Weather-resistant anti-flaming food package bag

A weather-resistant, packaging bag technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of reducing the practicability of packaging materials, bacterial growth on food surfaces, hard and brittle packaging bags, etc., to achieve good packaging and storage Effect, good packaging and protection function, effect of inhibiting high temperature melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

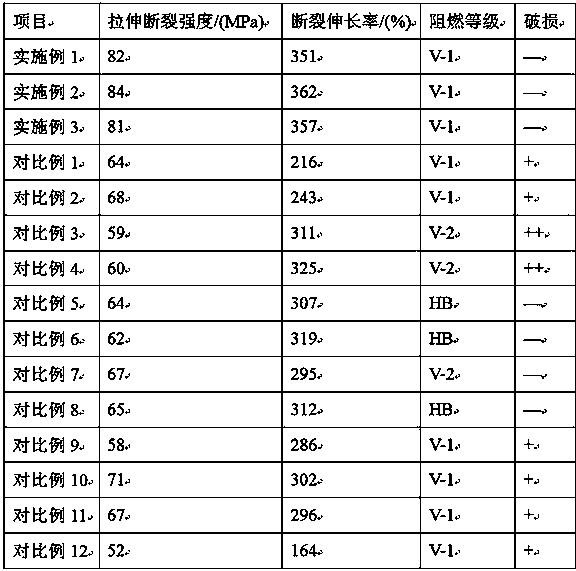

Examples

Embodiment 1

[0017] A weather-resistant flame-retardant food packaging bag, which is composed of the following raw materials in parts by weight: natural latex 36, modified polyurethane resin 23, ceramic fiber 11, copper ion fiber 11, nano-zeolite 7, nano-titanium dioxide 2.2, negative ion powder 0.5, five Antimony oxide 0.5.

[0018] For the modified polyurethane resin, the polyurethane resin is slowly heated to 120° C., fully melted, and sodium selenite solution is added, stirred evenly, kept for 30 minutes, and cooled to room temperature at a rate of 2° C. / min, which can improve the performance of the polyurethane resin. Strength and flexibility, increase the load-bearing capacity of the packaging bag, and pulverize to obtain modified polyurethane resin.

[0019] A method for preparing a weather-resistant flame-retardant food packaging bag, comprising the following steps:

[0020] (1) Put the ceramic fiber in an acetic acid solution with a volume fraction of 2%, heat it to 70°C, add nan...

Embodiment 2

[0026] A weather-resistant flame-retardant food packaging bag, which is composed of the following raw materials in parts by weight: natural latex 37, modified polyurethane resin 24, ceramic fiber 12, copper ion fiber 12, nano-zeolite 8, nano-titanium dioxide 2.3, anion powder 0.6, five Antimony oxide 0.6.

[0027] For the modified polyurethane resin, the polyurethane resin is slowly heated to 125° C., fully melted, added with sodium selenite solution, stirred evenly, kept for 35 minutes, and lowered to room temperature at a rate of 2.5° C. / min, which can improve the performance of the polyurethane resin. Strength and flexibility, increase the load-bearing capacity of the packaging bag, and pulverize to obtain modified polyurethane resin.

[0028] A method for preparing a weather-resistant flame-retardant food packaging bag, comprising the following steps:

[0029] (1) Put the ceramic fiber in 2.5% acetic acid solution by volume, heat it to 75°C, add nano-titanium dioxide, kee...

Embodiment 3

[0035] A weather-resistant flame-retardant food packaging bag, which is composed of the following raw materials in parts by weight: natural latex 38, modified polyurethane resin 25, ceramic fiber 13, copper ion fiber 13, nano-zeolite 9, nano-titanium dioxide 2.4, anion powder 0.7, five Antimony oxide 0.7.

[0036] For the modified polyurethane resin, slowly heat the polyurethane resin to 130°C, fully melt it, add sodium selenite solution, stir evenly, keep it warm for 40 minutes, and drop it to room temperature at a rate of 3°C / min, which can improve the performance of the polyurethane resin. Strength and flexibility, increase the load-bearing capacity of the packaging bag, and pulverize to obtain modified polyurethane resin.

[0037] A method for preparing a weather-resistant flame-retardant food packaging bag, comprising the following steps:

[0038] (1) Put the ceramic fiber in a 3% acetic acid solution, heat it to 80°C, add nano-titanium dioxide, keep it warm for 40 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com