Preparation method and system of sterol ester

A preparation system and sterol ester technology are applied in the preparation of phytosterol esters and in the field of preparation of sterol esters, and can solve the problems of deep color, low purity and high acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

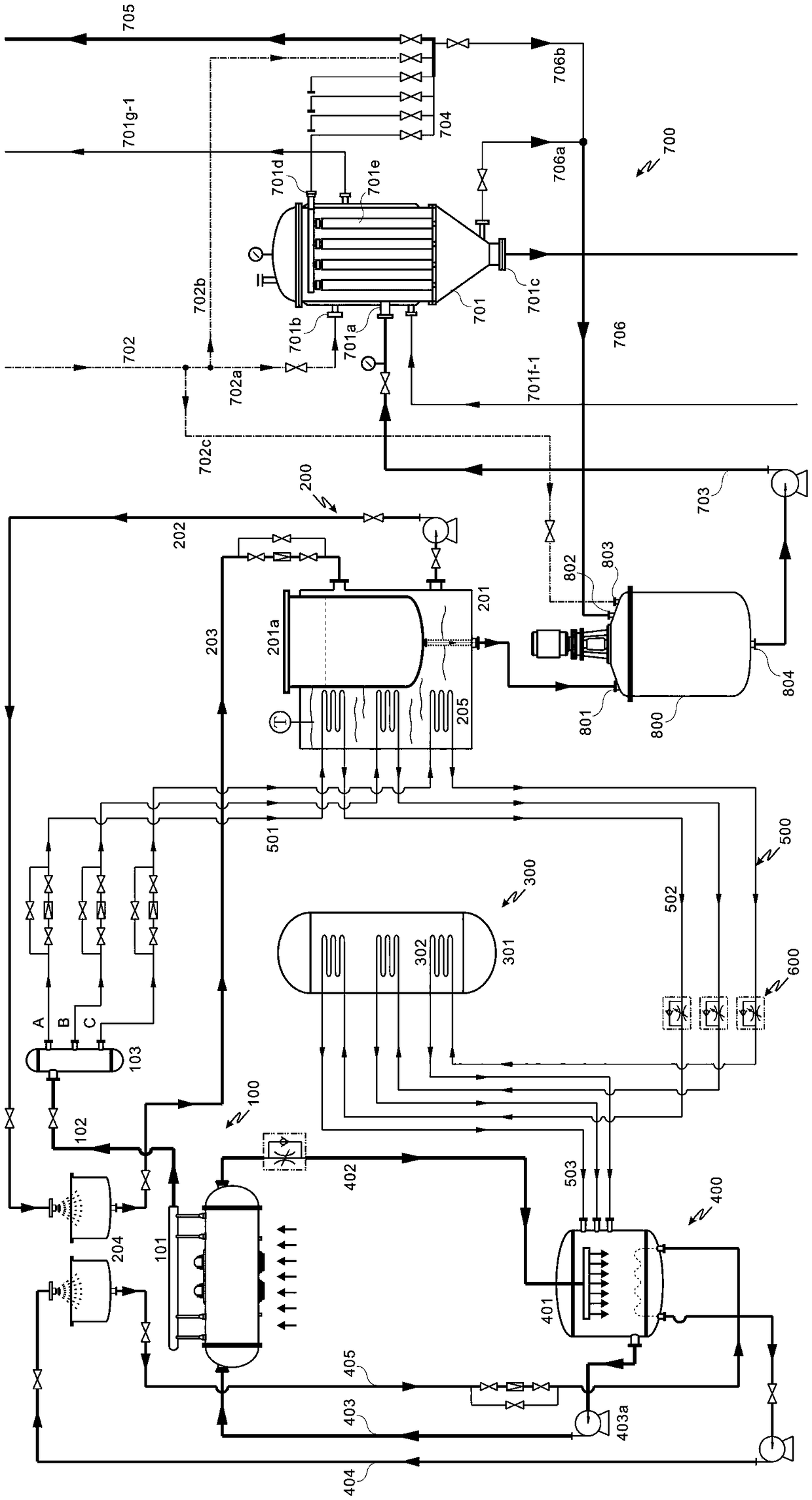

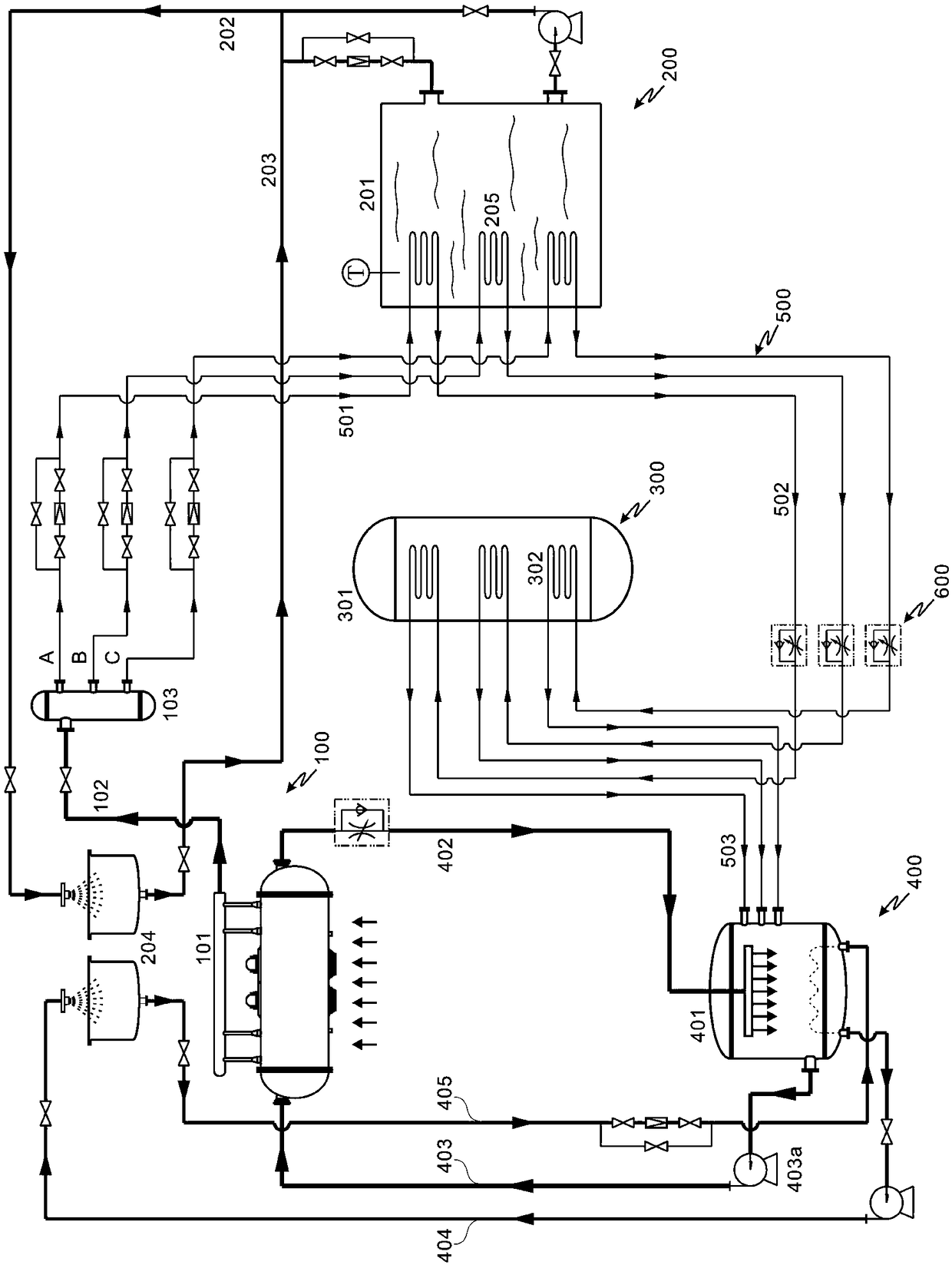

[0031] The deodorized distillate of corn oil and fatty acid methyl ester are placed in the heat conduction device 201a of the first heat exchange unit 200 at a mass ratio of 7:1 for mixing, so that they are completely dissolved at 85°C to obtain the first mixed solution;

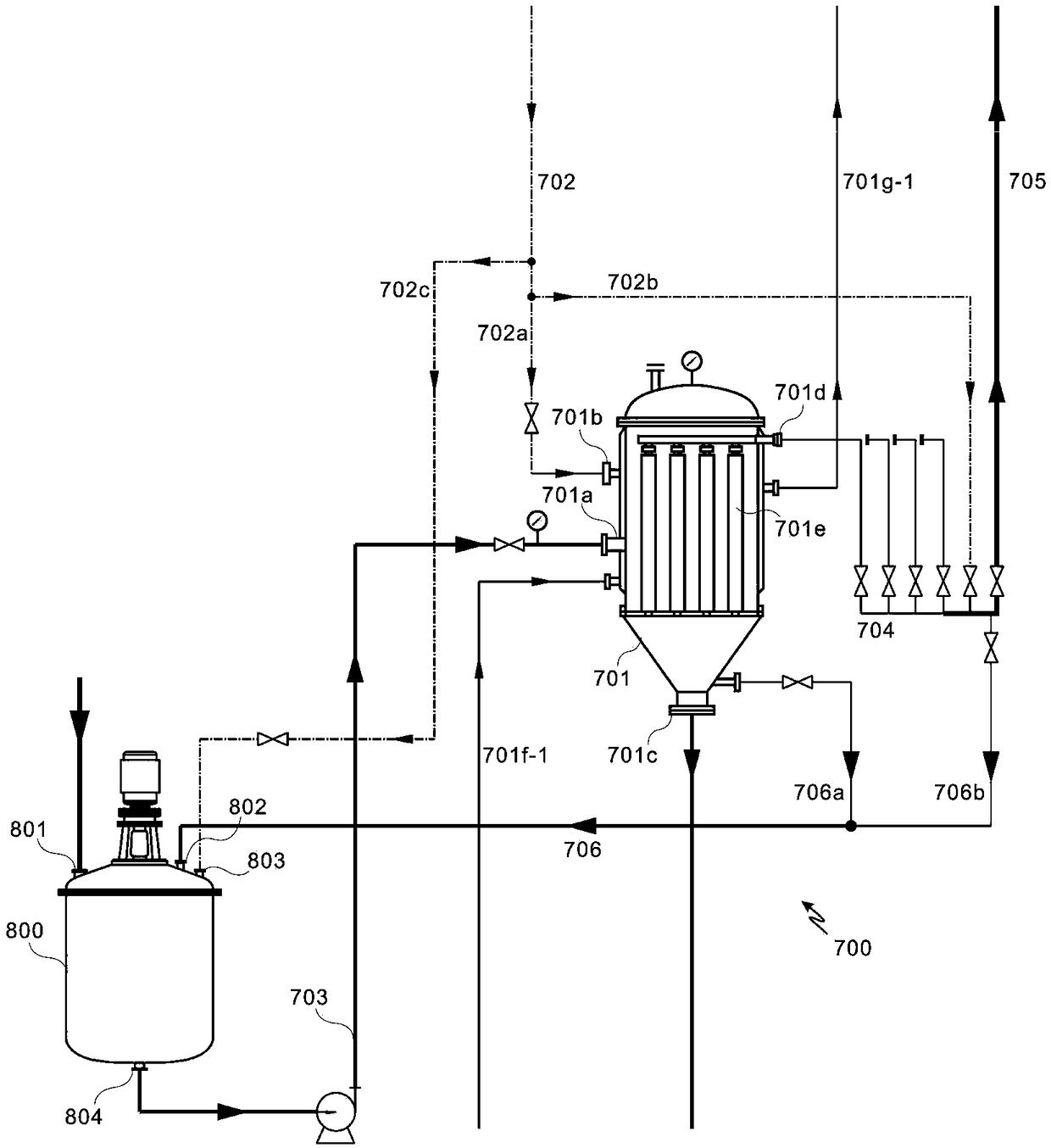

[0032] Transfer the first mixed liquid to the reaction unit 800, the reaction unit 800 can use a reaction kettle, and adjust the temperature value in its jacket, so that the first mixed liquid is gradually heated to 200 ° C, and vacuumized to obtain the second mixed liquid ;

[0033] Add sodium methoxide methanol solution with a mass fraction of 40% into the reaction unit 800. The amount of sodium methoxide added is 2% of the mass of the mixed solution, and the vacuum state is kept to continue the reaction for 4 hours. After the reaction, the mixed solution is cooled to 120° C. and kept at 1.5 hours, then cooled to 100°C;

[0034] Add pure water to the reacted material to fully wash, the washing liquid is d...

Embodiment 2

[0072] Mix corn oil deodorized distillate and fatty acid methyl ester at a mass ratio of 8:1, dissolve completely at 90°C, then heat up to 200°C, and vacuumize to obtain a mixed solution; add sodium methoxide methanol with a mass fraction of 50% solution, the amount of sodium methoxide added is 3% of the mass of the mixed solution, and the reaction is continued for 8 hours in a vacuum state. After the reaction, the mixed solution is cooled to 120° C. for 2 hours, and then cooled to 90° C. Add pure water to the reacted material to fully wash, the washing liquid is discharged into the waste water, and the oil layer is washed with water for many times until neutral. The washed material is vacuumed to remove moisture. Add activated clay to the washed and dehydrated material, stir at 80°C for about 60 minutes under vacuum, with a stirring speed of 200r / min, transfer to a filter to filter out the clay, and distill at 20Pa and 200°C to obtain the finished product of sterol ester . ...

Embodiment 3

[0077] Mix soybean oil deodorized distillate and fatty acid methyl ester at a mass ratio of 8:1, dissolve completely at 85°C, heat up to 180°C, and vacuumize to obtain a mixed solution; add 40% sodium methoxide methanol For the solution, the amount of sodium methoxide added is 2% of the mass of the mixed solution, and the reaction is continued for 6 hours in a vacuum state. After the reaction, the mixed solution is cooled to 115° C. for 2 hours, and then cooled to 110° C. Add pure water to the reacted material to fully wash, the washing liquid is discharged into the waste water, and the oil layer is washed with water for many times until neutral. The washed material is vacuumed to remove moisture. Add activated clay to the washed and dehydrated material, stir at 90°C for about 50 minutes under vacuum, and the stirring speed is 200r / min, transfer to a filter to filter out the clay, and distill at 50Pa and 210°C to obtain the finished product of sterol ester .

[0078] The col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com