Preparation of pd-sno2 nanocomposite and its application in hydrogen sensor

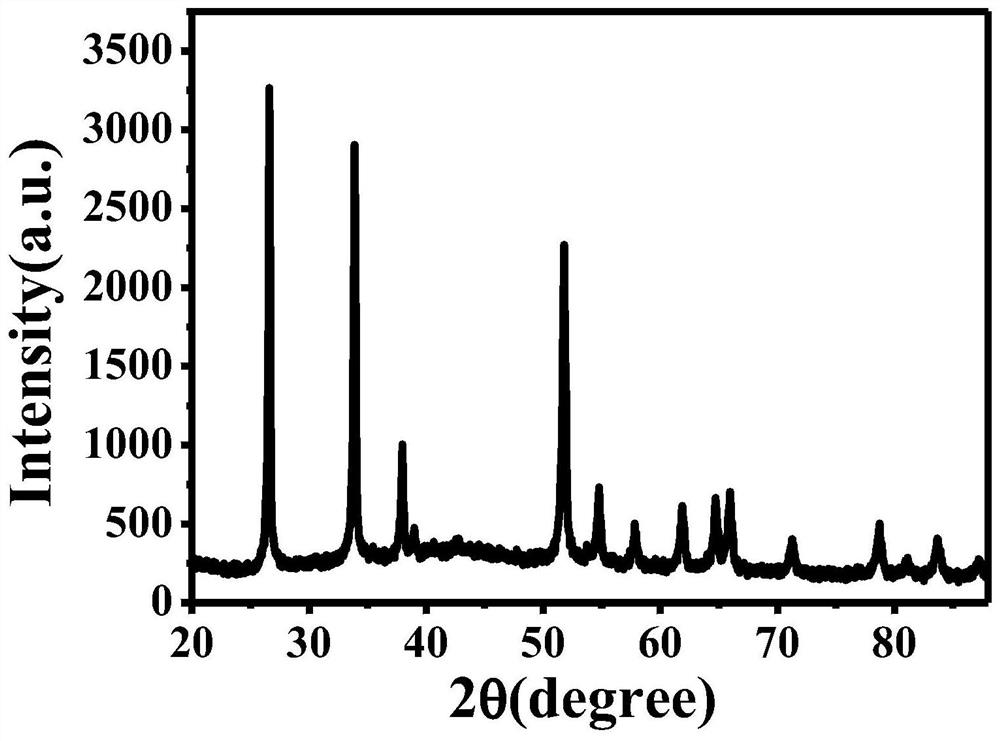

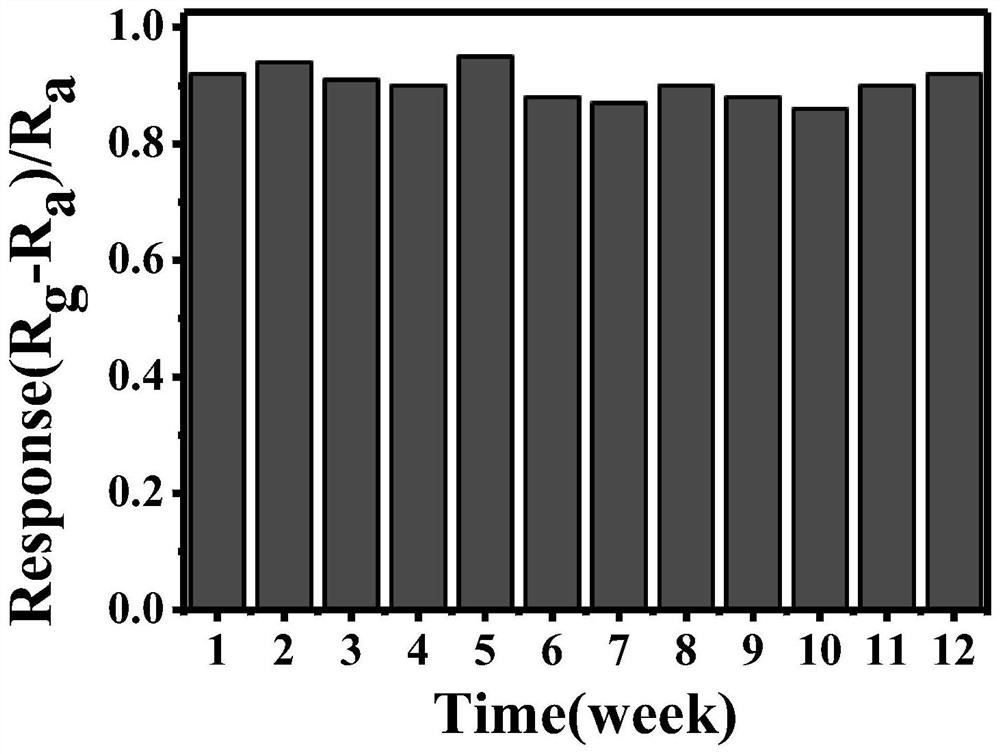

A nano-composite material, pd-sno2 technology, applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of limiting the scope of applications and places of use, poor selectivity, indistinguishable, etc. In adsorption and desorption, good crystallinity, and the effect of preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

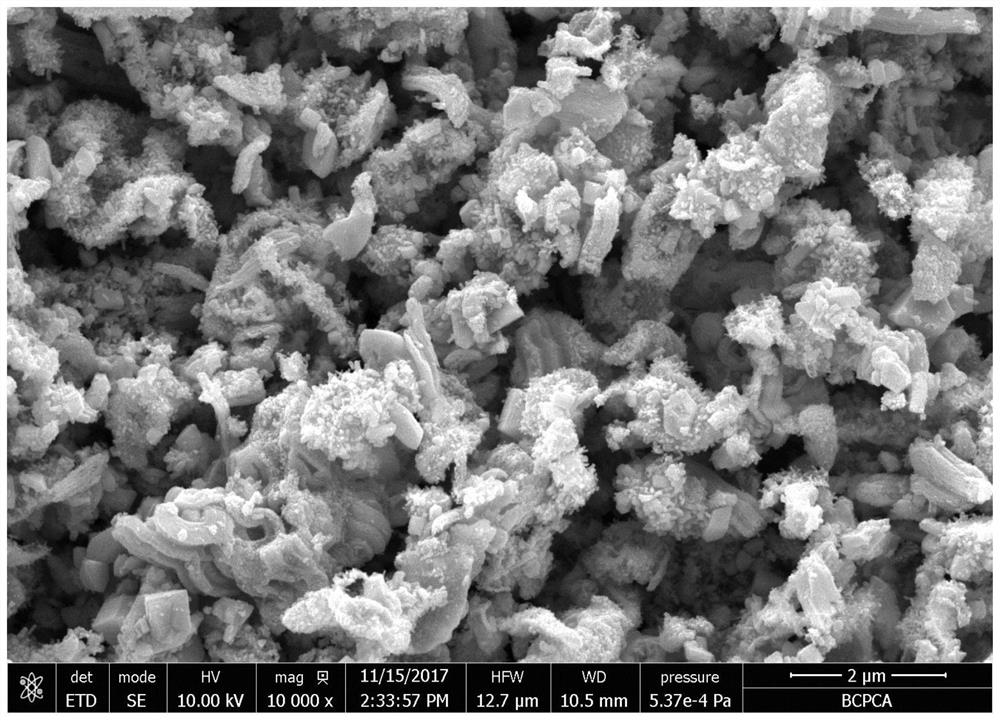

[0041] The invention provides a Pd-SnO 2 Nanocomposite material, its preparation method is specifically carried out according to the following steps:

[0042] (1) Weigh 3.17g SnCl 2 2H 2 O was dissolved in 20mL ethanol, stirred for 30min to dissolve, and then weighed 0.0125g of PdCl 2 Add 1.5mL 2M hydrochloric acid, dissolve it by ultrasonication for 30min, and then add it to the former. After stirring the mixed solution for 1.5 hours, slowly and evenly add 2g of SBA-15, and vigorously stir at room temperature for 6 hours. After the SBA-15 is completely dissolved, dry the sample at 80°C for 15 hours;

[0043] (2) Grind the sample obtained after drying in step (1) to turn the block sample into powder, then raise the temperature to 550°C at 5°C / min, and calcinate at 550°C for 6h;

[0044] (3) Remove SBA-15 from the sample obtained in step (2) with 60ml 4M NaOH, and stir at room temperature for 4 days;

[0045] (4) Dilute the alkaline solution in step (3) with 1000 mL of dis...

Embodiment 2

[0047] The invention provides a Pd-SnO 2 Nanocomposite material, its preparation method is specifically carried out according to the following steps:

[0048] (1) Weigh 3.17g SnCl 2 2H 2 O was dissolved in 20mL ethanol, stirred for 30min to dissolve, and then weighed 0.013g of PdCl 2 Add 1.5ml of 2M hydrochloric acid, dissolve it by ultrasonication for 30min, and then add it to the former. After stirring the mixed solution for 1.5 hours, slowly and evenly add 2g of SBA-15, and vigorously stir at room temperature for 5 hours. After the SBA-15 is completely dissolved, dry the sample at 80°C for 20 hours;

[0049] (2) Grind the sample obtained after drying in step (1) to turn the block sample into powder, then raise the temperature to 600°C at 3°C / min, and calcinate at 600°C for 4h;

[0050] (3) Remove SBA-15 from the sample obtained in step (2) with 60mL 2M NaOH, and stir at room temperature for 4 days;

[0051] (4) Wash the alkaline solution in step (3) by centrifugation s...

Embodiment 3

[0053] The invention provides a Pd-SnO 2 Nanocomposite material, its preparation method is specifically carried out according to the following steps:

[0054] (1) Weigh 3.17g SnCl 2 2H 2 O was dissolved in 20mL ethanol and stirred for 30min to dissolve it. Then weigh 0.0128g of PdCl 2 Add 1.5ml of 2M hydrochloric acid, dissolve it by ultrasonication for 30min, and then add it to the former. After the mixed solution was stirred for 1.5 hours, 1.8 g of SBA-15 was added slowly and evenly, and vigorously stirred at room temperature for 6 hours. After the SBA-15 was completely dissolved, the sample was dried at 80°C for 18 hours;

[0055] (2) Grind the sample obtained after drying in step (1) to turn the block sample into powder, then raise the temperature to 550°C at 3°C / min, and calcinate at 550°C for 6h;

[0056] (3) Use 60mL 2M NaOH to remove SBA-15 from the sample obtained in step (2), and stir at room temperature for 5 days;

[0057] (4) Dilute the alkaline solution in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com