Konjac jelly and preparation method thereof

A technology of konjac fine powder and konjac, which is applied in the field of food processing, can solve the problems of insufficient utilization, low antibacterial effect, poor production hygiene, etc., and achieve the effects of reducing the content of microorganisms, good chewiness, and good health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

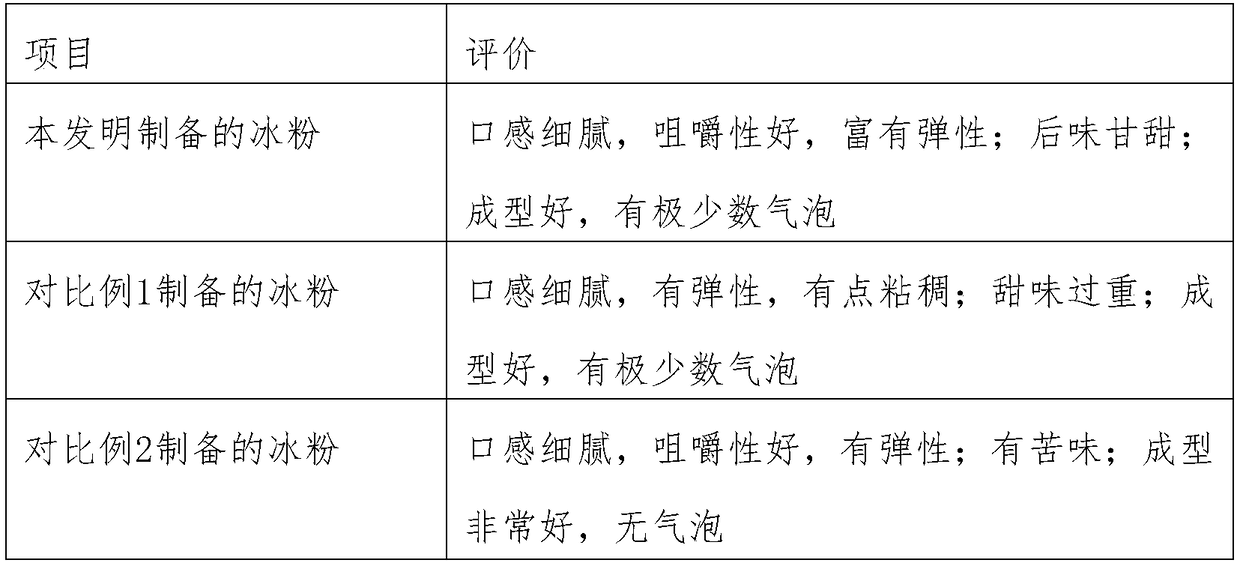

Examples

Embodiment 1

[0019] The invention relates to konjac ice powder. The raw materials include by weight: 15g of pseudophysalis seeds, 2g of konjac fine powder, 0.5g of calcium hydroxide solution, and 0.2g of additives.

[0020] Further, the concentration of the calcium hydroxide solution is 20%.

[0021] Further, the preparation of the konjac fine powder: wash the konjac tubers, scrape the epidermis, and cut into 2-4mm slices to obtain konjac slices; add an appropriate amount of edible alcohol to the konjac slices to soak for 2 hours, filter, and then konjac The slices are steamed in water, then dried, cooled, crushed, and passed through a 100-mesh sieve to obtain fine konjac powder.

[0022] Further, the additive includes the following raw materials in parts by mass: 1g peanut powder, 3g red date powder, 1g sesame, 3g brown sugar.

[0023] Further, the preparation of the additive: take brown sugar, add boiling water with 5 times the mass of brown sugar, stir until the brown sugar is complete...

Embodiment 2

[0031] The invention relates to konjac ice powder. The raw materials include by weight: 18g of pseudophysalis seeds, 3g of konjac powder, 0.6g of calcium hydroxide solution, and 0.3g of additives.

[0032] Further, the concentration of the calcium hydroxide solution is 19%.

[0033] Further, the preparation of the konjac fine powder: wash the konjac tubers, scrape the epidermis, cut into 2-4mm slices to obtain konjac slices; add an appropriate amount of edible alcohol to the konjac slices to soak for 2.5h, filter, and then The konjac slices are steamed over water, then dried, cooled, crushed, and passed through a 120-mesh sieve to obtain fine konjac powder.

[0034] Further, the additive includes the following raw materials in parts by mass: 1.5g peanut powder, 4g red date powder, 1.5g sesame, 4g brown sugar.

[0035] Further, the preparation of the additive: take brown sugar, add boiling water with 5.5 times the mass of brown sugar, stir until the brown sugar is completely d...

Embodiment 3

[0043] The invention relates to konjac ice powder. The raw materials include, by weight, 20 g of pseudophysalis seeds, 5 g of konjac powder, 1 g of calcium hydroxide solution, and 0.4 g of additives.

[0044] Further, the concentration of the calcium hydroxide solution is 18%.

[0045] Further, the preparation of the konjac fine powder: wash the konjac tubers, scrape the epidermis, and cut into 2-4mm slices to obtain konjac slices; add an appropriate amount of edible alcohol to the konjac slices to soak for 3 hours, filter, and then konjac The slices are steamed in water, then dried, cooled, crushed, and passed through a 120-mesh sieve to obtain fine konjac powder.

[0046] Further, the additive includes the following raw materials in parts by mass: 2g peanut powder, 5g red date powder, 2g sesame, and 5g brown sugar.

[0047] Further, the preparation of the additive: take brown sugar, add boiling water with 6 times the mass of brown sugar, stir until the brown sugar is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com