A treatment method for volatile sulfur-containing organic waste gas

An organic waste gas, volatile technology, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of difficult and efficient treatment of volatile sulfur-containing VOCs, poor sulfur removal effect, secondary pollution, etc. Efficiency, zero emission, clean recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

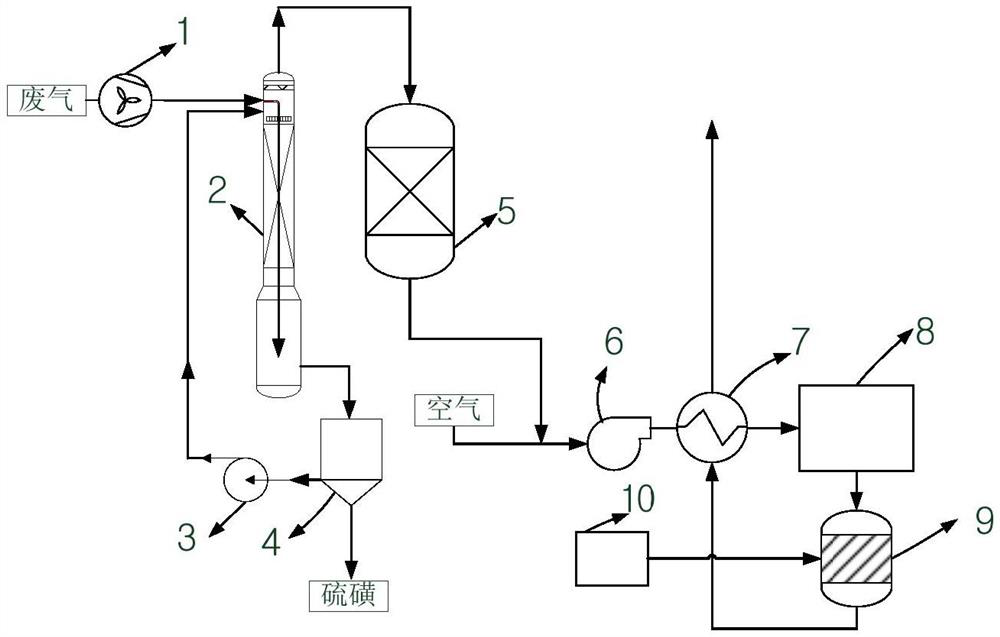

[0043] A treatment method for volatile sulfur-containing organic waste gas, comprising the steps of:

[0044] (1) Wet real-time regenerative desulfurization

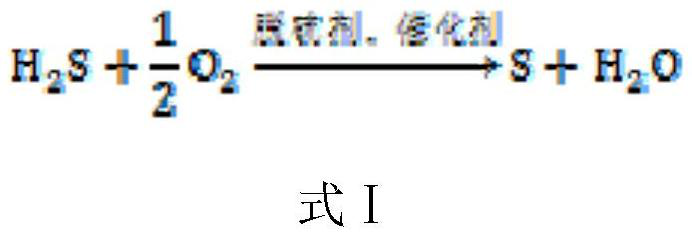

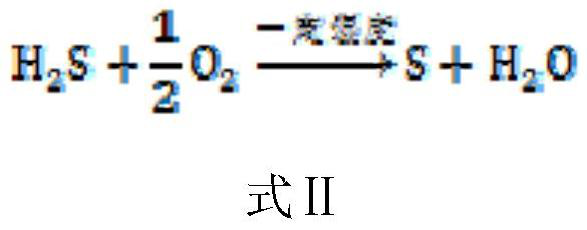

[0045] The organic waste gas is transported to the absorption tower through the intake pipeline, and the desulfurization agent and catalyst are installed in the absorption tower, and the organic waste gas fully contacts with the desulfurization agent and catalyst in the absorption tower to undergo a chemical reaction, so that the sulfide in the waste gas is converted into sulfur, desulfurization The final organic waste gas enters the next process through the top of the absorption tower, and the sulfur-containing desulfurizer passes through the sulfur filter to precipitate sulfur particles, and the desulfurizer is re-sent to the absorption tower by a circulating pump for recycling. The preparation method of the above catalyst includes the following steps : In a container equipped with epichlorohydrin, add dilute sulfuric ac...

Embodiment 2

[0054] A treatment method for volatile sulfur-containing organic waste gas, comprising the steps of:

[0055] (1) Wet real-time regenerative desulfurization

[0056] The organic waste gas is transported to the absorption tower through the intake pipeline, and the desulfurization agent and catalyst are installed in the absorption tower, and the organic waste gas fully contacts with the desulfurization agent and catalyst in the absorption tower to undergo a chemical reaction, so that the sulfide in the waste gas is converted into sulfur, desulfurization The final organic waste gas enters the next process through the top of the absorption tower, and the sulfur-containing desulfurizer passes through the sulfur filter to precipitate sulfur particles, and the desulfurizer is re-sent to the absorption tower by a circulating pump for recycling. The preparation method of the above catalyst includes the following steps : In a container equipped with epichlorohydrin, add dilute sulfuric ...

Embodiment 3

[0065] A treatment method for volatile sulfur-containing organic waste gas, comprising the steps of:

[0066] (1) Wet real-time regenerative desulfurization

[0067] The organic waste gas is transported to the absorption tower through the intake pipeline, and the desulfurization agent and catalyst are installed in the absorption tower, and the organic waste gas fully contacts with the desulfurization agent and catalyst in the absorption tower to undergo a chemical reaction, so that the sulfide in the waste gas is converted into sulfur, desulfurization The final organic waste gas enters the next process through the top of the absorption tower, and the sulfur-containing desulfurizer passes through the sulfur filter to precipitate sulfur particles, and the desulfurizer is re-sent to the absorption tower by a circulating pump for recycling. The preparation method of the above catalyst includes the following steps : In a container equipped with epichlorohydrin, add dilute sulfuric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com