Method for preparing activated carbon by using microalgae-alginate composite

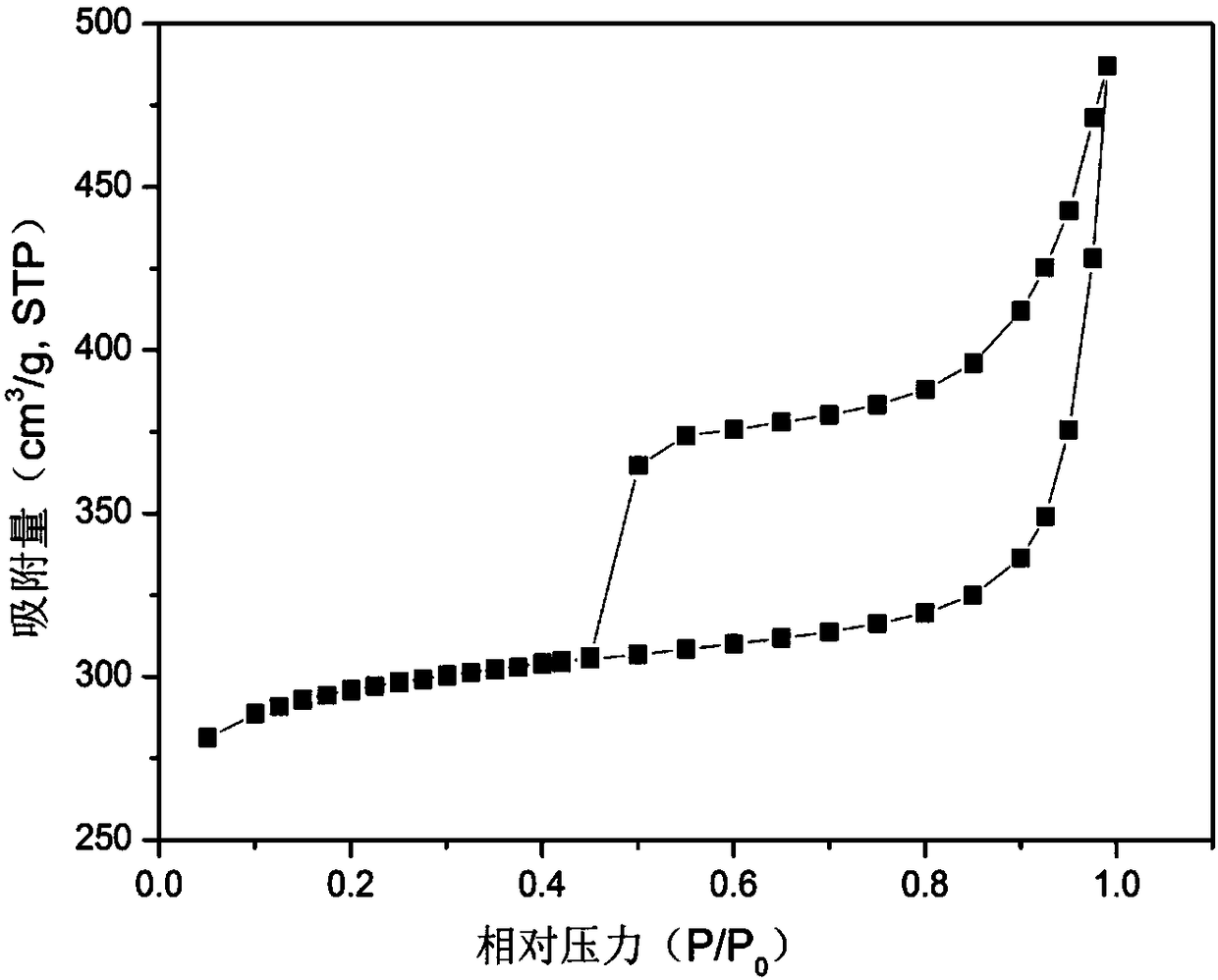

A technology for preparing activated carbon and alginate, applied in carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of reducing the specific surface area of activated carbon, and achieve the effect of abundant utilization, large specific surface area and rich micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of activated carbon with flat algae-sodium alginate complex as raw material

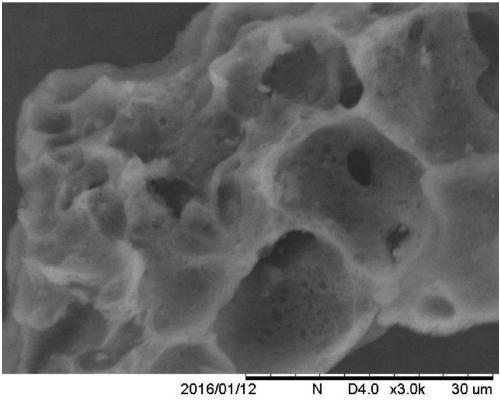

[0037] First, in a beaker, evenly disperse 25g of algae powder in deionized water, add sodium alginate and mix evenly, wherein the mass ratio of algae and sodium alginate is 1:2, and dry naturally to obtain alginate-alginic acid sodium complex. Then, in a tube furnace, under a nitrogen atmosphere (N 2 The flow rate is 120ml / min), at a heating rate of 2.5 °C / min, the resulting composite is heated to 500 °C for carbonization reaction for 1 h; Cool down to room temperature, take out the reaction product, and wash it three times with 1M HCl solution, then wash it with deionized water until neutral; finally dry it in an oven at 110°C for 12 hours to obtain the finished activated carbon. figure 1 It is the SEM figure of the activated carbon obtained according to the embodiment of the present invention 1, and the obtained activated carbon has a special structure and has ab...

Embodiment 2

[0038] Example 2: Preparation of activated carbon with Scenedesmus-sodium alginate compound as raw material

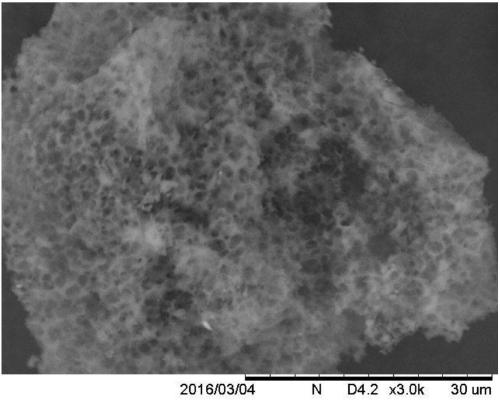

[0039] First, in a beaker, disperse 25g Scenedesmus powder in deionized water evenly, add sodium alginate and mix uniformly to obtain alginic acid-alginate complex, then add potassium hydroxide and mix uniformly to obtain a mixture, and then dry naturally, of which The mass ratio of algae, sodium alginate and potassium hydroxide is 1:1:1. Under nitrogen atmosphere (N 2 The flow rate is 120ml / min), and the resulting mixture is heated to 500°C at a heating rate of 2.5°C / min for carbonization reaction for 1h; then the temperature is raised to 700°C at a heating rate of 5°C / min for 2h activation. After cooling down to room temperature under a nitrogen atmosphere, the reaction product was taken out, washed three times with 1M HCl solution, and then washed with deionized water until neutral; finally, it was dried in an oven at 110°C for 12 hours to obtain the finished activ...

Embodiment 3

[0040] Embodiment 3: Preparation of activated carbon with golden algae-potassium alginate complex as raw material

[0041] First, in a beaker, disperse 25g of golden algae evenly in deionized water, add potassium alginate and mix evenly, wherein the mass ratio of golden algae to potassium alginate is 1:1, and dry naturally to obtain golden algae-alginic acid potassium complex. Then, in a tube furnace, under a nitrogen atmosphere (N 2 The flow rate is 120ml / min), and at a heating rate of 2.5 °C / min, the resulting composite is heated to 500 °C to perform carbonization reaction on the complex for 1 h; then the temperature is raised to 700 °C at a heating rate of 5 °C / min for 1 h activation , the temperature was lowered to room temperature in a nitrogen atmosphere, the reaction product was taken out, and it was washed three times with a 1M HCl solution, and then washed with deionized water until neutral; finally, it was dried in an oven at 110°C for 12 hours to obtain a finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com