Low-carbon steel component surface grinding technology

A surface grinding, low carbon steel technology, applied in the field of grinding, can solve the problems of low surface grinding quality, uneven grinding quality, damage to grinding equipment, etc., to increase the ability of grinding dirt, improve grinding efficiency, eliminate grinding dead end effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

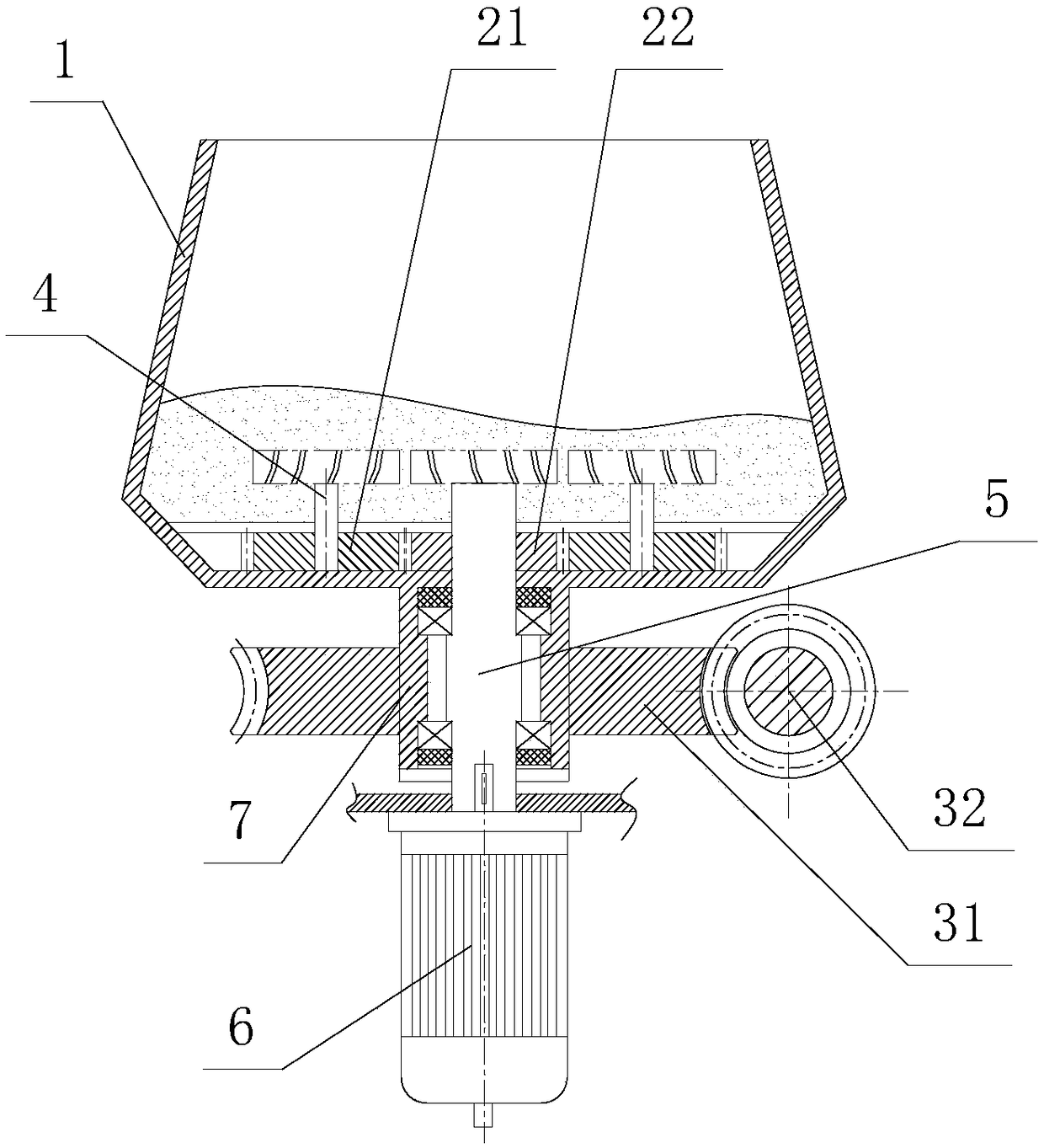

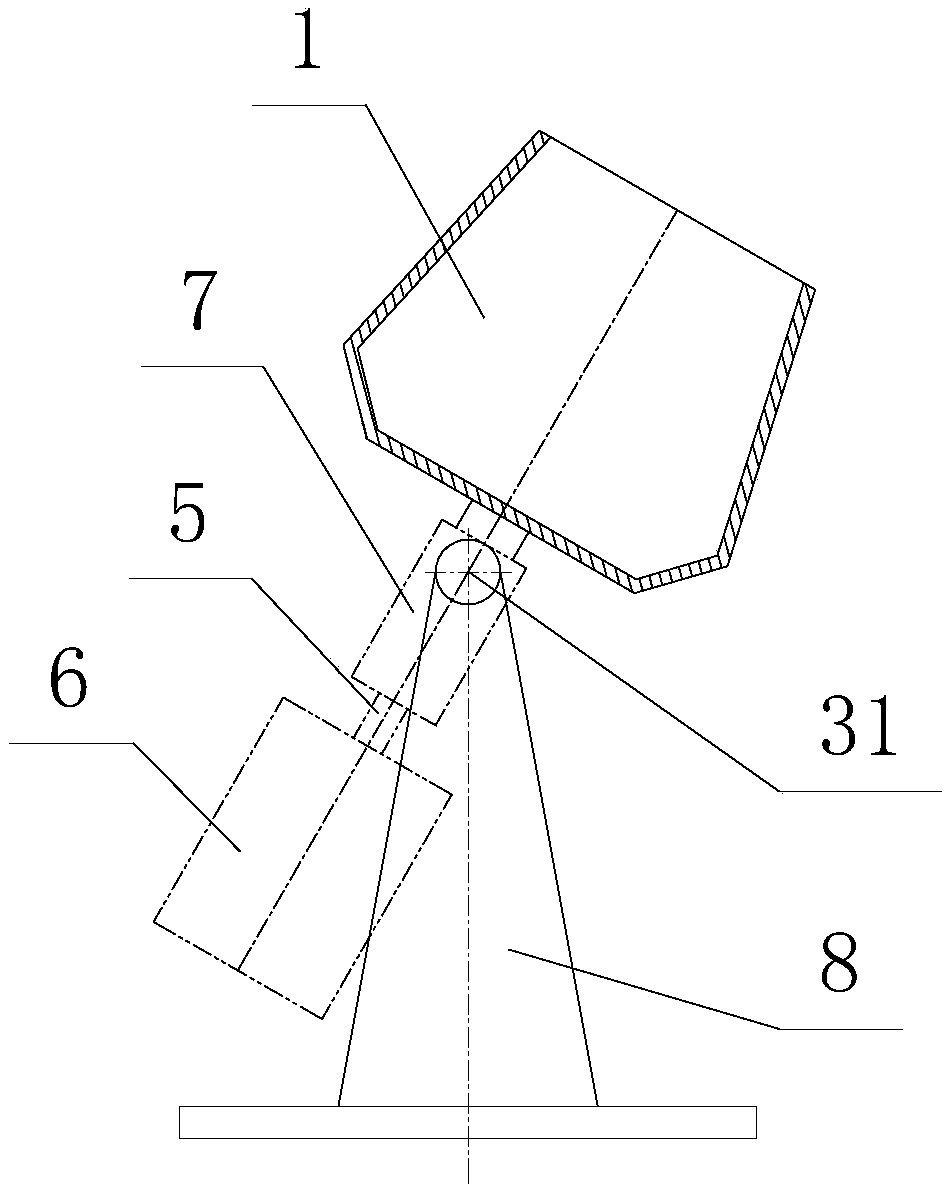

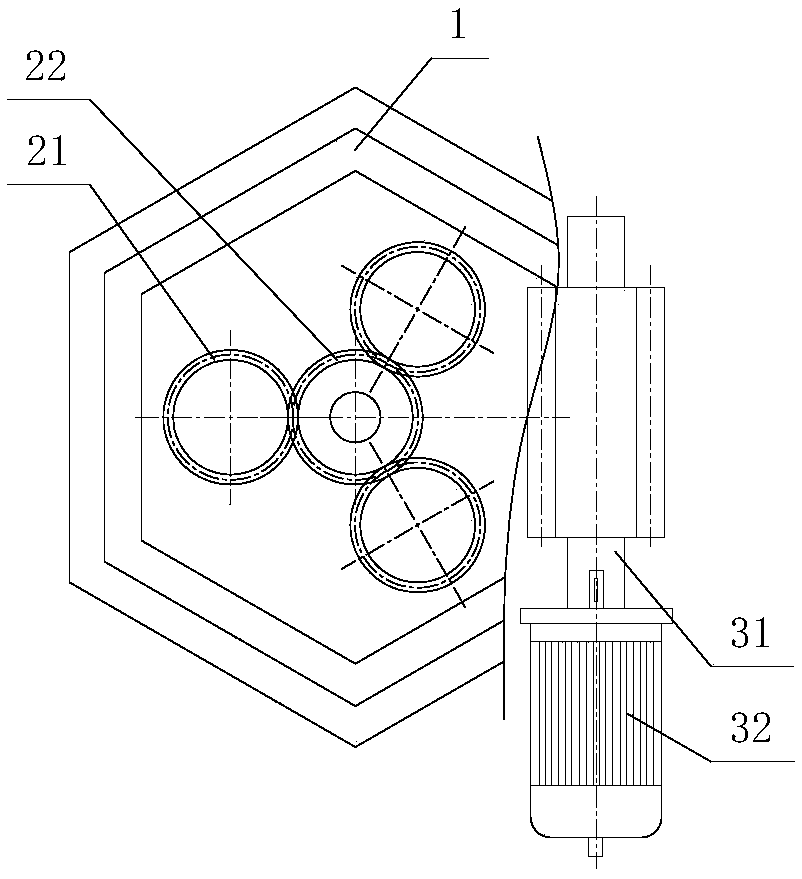

Method used

Image

Examples

Embodiment 1

[0024] The surface grinding process of the low carbon steel part provided by the present embodiment comprises the following steps:

[0025] (1) Preparation of grinding stone: 65 parts of silicon dioxide, 10 parts of aluminum oxide, 5 parts of titanium oxide, iron oxide (Fe 2 o 3 ) and 3 parts of mixed oxide, the mixed oxide is made by mixing 1 part of sodium oxide, 2 parts of potassium oxide and 1 part of magnesium oxide;

[0026] (2) preparation grinding agent: get coconut oil diethanolamide 20%, polyethylene 5%, sodium nitrite 3% and mixture 20% by weight percentage, surplus is Ro water, and described mixture is made of 5 parts of fatty acid, cocoa 8 10 parts mixed with potassium salt;

[0027] (3) Grinding: Fix the parts to be processed in the grinding device, add grinding stones accounting for 60% of the volume of the grinding chamber and abrasives accounting for 1‰ of the volume of the grinding chamber for grinding, and add Ro water or soft water depending on the volume...

Embodiment 2

[0030] The surface grinding process of the low carbon steel part provided by the present embodiment comprises the following steps:

[0031] (1) Preparation of grinding stone: take 70 parts of silicon dioxide, 15 parts of aluminum oxide, 8 parts of titanium oxide, 0.5 part of calcium oxide, iron oxide (Fe 2 o 3 ) 3.5 parts and 5 parts of mixed oxide, the mixed oxide is made by mixing 2 parts of sodium oxide, 1 part of potassium oxide and 1 part of magnesium oxide;

[0032] (2) preparation grinding agent: get coconut oil diethanolamide 25%, polyethylene 8%%, sodium nitrite 5% and mixture 25% by weight percentage, surplus is Ro water, and described mixture is made of 7 parts of fatty acid, cocoa 5 parts mixed with 10 parts potassium salt;

[0033] (3) Grinding: Fix the parts to be processed in the grinding device, add grinding stones accounting for 65% of the volume of the grinding chamber and abrasives accounting for 2‰ of the volume of the grinding chamber for grinding, and a...

Embodiment 3

[0036] The surface grinding process of the low carbon steel part provided by the present embodiment comprises the following steps:

[0037] (1) Preparation of grinding stone: take 75 parts of silicon dioxide, 20 parts of aluminum oxide, 10 parts of titanium oxide, 1 part of calcium oxide, iron oxide (Fe 2 o 3 ) and 7 parts of mixed oxide, the mixed oxide is made by mixing 1 part of sodium oxide, 1 part of potassium oxide and 3 parts of magnesium oxide;

[0038] (2) preparation grinding agent: get coconut oil diethanolamide 30%, polyethylene 10%, sodium nitrite 8% and mixture 30% by weight percentage, surplus is Ro water, and described mixture is made of 5 parts of fatty acid, cocoa 5 15 parts mixed with potassium salt;

[0039] (3) Grinding: Fix the parts to be processed in the grinding device, add grinding stones accounting for 70% of the volume of the grinding chamber and abrasives accounting for 5‰ of the volume of the grinding chamber for grinding, and add Ro water or so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com