Nano-micelle tanning agent, preparation method of nano-micelle tanning agent, and application of nano-micelle tanning agent in tanning leather

A technology of nano-micelle and tanning agent, applied in cleaning tanned leather and traditional tanning leather, nano-micelle tanning agent loaded with metal ions and the field of preparation thereof, can solve the problems that restrict the sustainable development of the leather industry, tanning and tanning. The leather waste liquid contains and affects the quality of finished leather, so as to avoid excessive hexavalent chromium content in finished leather, efficient utilization and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A preparation method of chromium-loaded nano micellar tanning agent is synthesized according to the following steps:

[0075] Step 1: Synthesis of Copolymer

[0076] (1) Synthesis of PEG-co-AA

[0077] A) Take methoxypolyethylene glycol acrylate monomer and acrylic acid monomer and dissolve them in ethanol at a molar ratio of 1:0.5, and add azobisisobutyronitrile with 0.5% of the total mass of the monomers into the above solution; After evacuating the oxygen with a water pump for 20 minutes, react at 70°C for 24 hours;

[0078] B) After the reaction, the reaction solution was concentrated by rotary evaporation, then precipitated in glacial ether for 2-3 times, and the PEG-co-AA binary copolymer was obtained after removing the ether;

[0079] (2) Synthesis of PEG-co-AA-co-GMA

[0080] A) Take methoxypolyethylene glycol acrylate monomer, acrylic acid monomer, glycidyl methacrylate, the monomer molar ratio is 1:1:0.5, dissolve the monomer in ethanol, weigh the monomer ...

Embodiment 2

[0088] Prepare zirconium-loaded nanomicelle type I, type II and type III tanning agents according to the method of Example 1, wherein the molar ratio of the two monomers of PEG-co-AA is 1:5, and PEG-co-AA-co-GMA The molar ratio of the three monomers of PEG-co-AA-co-SSEM is 1:0.5:2, the amount of initiator azobisisobutyronitrile in the polymerization reaction is 1.5% of the total mass of the monomers, and the inorganic metal ion for Zr 4+ ion, Zr 4+ The molar ratio of ions to carboxyl groups of the copolymer is 3:1, and finally, type I, type II and type III tanning agents of zirconium-loaded nanomicelles are obtained.

Embodiment 3

[0090] Prepare aluminum-loaded nanomicelle type I, type II and type III tanning agents according to the method of Example 1, wherein the molar ratio of the two monomers of PEG-co-AA is 1:2, and PEG-co-AA-co-GMA The molar ratio of the three monomers of PEG-co-AA-co-SSEM is 1:5:0.2, the amount of initiator azobisisobutyronitrile in the polymerization reaction is 1.2% of the total mass of the monomer, and the inorganic metal ion is al 3+ ion, Al 3+ The molar ratio of ions to carboxyl groups of the copolymer is 2:1, and the aluminum-loaded nanomicelle type I, type II and type III tanning agents are finally obtained.

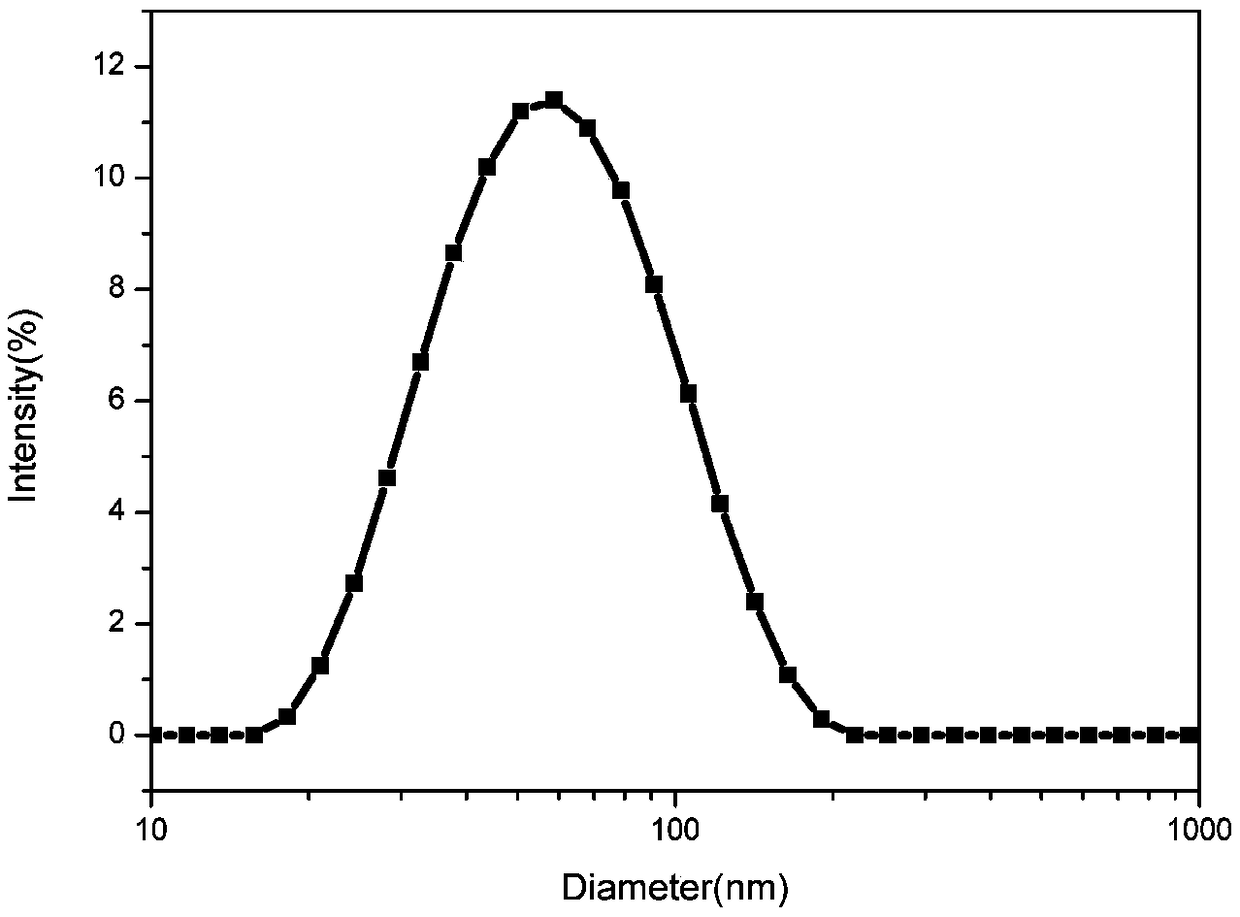

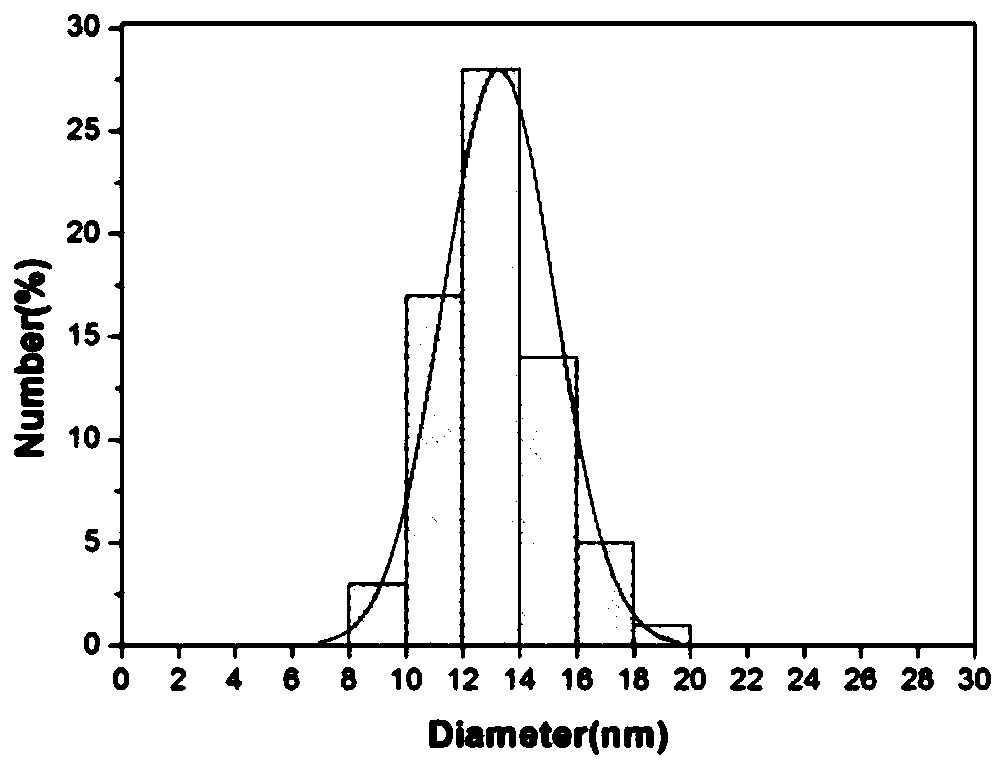

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com