Lithium-sulfur battery electrolyte and application thereof

A lithium-sulfur battery and electrolyte technology, which is applied in the direction of lithium batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of unstable sulfide ceramics, battery inoperability, and large contact resistance, so as to improve capacity performance and cycle Effects of stability, dissolution inhibition, and contact resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

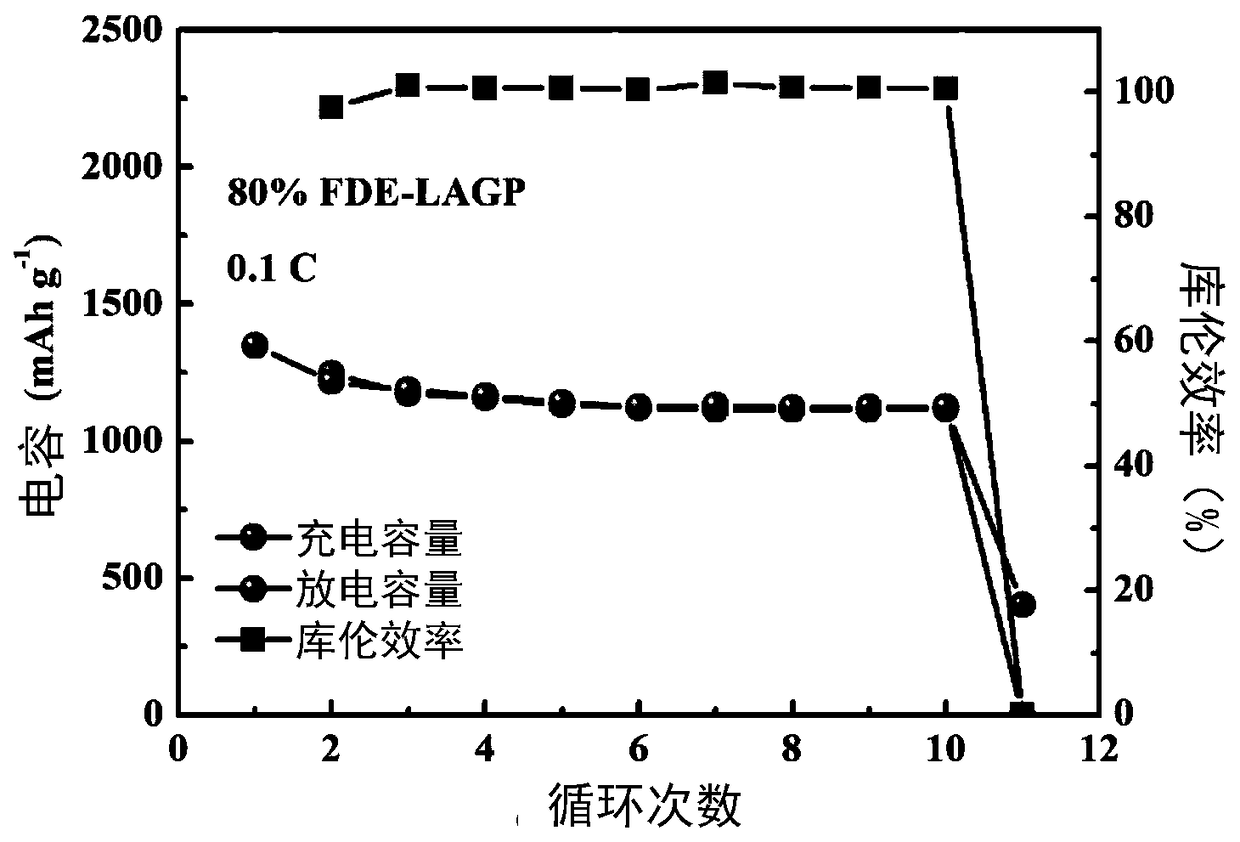

[0038] (1) LAGP (Li 1.5 al 0.5 Ge 1.5 (PO 4 ) 3 ) powder, after molding the LAGP powder, carry out cold isostatic pressing to obtain a green body, and finally sinter the green body to obtain a LAGP ceramic sheet;

[0039] (2) 1M lithium salt LiN(SO 2 CF 3 ) 2 Dissolve in fluoroether 1,3-(1,1,2,2-tetrafluoroethoxy)propane (4ml), cyclic ether 1,3-dioxolane (0.5ml) and linear ether glycol In the mixed solvent of dimethyl ether (0.5ml), obtain liquid electrolyte (such as Figure 7 middle a);

[0040] (3) Add the liquid electrolyte to the glass fiber membrane, and then paste it on both sides of the LAGP ceramic sheet as the electrolyte of the battery;

[0041] (4) Assemble a button-type lithium-sulfur battery. Dry the sulfur-containing S / C slurry and apply it on aluminum foil, cut into discs with a diameter of 12mm as the positive electrode, lithium metal as the negative electrode, and the electrolyte obtained in step (3), assemble the battery in an argon glove box .

...

Embodiment 2

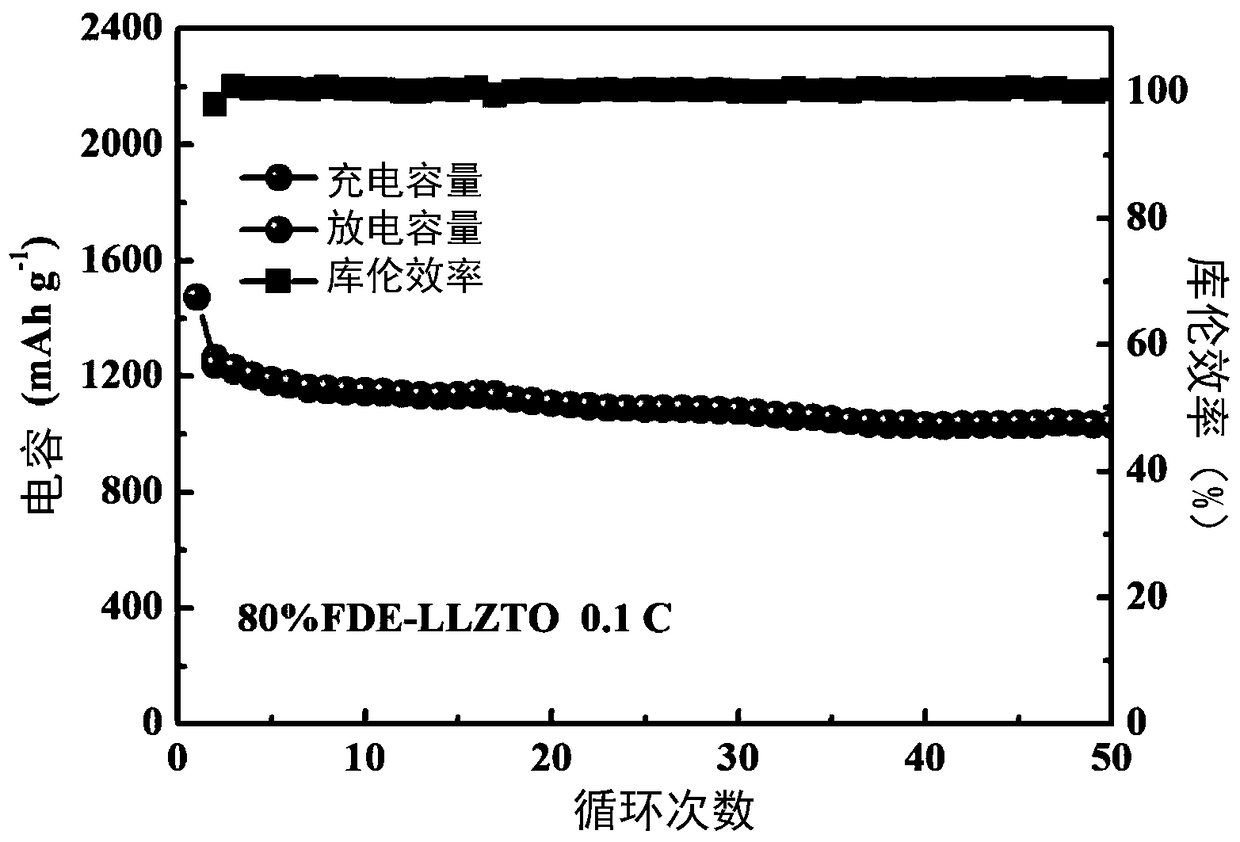

[0045] (1) Prepare LLZTO (Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 ) powder, after molding the LLZTO powder, carry out cold isostatic pressing to obtain a green body, preferably sintering the green body to obtain an LLZTO ceramic sheet;

[0046] (2) 1M lithium salt LiN(SO 2 CF 3 ) 2 Dissolve in fluoroether 1,3-(1,1,2,2-tetrafluoroethoxy)propane (4ml), cyclic ether 1,3-dioxolane (0.5ml) and linear ether glycol In the mixed solvent of dimethyl ether (0.5ml), obtain electrolytic solution;

[0047] (3) Add the liquid electrolyte to the glass fiber membrane, and then paste it on both sides of the LLZTO ceramic sheet as a mixed electrolyte;

[0048] (4) Assemble a button-type lithium-sulfur battery. Dry the sulfur-containing S / C slurry and apply it on the aluminum foil, cut it into a disc with a diameter of 12mm as the positive electrode, lithium metal as the negative electrode, and use the mixed electrolyte obtained in step (3) as the diaphragm, in an argon glove box Assemble the b...

Embodiment 3

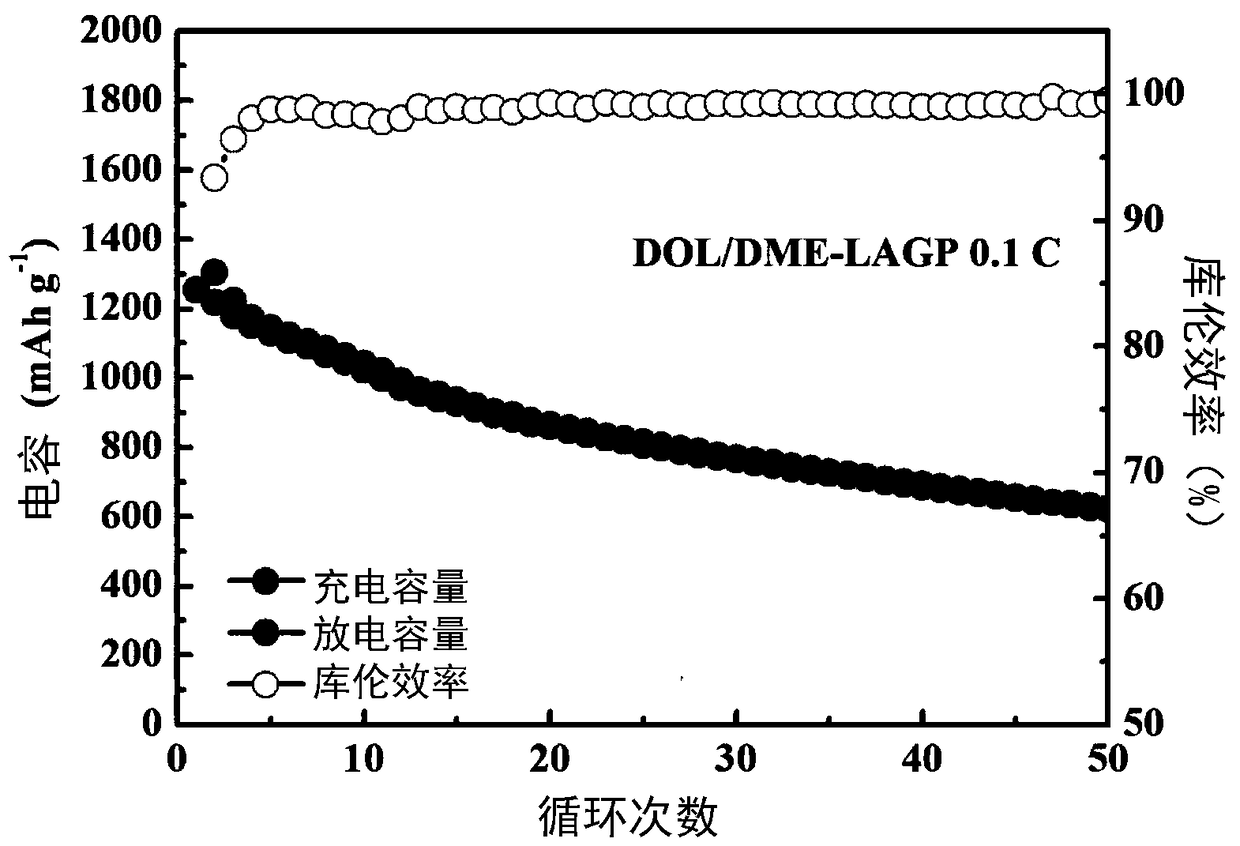

[0064] (1) LAGP (Li 1.5 al 0.5 Ge 1.5 (PO 4 ) 3 ) powder, after molding the LAGP powder, carry out cold isostatic pressing to obtain a green body, and finally sinter the green body to obtain a LAGP ceramic sheet;

[0065] (2) 1M lithium salt LiN(SO 2 CF 3 ) 2 Dissolve in 1,2-bis(1,1,2,2-tetrafluoroethoxy)ethane (4ml), cyclic ether 1,3-dioxolane (0.5ml) and linear ether glycol In the mixed solvent of dimethyl ether (0.5ml), obtain liquid electrolyte;

[0066] (3) Add the liquid electrolyte to the glass fiber membrane, and then paste it on both sides of the LAGP ceramic sheet as the electrolyte of the battery;

[0067] (4) Assemble a button-type lithium-sulfur battery. Dry the sulfur-containing S / C slurry and apply it on aluminum foil, cut into discs with a diameter of 12mm as the positive electrode, lithium metal as the negative electrode, and the electrolyte obtained in step (3), assemble the battery in an argon glove box .

[0068] Battery performance:

[0069] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com