Desugaring technology of hippophae rhamnoides fruit juice

The technology of sea buckthorn juice and sea buckthorn fruit is applied in the field of food processing, which can solve the problems of scavenging free radicals and inhibiting enzyme activity, and achieve the effects of simple and controllable desugarization process, less damage and high removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

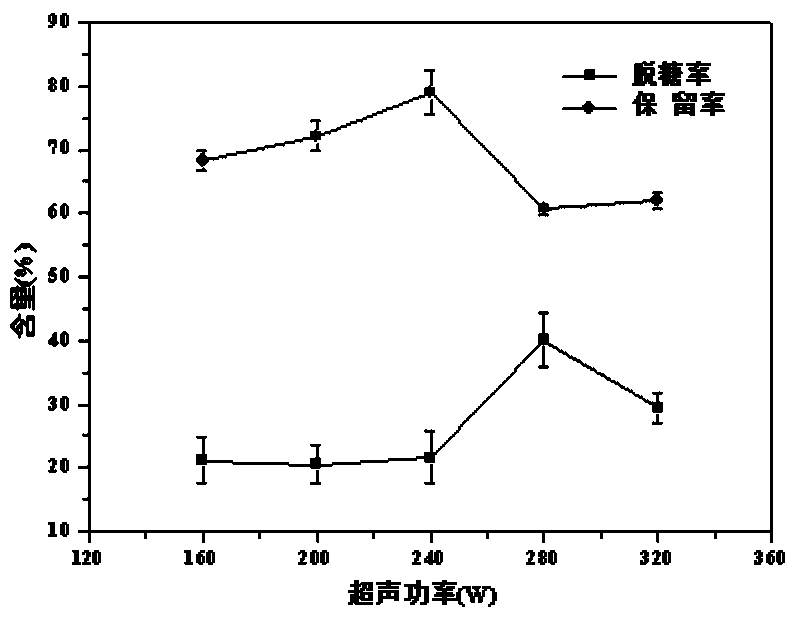

[0043]Take 300mL of refrigerated seabuckthorn juice stock solution, dilute it 5 times with distilled water and shake well for later use. In the following experiments, use the 5 times diluted seabuckthorn juice as the raw material, accurately measure 5 parts of 20mL seabuckthorn juice into a 250mL Erlenmeyer flask, and add 90mL of 90% Ethanol was sonicated at 70°C for 40 minutes, and then ethanol precipitated for 5 hours. The effects of ultrasonic powers of 160W, 200W, 240W, 280W and 320W on the removal rate of total sugar and the retention rate of total flavonoids were investigated. Then suction filtration, concentrate to measure the absorbance of sugar and flavonoids in the 100mL volumetric flask, measure three times, do three groups in parallel, calculate the retention rate of total sugar removal rate and total flavonoids, the result is as follows figure 1 .

[0044] Depend on figure 1 It can be seen that the retention rate of total flavonoids increases with the increase of...

Embodiment 2

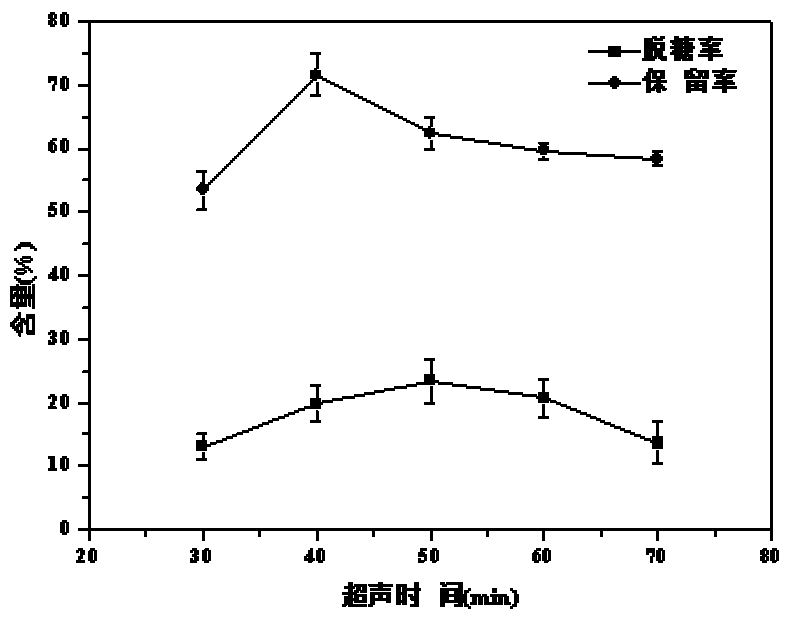

[0047] Take 300mL of refrigerated seabuckthorn juice stock solution, dilute it 5 times with distilled water and shake it up for later use. In the following experiments, seabuckthorn juice diluted 5 times will be used as the raw material; accurately measure 20mL of 5 parts of seabuckthorn juice in a 250mL Erlenmeyer flask, and add 90mL of 90 % ethanol in the ultrasonic temperature of 70 ℃, ultrasonic power of 200W, alcohol precipitation for 5h, to investigate the effect of ultrasonic time of 30, 40, 50, 60, 70min on the total sugar removal rate and total flavonoid retention rate of seabuckthorn juice. Then, concentrate by suction filtration into a 100mL volumetric flask to measure the absorbance of sugar and flavonoids, and measure three groups. Do three groups in parallel, calculate the total sugar removal rate and the retention rate of total flavonoids, the results are as follows figure 2 .

[0048] Depend on figure 2 It can be seen that the retention rate of total flavon...

Embodiment 3

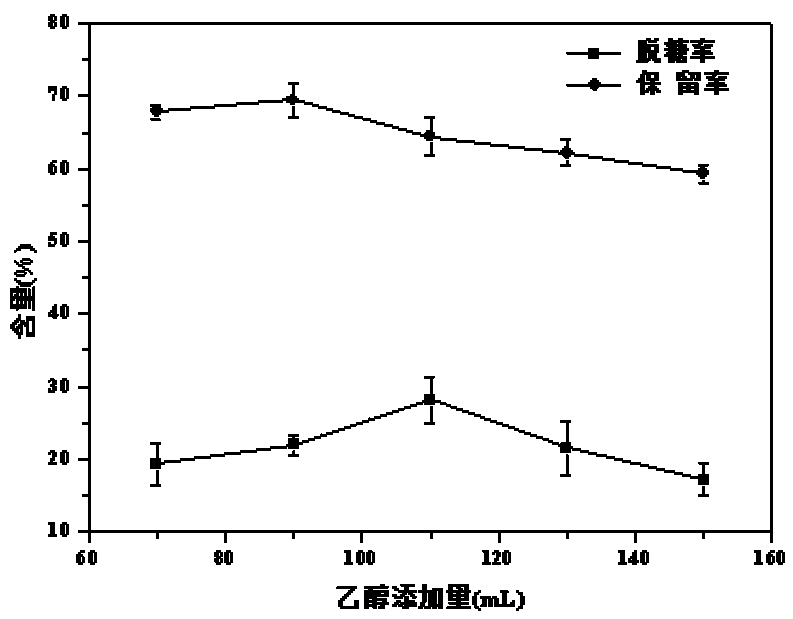

[0051] Take 300mL of refrigerated seabuckthorn juice stock solution, dilute it 5 times with distilled water and shake it up for later use. In the following experiments, use the 5 times diluted seabuckthorn juice as raw material, accurately measure 5 parts of 20mL seabuckthorn juice in a 250mL Erlenmeyer flask, and put it under ultrasonic temperature 70°C, ultrasonic power 200W, ultrasonic 40min, and alcohol precipitation for 5h to investigate the effect of adding 70, 90, 110, 130, 150mL of 90% ethanol on the total sugar removal rate and total flavonoid retention rate of seabuckthorn juice. Concentrate by suction filtration into a 100mL volumetric flask to measure the absorbance of sugar and flavonoids, and measure three groups. Do three groups in parallel, calculate the total sugar removal rate and the retention rate of total flavonoids, the results are as follows image 3 ;

[0052] Depend on image 3 It can be seen that before the amount of ethanol added is 90mL, the reten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com