Biomass utilization device and method based on coal-fired boiler high-temperature flue gas

A technology for high-temperature flue gas and coal-fired boilers, which is applied in the direction of combustion methods, biofuels, and the use of multiple fuels, which can solve the problems of large total investment, high initial investment and operating costs, and high operating risks, and achieve cost reduction and risks, high energy efficiency, and the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] S1: The high-temperature flue gas extracted from the coal-fired boiler system 100 is mixed and the temperature reaches 500-800°C, and is sent to the lower part of the biomass carbonization system 200 through the high-temperature flue gas inlet;

[0035] S2: sending the biomass material into the biomass dry distillation system 200 from the biomass inlet at the top of the biomass dry distillation reactor 6;

[0036] S3: In the high-temperature and low-oxygen environment of the biomass carbonization system 200, the biomass material is heated and dry-distilled by high-temperature flue gas to remove moisture, precipitate gas-phase substances and form a gas-phase mixture, and obtain carbonized carbon;

[0037] S4: The gas phase mixture precipitated in S3, including the flue gas after carbonization, the moisture and tar precipitated after biomass carbonization, and the temperature is higher than the boiling point of tar (380°C) and lower than the allowable temperature for the o...

Embodiment 2

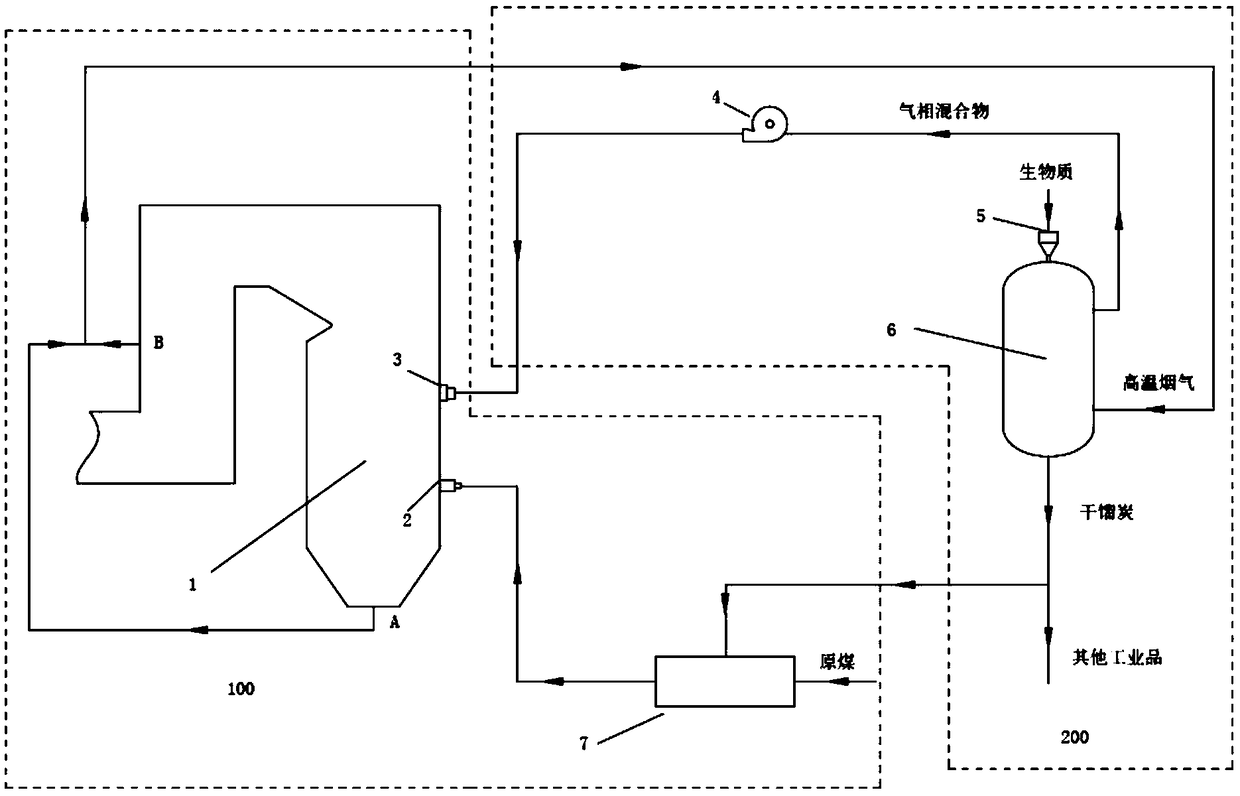

[0040] The present invention as figure 1 As shown, it includes a coal-fired boiler system 100 composed of a boiler fuel preparation device 7 and a furnace 1, a biomass carbonization system 200 composed of a biomass pretreatment feeding device 5 and a biomass carbonization reactor 6, and a furnace smoke fan 4 ; The coal-fired boiler system 100 is connected to the biomass carbonization system 200, and a furnace smoke blower 4 is arranged on the pipeline for transporting the gas phase mixture between them;

[0041] The boiler fuel preparation device 7 adopts a coal feeder and a coal mill. According to the difference in the form of the furnace 1, a belt-type or chain-type pulverizing system can be used; the furnace 1 is provided with high-temperature flue gas at different positions. At the extraction point, a pulverized coal burner 2 is also provided on the side wall connected to the boiler fuel preparation device 7, and a carbonization gas burner 3 is also provided on the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com