Laminated aluminum alloy template and preparation method thereof

An aluminum alloy formwork and film-coating technology, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as concrete pollution, improper brushing thickness, and pitted concrete surfaces, so as to increase turnover times, reduce costs, and improve surface quality. Wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

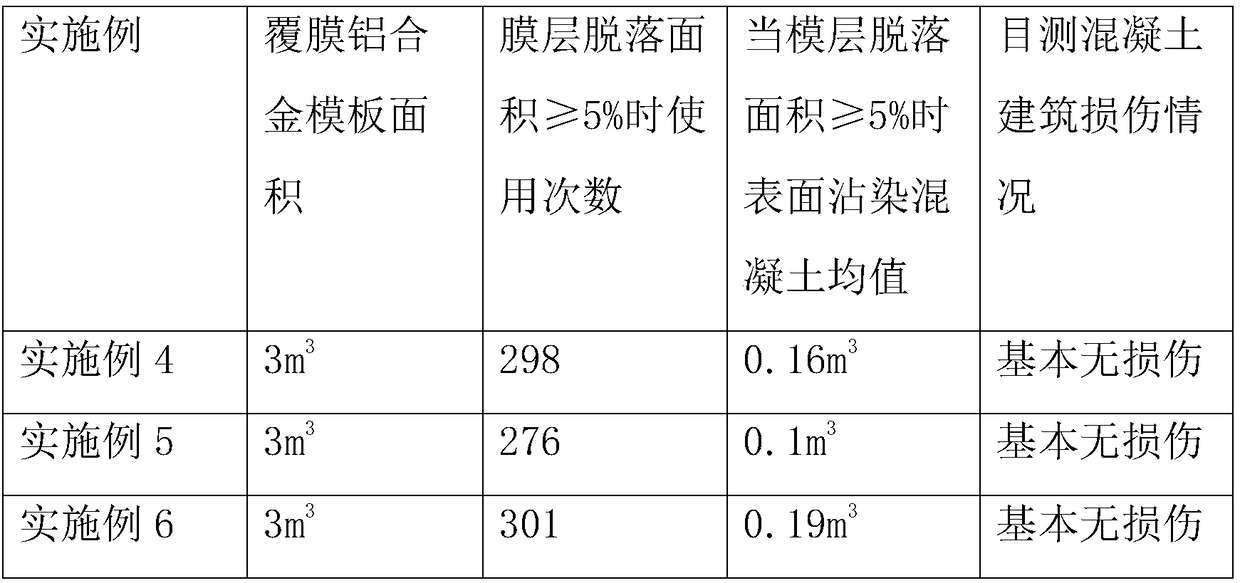

Examples

Embodiment 1

[0024] Example 1: Preparation of titanium-based / nickel-clad aluminum powder

[0025] 30 parts by weight of titanium dioxide powder, 15 parts by weight of nickel-coated aluminum powder, 5 parts by weight of ferric oxide powder, 10 parts by weight of silane coupling agent, titanium dioxide powder: nickel-coated aluminum powder: ferric oxide powder mass ratio=3:1.5 :0.5;

[0026] After mixing titanium dioxide powder, silane coupling agent and ferric oxide powder, perform vibratory grinding for 2 hours at a frequency of 2000r / min, add nickel-clad aluminum powder, stir evenly, perform high-temperature calcination at a high temperature of 800°C, and pass inert Gas, the flow rate is 4L / min, take it out after 20min, cool to 300°C, perform ultrasonic oscillation for 25min at a frequency of 20kHz, and obtain titanium-based / nickel-clad aluminum powder.

Embodiment 2

[0027] Example 2: Preparation of titanium-based / nickel-clad aluminum powder

[0028] 18 parts by weight of titanium dioxide powder, 12 parts by weight of nickel-coated aluminum powder, 3 parts by weight of ferric oxide powder, 10 parts by weight of silane coupling agent, titanium dioxide powder: nickel-coated aluminum powder: ferric oxide powder mass ratio=1.8:1.2 :0.3;

[0029] After mixing titanium dioxide powder, silane coupling agent and ferric oxide powder, perform vibratory grinding for 1.5 hours at a frequency of 2000r / min, add nickel-coated aluminum powder, stir evenly, perform high-temperature calcination at a high temperature of 900°C, and pass into Inert gas, the flow rate is 5L / min, take it out after 15min, cool to 250°C, perform ultrasonic oscillation for 30min at a frequency of 25kHz, and obtain titanium-based / nickel-clad aluminum powder.

Embodiment 3

[0030] Example 3: Preparation of titanium-based / nickel-coated aluminum powder three

[0031] 15 parts by weight of titanium dioxide powder, 10 parts by weight of nickel-coated aluminum powder, 1 part by weight of ferric oxide powder, 8 parts by weight of silane coupling agent, mass ratio of titanium dioxide powder: nickel-coated aluminum powder: ferric oxide powder=1.5:1 :0.1;

[0032] After mixing titanium dioxide powder, silane coupling agent and ferric oxide powder, perform vibratory grinding for 1 hour at a frequency of 1500r / min, add nickel-clad aluminum powder, stir evenly, perform high-temperature calcination at a high temperature of 1000°C, and pass inert Gas, the flow rate is 4L / min, take it out after 10min, cool to 200°C, perform ultrasonic oscillation for 20min at a frequency of 20kHz to obtain titanium-based / nickel-clad aluminum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com