Modified graphene oxide concrete crack repairing material and preparation method thereof

A technology for repairing cracks and oxidizing rocks, which is applied in the field of modified graphene oxide concrete crack repairing materials and its preparation, which can solve the problems of high cost and huge cost, and achieve the effects of preventing segregation, promoting fluidity, and simple production and repairing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing a modified graphene oxide concrete crack repair material, specifically a method for preparing a large-scale single-layer modified graphene oxide reinforced and toughened concrete crack repair material, comprising the following steps:

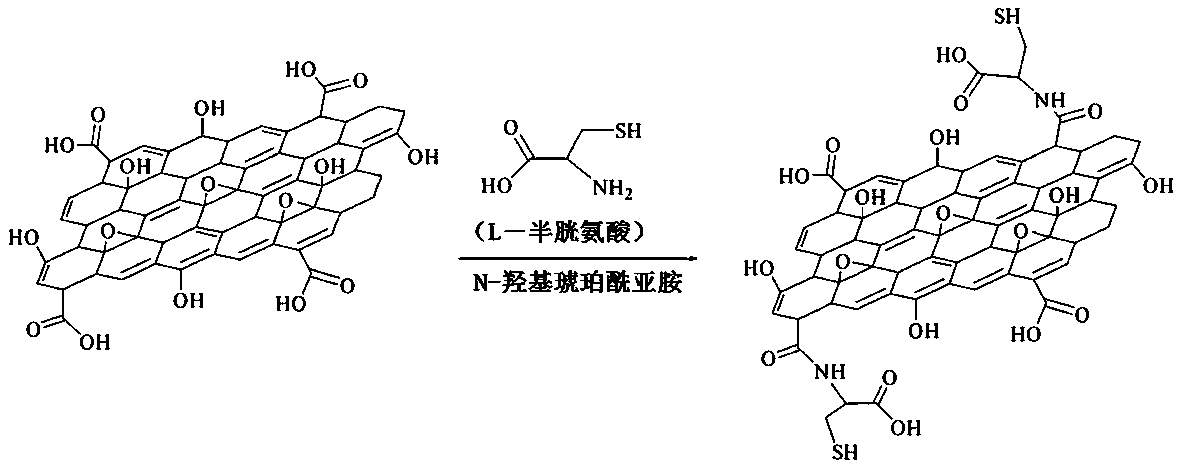

[0039] Step 1, prepare the modified graphene oxide dispersion with terminal mercapto groups, see the chemical reaction process figure 1 : Add 40 to 60 parts of graphene oxide dispersion liquid with a mass fraction of 2 to 2.5% into 90 to 100 parts of water and stir evenly, then add 0.1 to 0.3 parts of N-hydroxysuccinimide and 3.0 to 4.5 parts of L -Cysteine, feed nitrogen gas, stir and react at 25~30°C for 7~8 hours, centrifuge the product to obtain slurry modified graphene oxide with terminal sulfhydryl groups, use deionized water to disperse and control The mass fraction of the modified graphene oxide dispersion is 0.6%~0.8%;

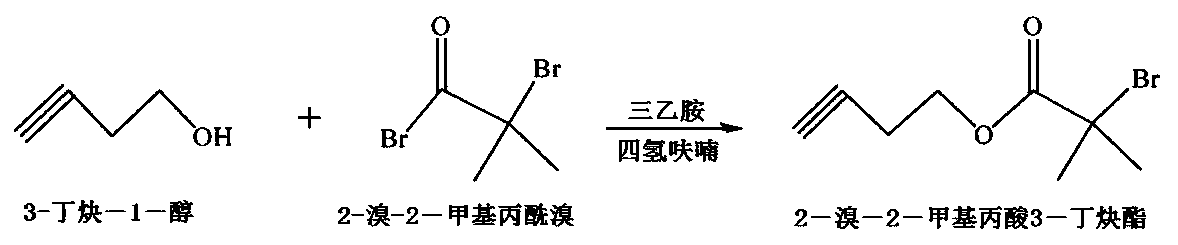

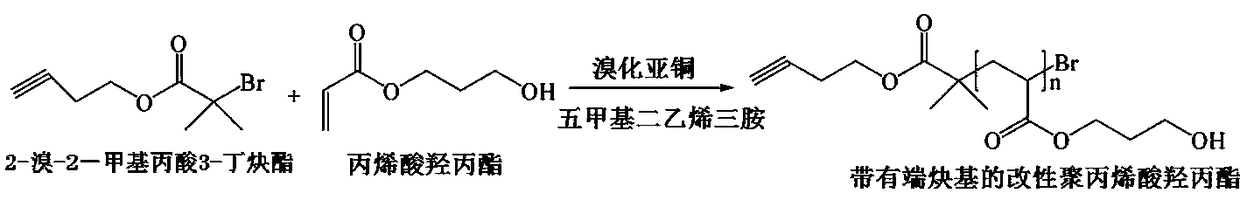

[0040] Step 2, prepare 3-butynyl 2-bromo-2-methylpropionate, se...

Embodiment 1

[0053] Prepare the modified graphene oxide concrete crack repair material, the preparation steps are as follows:

[0054] Step 1, prepare a modified graphene oxide dispersion with terminal mercapto groups:

[0055] Add 40 parts of graphene oxide dispersion liquid with a mass fraction of 2% to 90 parts of water and stir evenly, then add 0.1 part of N-hydroxysuccinimide and 3.0 parts of L-cysteine, feed nitrogen, and The reaction was stirred and reacted at ℃ for 7 hours, and the product was separated by centrifugation to obtain slurry-like modified graphene oxide with terminal mercapto groups. Deionized water was used to disperse and control the mass fraction of graphene oxide to 0.6%.

[0056] Step 2, prepare 3-butynyl 2-bromo-2-methylpropionate:

[0057] Add 10 parts of 3-butyn-1-ol, 60 parts of tetrahydrofuran and 8 parts of triethylamine into the reactor, blow nitrogen into it, and slowly add 6.4 parts of 2-bromo-2 -Methylpropionyl bromide, stirred for 10 hours, added 80 p...

Embodiment 2

[0077] Prepare the modified graphene oxide concrete crack repair material, the preparation steps are as follows:

[0078] Step 1, prepare a modified graphene oxide dispersion with terminal mercapto groups:

[0079] Add 60 parts of graphene oxide dispersion liquid with a mass fraction of 2.5% to 100 parts of water and stir evenly, then add 0.3 parts of N-hydroxysuccinimide and 4.5 parts of L-cysteine, pass into nitrogen, at 30 The reaction was stirred and reacted at ℃ for 8 hours, and the product was centrifuged to obtain a slurry-like modified graphene oxide with terminal mercapto groups. Deionized water was used to disperse and control the mass fraction of graphene oxide to 0.8%.

[0080] Step 2, prepare 3-butynyl 2-bromo-2-methylpropionate:

[0081] Add 15 parts of 3-butyn-1-ol, 80 parts of tetrahydrofuran and 12 parts of triethylamine into the reactor, blow nitrogen into it, and slowly add 7.4 parts of 2-bromo-2 -Methylpropionyl bromide, stirring and reacting for 15 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com