Mixture for quickly repairing asphalt pavement and repairing method thereof

A technology of asphalt mixture and asphalt pavement, which is applied in the field of asphalt pavement repair, can solve the problems that it is not suitable for small area and emergency repair, the performance cannot be consistent with that of ordinary pavement, and the repair depth is deep, so as to shorten the construction period, improve the service life, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

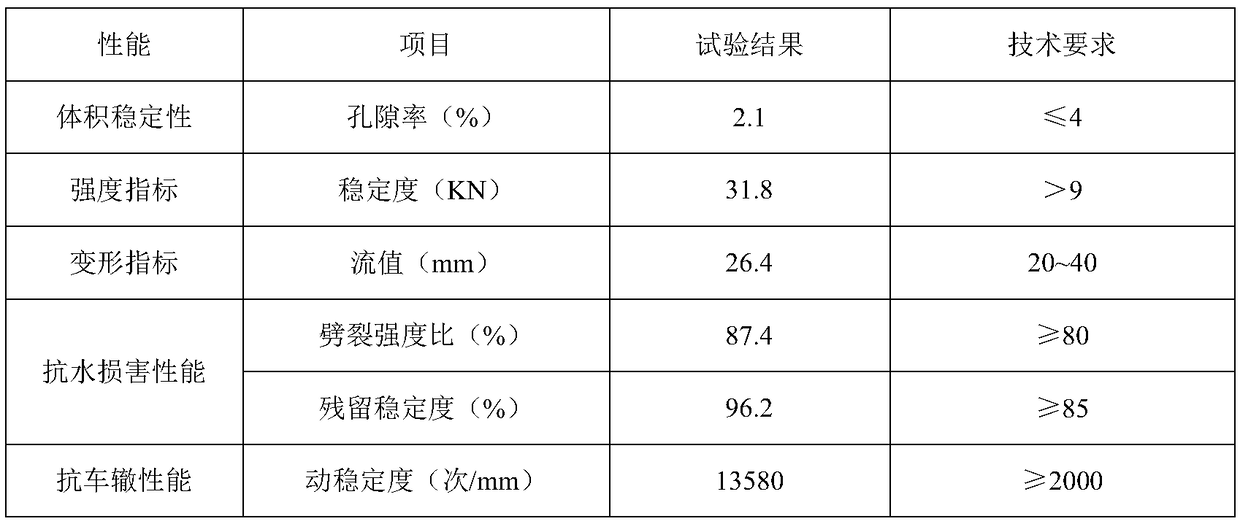

[0019] What this embodiment chooses is that the area is 1m 2 asphalt road with potholes. Among them, the bonding material is ordinary emulsified asphalt for ordinary roads, scrap steel slag and mineral powder are purchased from the market, and the water reducer is polycarboxylate water reducer and naphthalene water reducer with a mass ratio of 4:3:1. and sulfamate superplasticizers. The specific raw materials of cold mix asphalt mixture and grouting materials are shown in Table 1 to Table 3 below.

[0020] Table 1 Composition of cold mix asphalt mixture

[0021] raw material

Bio-based cold patch asphalt

mineral powder

content / %

3

93

4

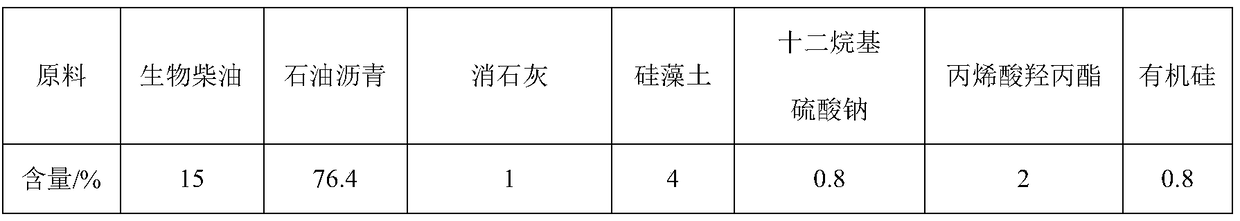

[0022] Table 2 Composition of bio-based cold patch asphalt

[0023]

[0024] Table 3 Grouting Material Composition

[0025] raw material

Quartz sand

rubber powder

content / %

50

35

0.3

0.5 ...

Embodiment 2

[0038] What this embodiment chooses is that the area is 1.5m 2 asphalt road with potholes. Among them, the bonding material is modified emulsified asphalt, scrap steel slag and mineral powder are purchased from the market, and the water reducer is polycarboxylate water reducer, naphthalene series water reducer and sulfamate with a mass ratio of 5:4:1 Water reducing agent. The specific raw materials of cold-mix asphalt mixture and grouting materials are shown in Table 5 to Table 7 below.

[0039] Table 5 Composition of cold mix asphalt mixture

[0040] raw material

Bio-based cold patch asphalt

Scrap slag

mineral powder

content / %

5

91

4

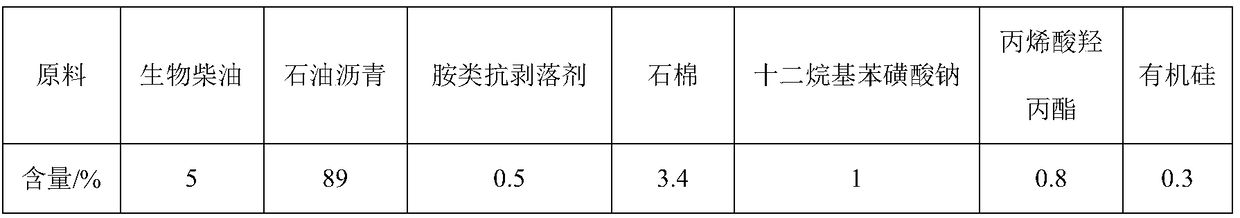

[0041] Table 6 Composition of bio-based cold patch asphalt

[0042]

[0043] Table 7 Grouting Material Composition

[0044] raw material

Quartz sand

rubber powder

content / %

40

40

0.1

0.7

19.2 ...

Embodiment 3

[0057]What this embodiment chooses is that the area is 2m 2 asphalt road with potholes. Among them, the bonding material is water-based epoxy asphalt, scrap steel slag and mineral powder are purchased from the market, and the water reducer is polycarboxylate water reducer, naphthalene-based water reducer and sulfamate with a mass ratio of 3:1:1 Water reducing agent. The specific raw materials of cold-mix asphalt mixture and grouting materials are shown in Table 9 to Table 11 below.

[0058] Table 9 Composition of cold mix asphalt mixture

[0059] raw material

Bio-based cold patch asphalt

Scrap slag

mineral powder

content / %

1

95

4

[0060] Table 10 Composition of bio-based cold patch asphalt

[0061] raw material

asphalt

Slaked lime

rock asphalt

Hydroxypropyl Acrylate

content / %

30

65

0.1

3.4

0.4

0.8

0.3

[0062] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com