , The titer is 10216u / ml.

[0066] Add Tylosin B filtrate to about 40m 3 Butyl acetate, while stirring, add 20% sodium hydroxide solution, control the pH value of the aqueous phase at 11-12, operate the stirring speed at 15 rpm during the pH adjustment process, and continue stirring for 0.5 hours after the pH reaches the control range; stop stirring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com