Method for reducing electrochemical degradation of proton exchange membrane

A proton exchange membrane, electrochemical technology, used in electrochemical generators, circuits, fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

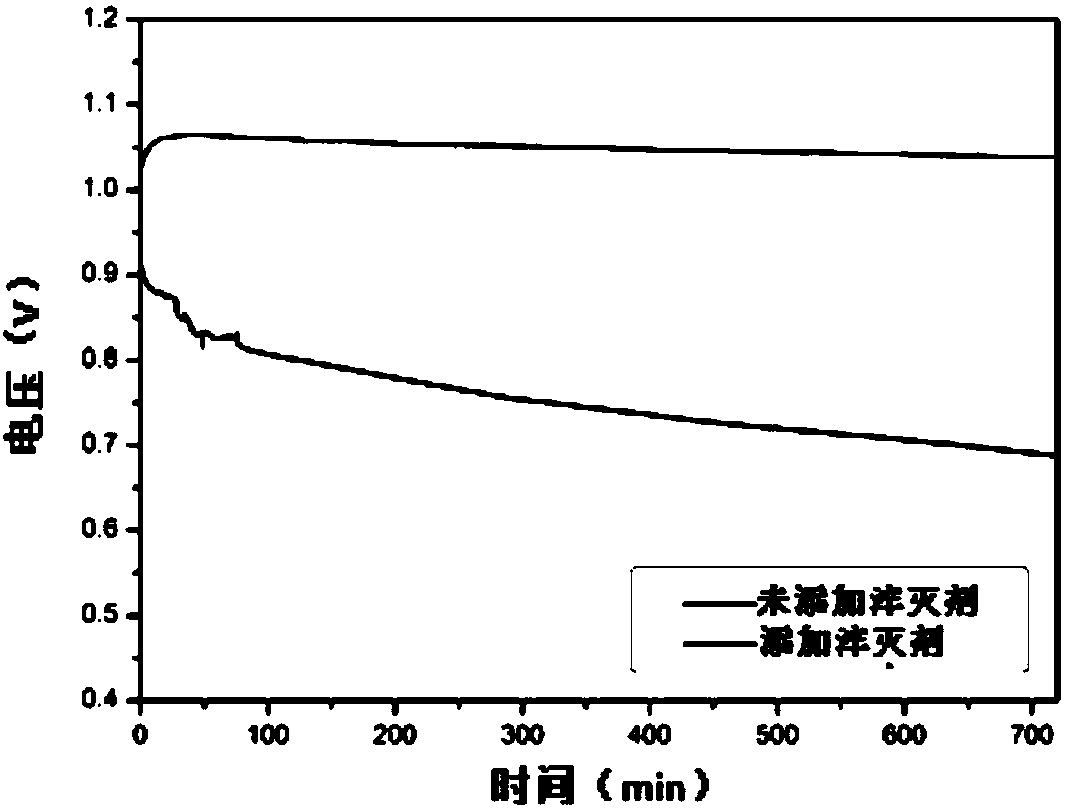

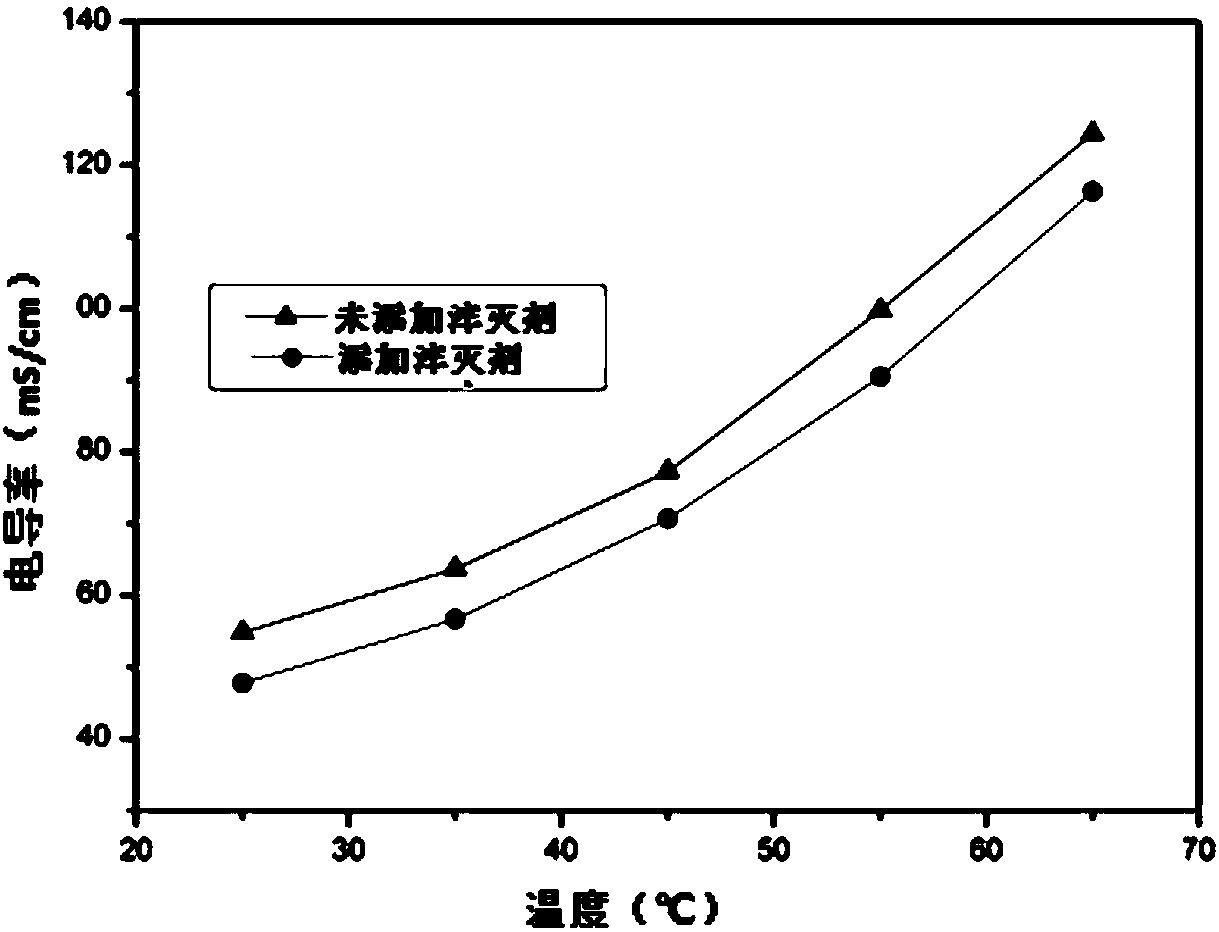

[0027] Part of the solvent of the 5wt% Nafion solution was evaporated to prepare a 20wt% Nafion solution. Dissolve 1g of SPEEK in 3g of dimethylacetamide, add 1.25g of 20wt% Nafion solution, and stir until completely dissolved at room temperature to make a SPEEK / Nafion solution (mass ratio SPEEK:Nafion=4:1). Take a certain amount of SPEEK / Nafion solution, and then add CeO with a final mass fraction of 0.5wt% 2 powder, where CeO 2 The average particle size is 14 nanometers, mixing and stirring for 2 hours, ultrasonication for 1 hour, and standing at room temperature for 5 hours to remove air bubbles, so as to avoid defects in the film formation process and prepare CeO 2 / Casting solution of ion exchange resin. Put the prepared casting solution on a horizontal glass plate with a size of 9×11 cm, and dry it in a drying oven at 80°C for 24 hours.

[0028] Using the same method as above, the difference is that the free radical quencher CeO is not added 2 , to prepare PEM witho...

Embodiment 2

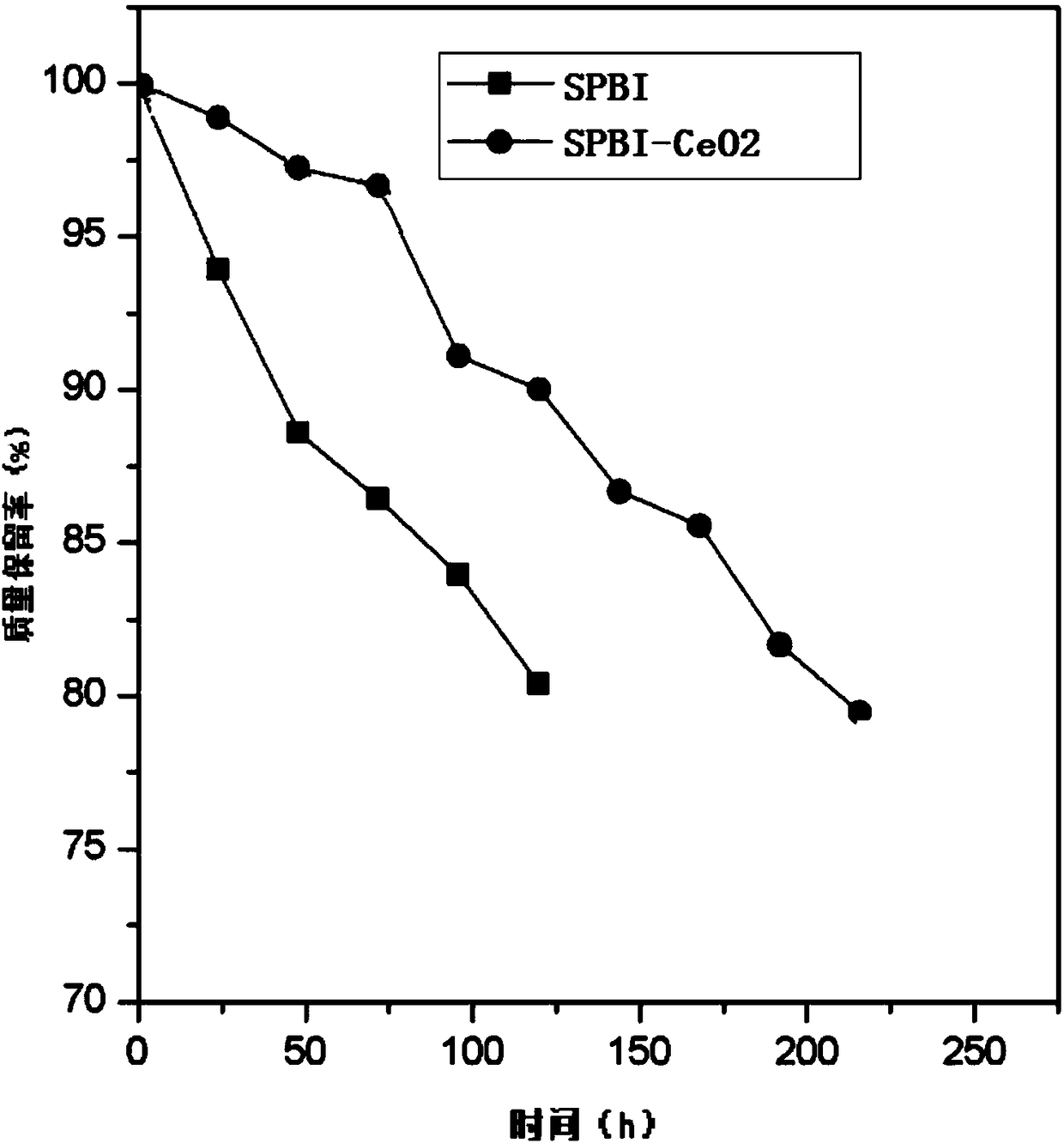

[0030] Preparation of casting solution slurry: Weigh 0.2244g of dry SPBI resin and dissolve it in 18g of N-methylpyrrolidone (NMP) solvent, stir until SPBI is completely dissolved, and filter to remove impurities. Then add mass fraction 2wt% CeO 2 powder, where CeO 2 The average particle size of the nanoparticles is 7 nanometers, mixing and stirring for 2 hours, ultrasonication for 1 hour, and standing at room temperature for 5 hours to remove air bubbles to obtain SPBI-CeO 2 Casting solution. Cast the casting solution onto a horizontal glass plate with a size of 9×11 cm, and dry it in a drying oven at 100°C for 24 hours. Get CeO 2 The loading is 2wt% SPBI-CeO 2 Composite film.

[0031] Using the same method as above, the difference is that the free radical quencher CeO is not added 2 , to prepare a proton exchange membrane without adding a free radical quencher——SPBI. The two prepared films were tested for their antioxidant properties in Fenton's reagent, such as ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com