Cation exchange membrane based on cyclodextrin crosslinked polymer and preparation method and applications thereof

A technology of cation exchange membrane and cross-linked polymer, applied in the field of ion exchange membrane, can solve the problems of vanadium resistance, mechanical strength to be improved, low efficiency of vanadium battery, poor ion selectivity, etc., and achieves cheap raw material source and mechanical properties. Improve and reduce the effect of membrane molecular porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

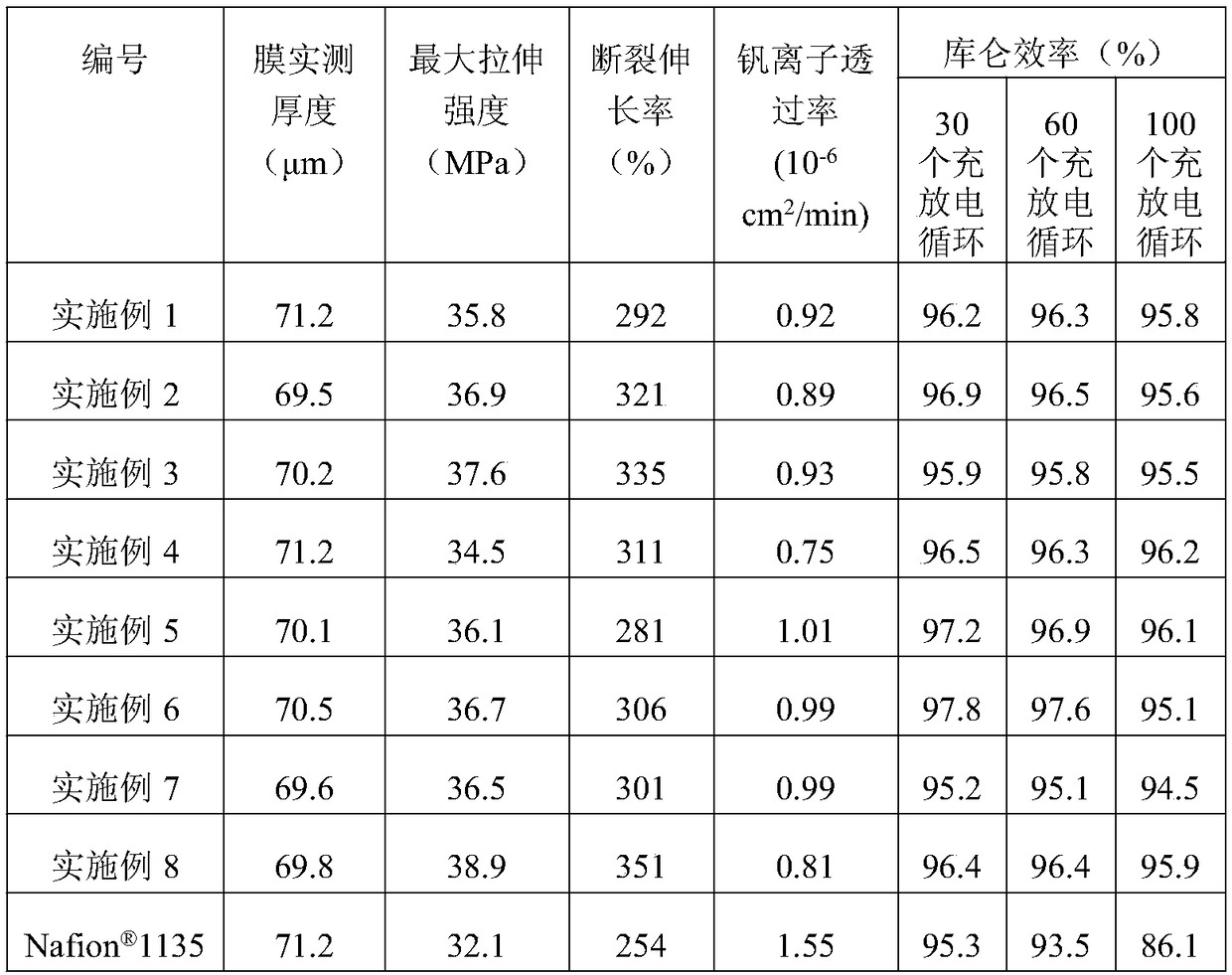

Examples

Embodiment 1

[0031] Disperse 113.5g of β-cyclodextrin (0.1mol) into 500mL of tap water with pH=1-2, stir well, add 81.1g of formaldehyde solution with a mass fraction of 37% (effective formaldehyde content is 1mol), and react at 40°C 8h, filter with suction, wash with deionized water, fully dry and pulverize to get powder; disperse the powder into anhydrous DMF, gradually add 10.86g of acryloyl chloride liquid under constant stirring, react at 65°C for 15h, and then pump it out with an oil pump The acryloyl chloride and the HCl gas generated in the system did not participate in the reaction, and the obtained dispersion liquid was gradually added dropwise to acetone to precipitate, washed three times with acetone, and dried to obtain a solid; to the obtained solid, add 3 times its mass (excess) Concentrated sulfuric acid, stirred at 0-5°C for 2 hours, then gradually added the reaction system to excess ice acetone (to precipitate the cyclodextrin polymer), then filtered and dried to obtain a ...

Embodiment 2

[0034] The difference between this example and Example 1 is that the amount of acryloyl chloride is 18.1 g, and the molar ratio of acryloyl chloride to β-cyclodextrin is 2:1.

Embodiment 3

[0036] The difference between this example and Example 1 is that the amount of acryloyl chloride used is 27.15 g, and the molar ratio of acryloyl chloride to β-cyclodextrin is 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com