Preparation method for high-strength high-thermal-stability water-based varnish

A water-based varnish and high-strength technology, which is applied in the field of synthetic resin preparation, can solve the problems of poor thermal stability, insufficient wear resistance, and poor strength of varnish, and achieve the effects of stable internal structure, improved strength, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

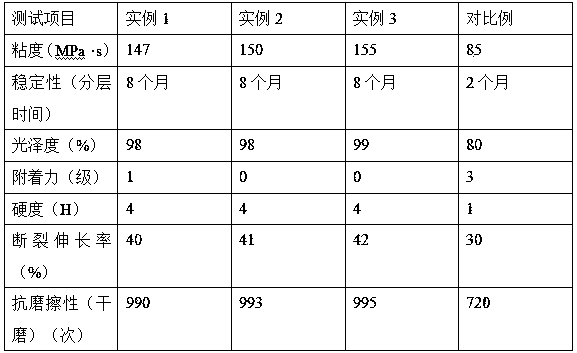

Examples

Embodiment Construction

[0022] In terms of parts by weight, weigh 10-14 parts of graphite, 6-8 parts of potassium permanganate powder and 20-24 parts of concentrated sulfuric acid with a mass fraction of 80-90% into a beaker, and put the beaker into a In a water bath at ~5°C, stir with a stirrer at a speed of 300~350r / min for 70~90min, then increase the temperature of the water bath to 30~33°C, and react at a constant temperature for 2.5~2.7h to obtain a suspension; mix the above suspension with Put deionized water into the beaker at a mass ratio of 1:2 to obtain a mixed solution, then place the beaker in a water bath with a water bath temperature of 85-90°C, then add anhydrous ethanol with a mixed solution mass of 25-30% to the beaker and After mixing and stirring at a speed of 400-450r / min for 20-30min, add 10-13% of the mixed liquid mass fraction of acetic acid solution with a mass fraction of 80-90%, and mix and stir at a speed of 400-450r / min for 20-30min Obtain a solid-liquid mixture; filter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com