Ink-jet printing method for micro-structure of quantum dot light guide plate mesh

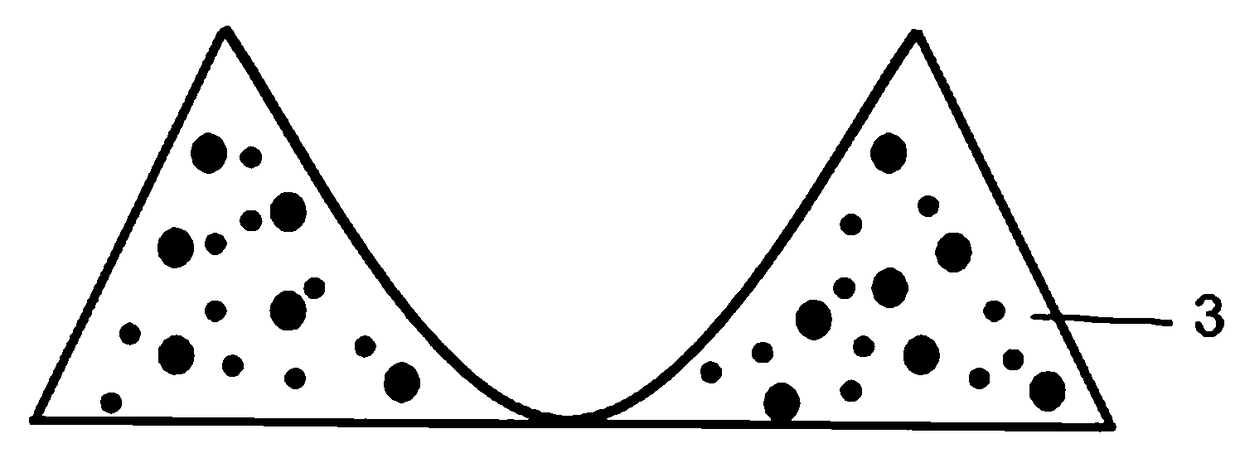

A light guide plate dot and inkjet printing technology, which is applied in the field of microcircuits, can solve the problems of affecting the light output effect of the device, increasing the difficulty of printing, and poor controllability of droplet size, so as to prevent dot collapse and dot bottom size from being too large, and reduce circulation The effect of printing times and saving printing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Taking specific production as an example, the production process has the following steps in sequence;

[0057] Step 1. The material of the light guide plate used in this example is polymethyl methacrylate (PMMA), its specific gravity is 1.20, the refractive index is 1.49, and the light transmittance is 92%;

[0058] Specifically, the thickness of the light guide plate is 1.5-3mm, and the size is 70mm*120mm;

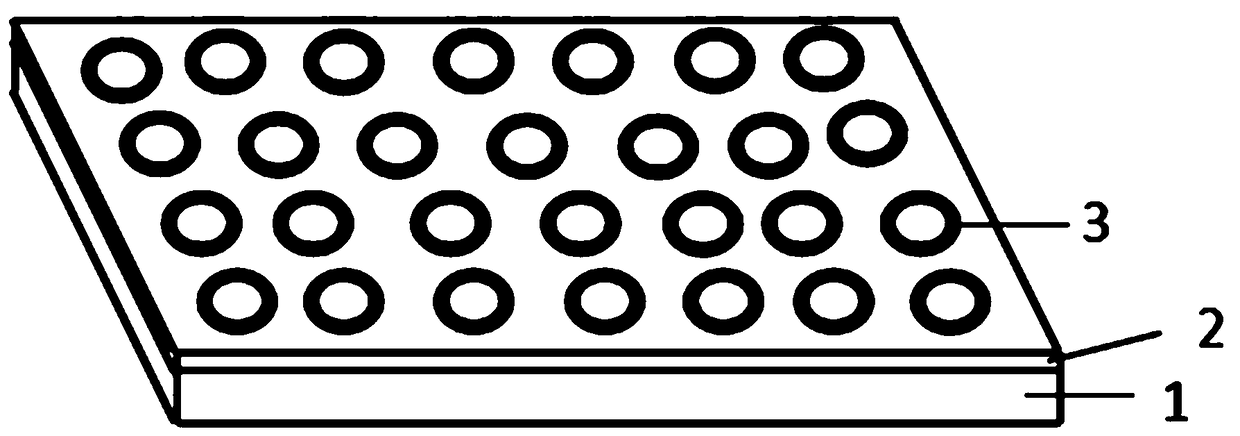

[0059] Step 2. In order to deposit ink droplets on the light guide substrate 1 to form standard spherical crown scattering dots, the light guide substrate 1 is pretreated;

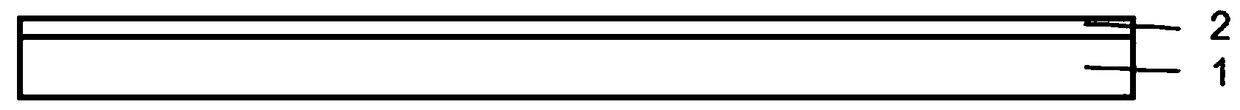

[0060] Specifically, scrape-coat PMMA solution on the light guide substrate 1, and dry it at room temperature for 24 hours to form a PMMA film 2 with a thickness of 80-100 nm;

[0061] Specifically, the concentration of used PMMA solution is 30mg / ml-50mg / ml, and used solvent is one or more in low polarity organic solvents such as toluene, chlorobenzene, chloroform, but not limited to these; D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com