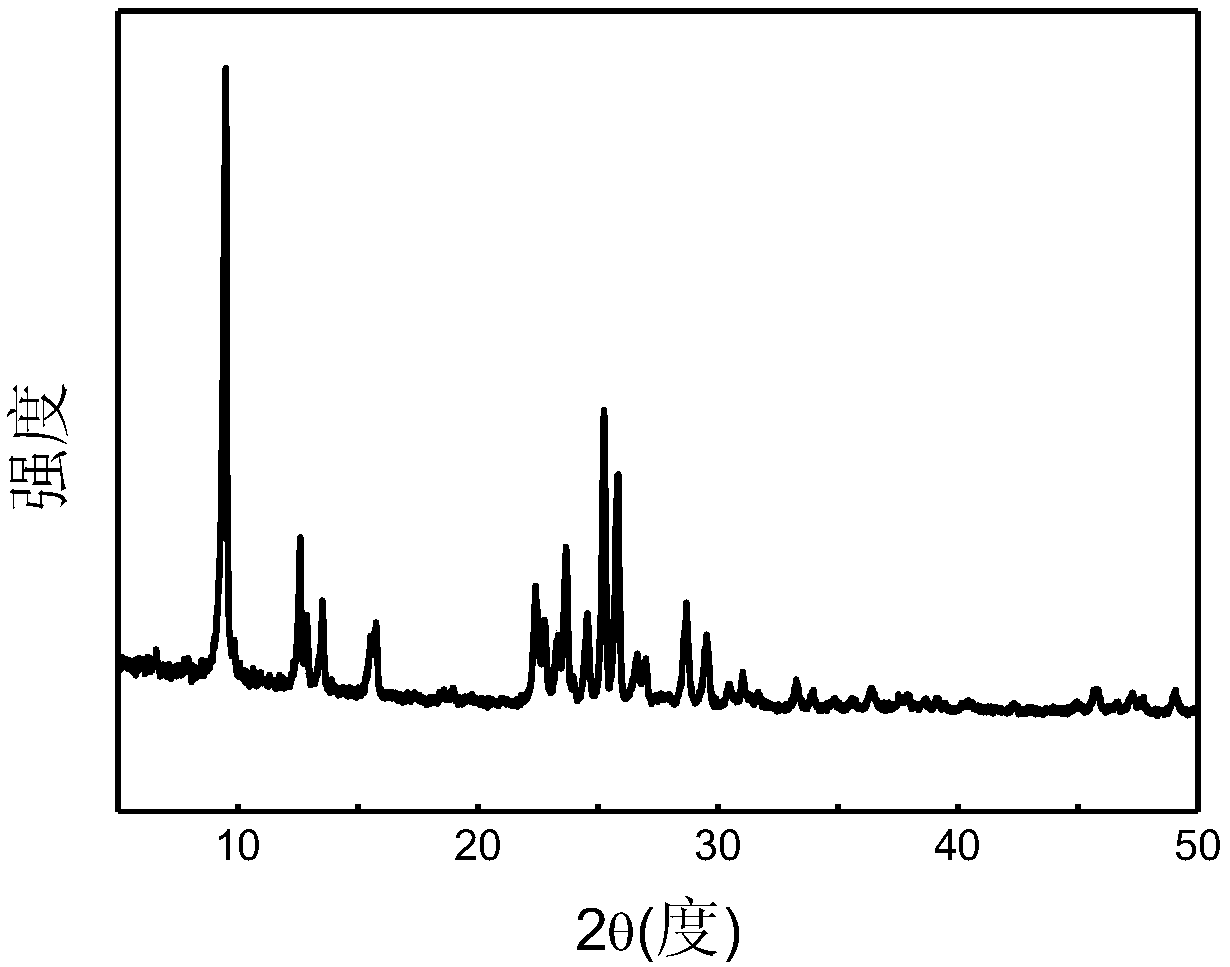

ZSM-35 molecular sieve and preparation method thereof

A technology of ZSM-35 and molecular sieves, which is applied in the field of preparation of molecular sieve catalysts, can solve problems such as ZSM-35 molecular sieves that have not been seen and have not yet been synthesized, so as to facilitate diffusion and mass transfer, improve conversion efficiency and isomerization selectivity, The effect of green environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Dissolve 1.415g of potassium hydroxide with a purity of 95wt.% in 20g of deionized water, stir evenly, add 1.23g of sodium metaaluminate with a purity of 80wt.%, stir until clear and transparent, and at the same time, dissolve with 10g of deionized water 2.088g of dipotassium hydrogen phosphate with a purity of 95wt.% was added dropwise to the above-mentioned clear and transparent solution, continued to stir for 15min, and then 24g of 30wt.% (as SiO 2 Calculate, the same below) silica sol, add a small amount of deionized water after the silica sol is added dropwise, and stir vigorously for 30 minutes to obtain the reactant gel. The molar ratio of each component in the reactant gel is about: 1.5Na 2 O: 4K 2 O: 20SiO 2 : 1Al 2 o 3 : 2HPO 4 2- : 600H 2 O.

[0085] Under the condition of stirring, the reactant gel is aged at about 25° C. for about 4 hours to prepare the reactant gel precursor.

[0086] The reactant gel precursor was transferred to a 100mL reaction ...

Embodiment 2

[0093] Dissolve 1.415g of potassium hydroxide with a purity of 95wt.% in 20g of deionized water, stir evenly, add 1.23g of sodium metaaluminate with a purity of 80wt.%, stir until clear and transparent, and at the same time, dissolve 1.044 g of dipotassium hydrogen phosphate with a purity of 95wt.% and 0.894g of potassium chloride with a purity of 98wt.% were added dropwise to the above-mentioned clear and transparent solution, stirred for 15 min, and then 24 g of a concentration of 30wt.% was added dropwise to the solution After the silica sol was added dropwise, a small amount of deionized water was added, and vigorously stirred for 30 minutes to obtain a reactant gel. The molar ratio of each component in the reactant gel is about: 1.5Na 2 O: 4K 2 O: 20SiO 2 : 1Al 2 o 3 : 1HPO 4 2- : 600H 2 O.

[0094] Under the condition of stirring, the reactant gel is aged at about 40° C. for about 2 hours to prepare the reactant gel precursor.

[0095] The reactant gel precursor...

Embodiment 3

[0100] Dissolve 0.825g of potassium hydroxide with a purity of 95wt.% in 20g of deionized water, stir evenly, add 0.718g of sodium metaaluminate with a purity of 80wt.%, stir until clear and transparent, at the same time, dissolve 1.218 g of dipotassium hydrogen phosphate with a purity of 95wt.%, was added dropwise to the above-mentioned clear and transparent solution, stirred for 15 min, and then 14 g of silica sol with a concentration of 30wt.% was added dropwise in the solution, and after the addition of the silica sol was completed, the A small amount of deionized water was added and vigorously stirred for 30 min to obtain a reactant gel. The molar ratio of each component in the reactant gel is about: 1.5Na 2 O: 4K 2 O: 20SiO 2 : 1Al 2 o 3 : 2HPO 4 2- : 1200H 2 O.

[0101]Under the condition of stirring, the reactant gel is aged at about 31-32° C. for about 3 hours to prepare the reactant gel precursor.

[0102] The reactant gel precursor was transferred to a 100m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com