Preparation method of graphene composite wave absorbing material based on 5G communication and application of graphene composite wave absorbing material

A graphene composite and wave-absorbing material technology is applied in the field of wave-absorbing materials, which can solve the problems that wave-absorbing materials cannot be satisfied, carbonyl iron powder has high density, poor temperature stability, etc., and achieves good absorption performance, light surface density, and wave absorption. thin coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

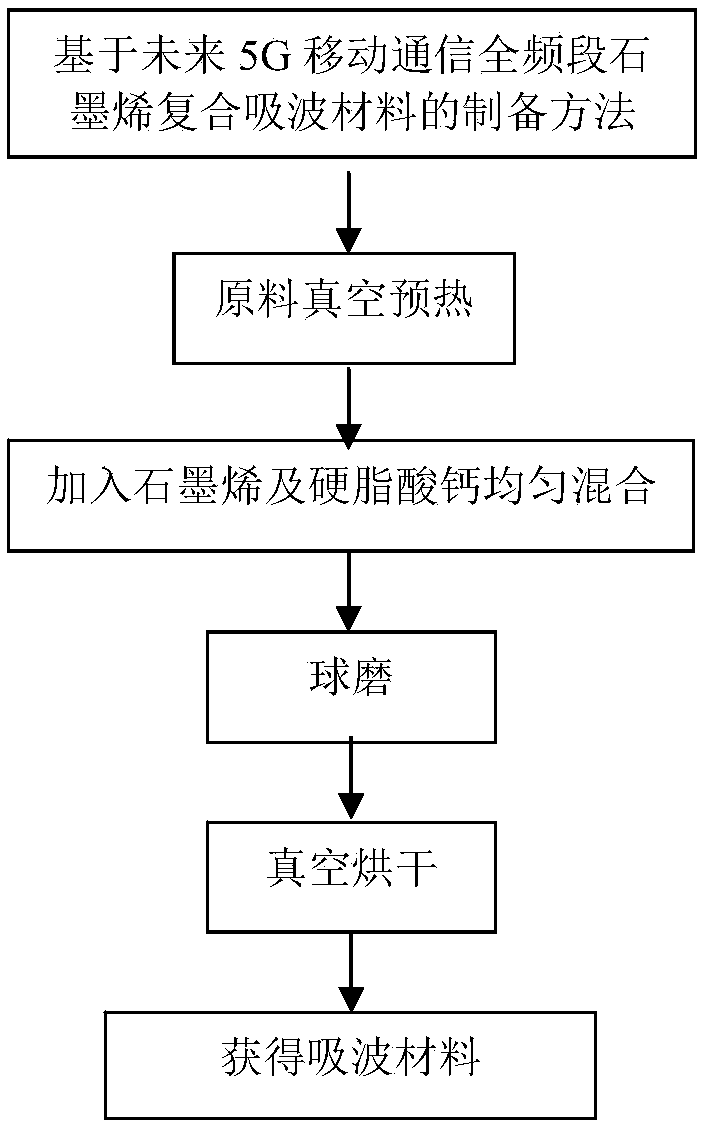

[0042] A preparation method of a graphene composite wave-absorbing material based on the full-band of future 5G mobile communication is as follows:

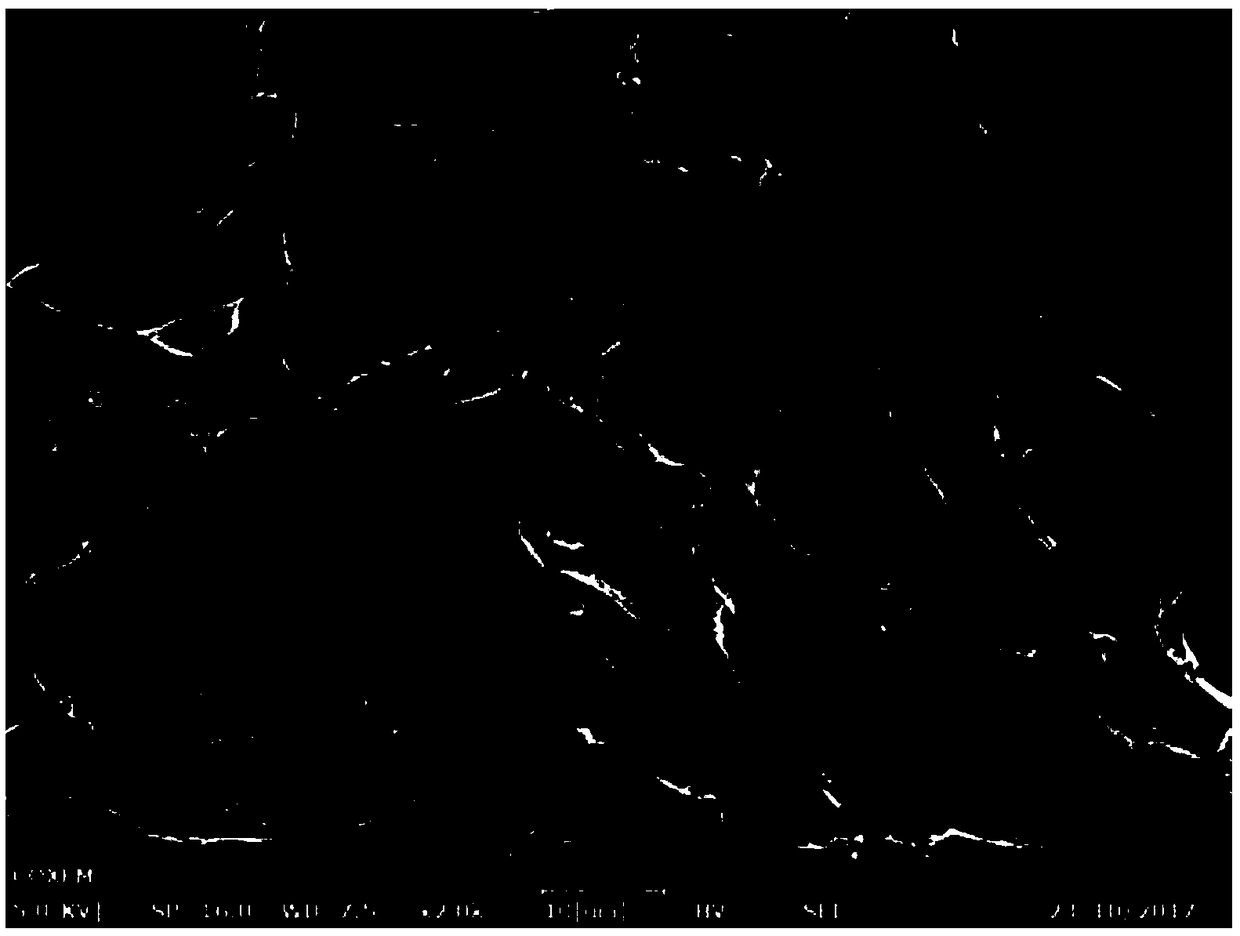

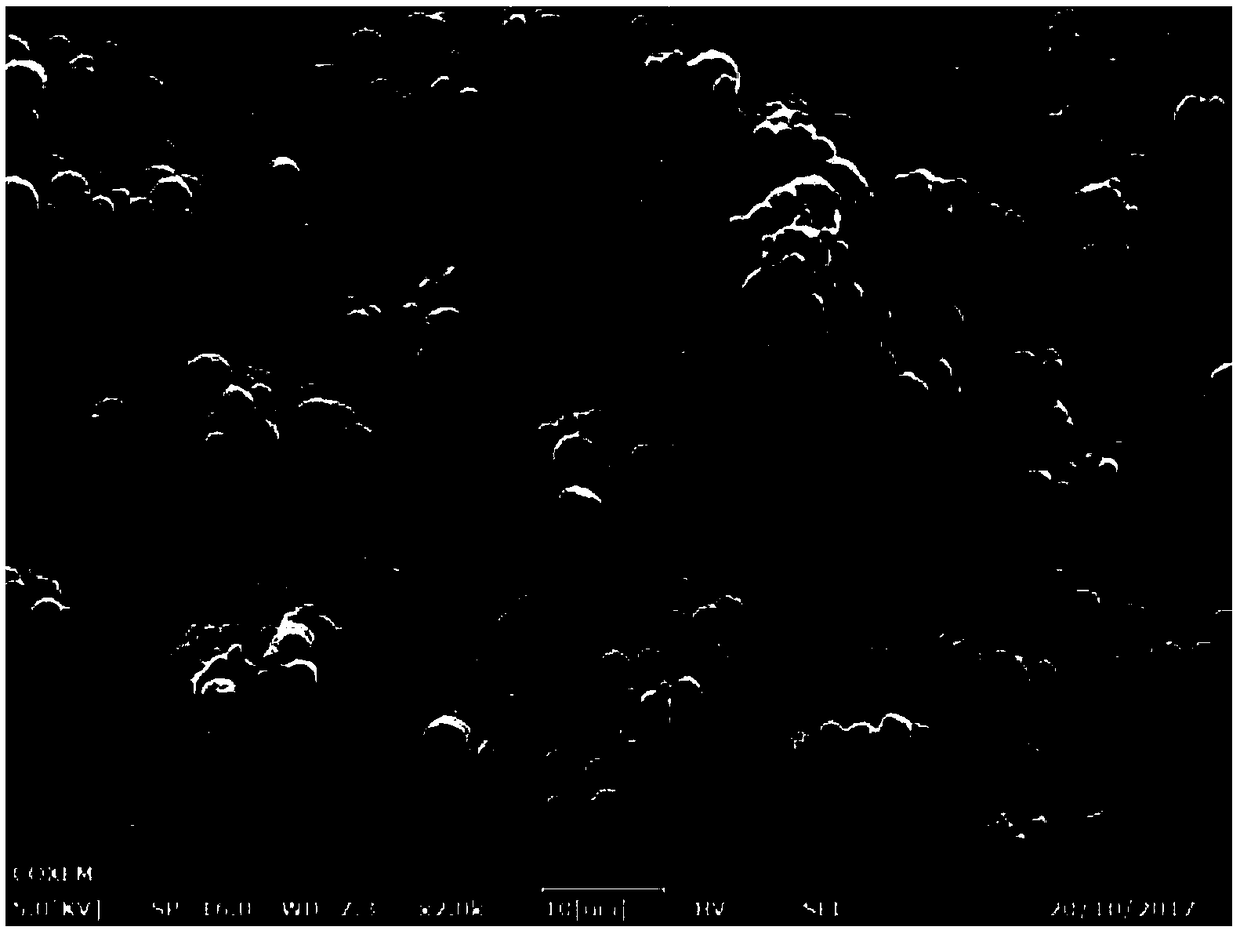

[0043] First, preheat the raw material of carbonyl iron powder, preheat the raw material under the protection of argon at 100°C for 2 hours; mix 4.9g of carbonyl iron powder raw material and bearing steel balls according to the mass ratio of material ball 1:10 Put it into a ball mill jar, wherein the bearing steel balls are composed of small balls with a diameter of 6mm and middle balls with a diameter of 8mm. The mass ratio of the small balls to the middle balls is 1:1. Add 0.1g graphene oxide, 0.01g Calcium stearate, and add 50mL of absolute ethanol to immerse the raw material, stir evenly with a glass rod, and then seal it into a pendulum ball mill for ball milling. The ball milling time is 1 hour. The ball milling changes the shape of the spherical carbonyl iron powder to have a certain Flaky particles with aspect ratio, and ...

Embodiment 2

[0046] A preparation method of a graphene composite wave-absorbing material based on the full-band of future 5G mobile communication is as follows:

[0047] First, preheat the raw material of carbonyl iron powder, preheat the raw material under the protection of argon at 100°C for 2 hours; mix 4.9g of carbonyl iron powder raw material and bearing steel balls according to the mass ratio of material ball 1:10 Put it into a ball mill jar, wherein the bearing steel balls are composed of small balls with a diameter of 6mm and middle balls with a diameter of 8mm. The mass ratio of the small balls to the middle balls is 1:1. Add 0.1g graphene oxide, 0.01g Calcium stearate, and add 50mL of absolute ethanol to immerse the raw material, stir evenly with a glass rod, and then seal it into a pendulum ball mill for ball milling. The ball milling time is 2 hours. The ball milling changes the shape of the spherical carbonyl iron powder to have a certain Flaky particles with aspect ratio, and b...

Embodiment 3

[0050] A preparation method of a graphene composite wave-absorbing material based on the full-band of future 5G mobile communication is as follows:

[0051] First, preheat the raw material of carbonyl iron powder, preheat the raw material under the protection of argon at 100°C for 2 hours; mix 4.9g of carbonyl iron powder raw material and bearing steel balls according to the mass ratio of material ball 1:10 Put it into a ball mill jar, wherein the bearing steel balls are composed of small balls with a diameter of 6mm and a middle ball with a diameter of 8mm. The mass ratio of the small balls to the middle balls is 1:1. Add 0.1g graphene oxide, 0.1g Calcium stearate, and add 50mL of absolute ethanol to immerse the raw material, stir evenly with a glass rod, and then seal it into a pendulum ball mill for ball milling. The ball milling time is 1 hour. The ball milling changes the shape of the spherical carbonyl iron powder to have a certain Flaky particles with aspect ratio, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com