Method for preparing activated carbon by using microalgae-alginate compound

A technology for preparing activated carbon and alginate, which is applied in the fields of carbon compounds, chemical instruments and methods, and inorganic chemistry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of activated carbon with flat algae-sodium alginate complex as raw material

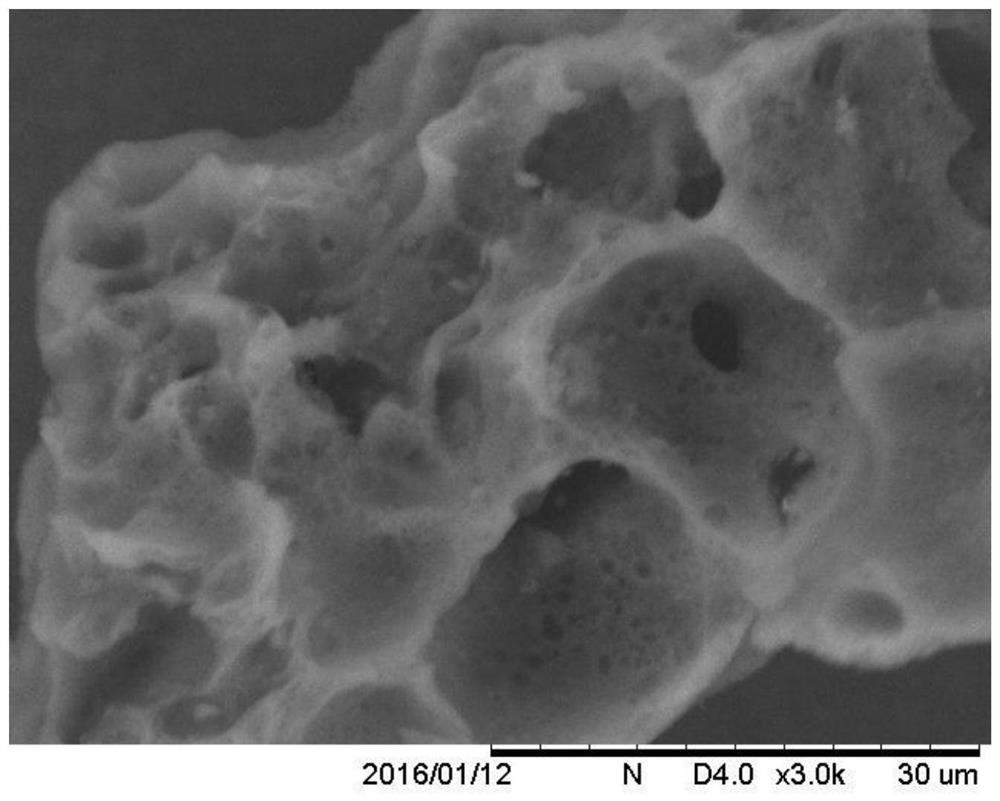

[0037] First, in a beaker, evenly disperse 25g of algae powder in deionized water, add sodium alginate and mix evenly, wherein the mass ratio of algae and sodium alginate is 1:2, and dry naturally to obtain alginate-alginic acid sodium complex. Then, in a tube furnace, under a nitrogen atmosphere (N 2 The flow rate is 120ml / min), at a heating rate of 2.5 °C / min, the resulting composite is heated to 500 °C for carbonization reaction for 1 h; Cool down to room temperature, take out the reaction product, and wash it three times with 1M HCl solution, then wash it with deionized water until neutral; finally dry it in an oven at 110°C for 12 hours to obtain the finished activated carbon. figure 1 It is the SEM figure of the activated carbon obtained according to the embodiment of the present invention 1, and the obtained activated carbon has a special structure and has ab...

Embodiment 2

[0038] Example 2: Preparation of activated carbon with Scenedesmus-sodium alginate compound as raw material

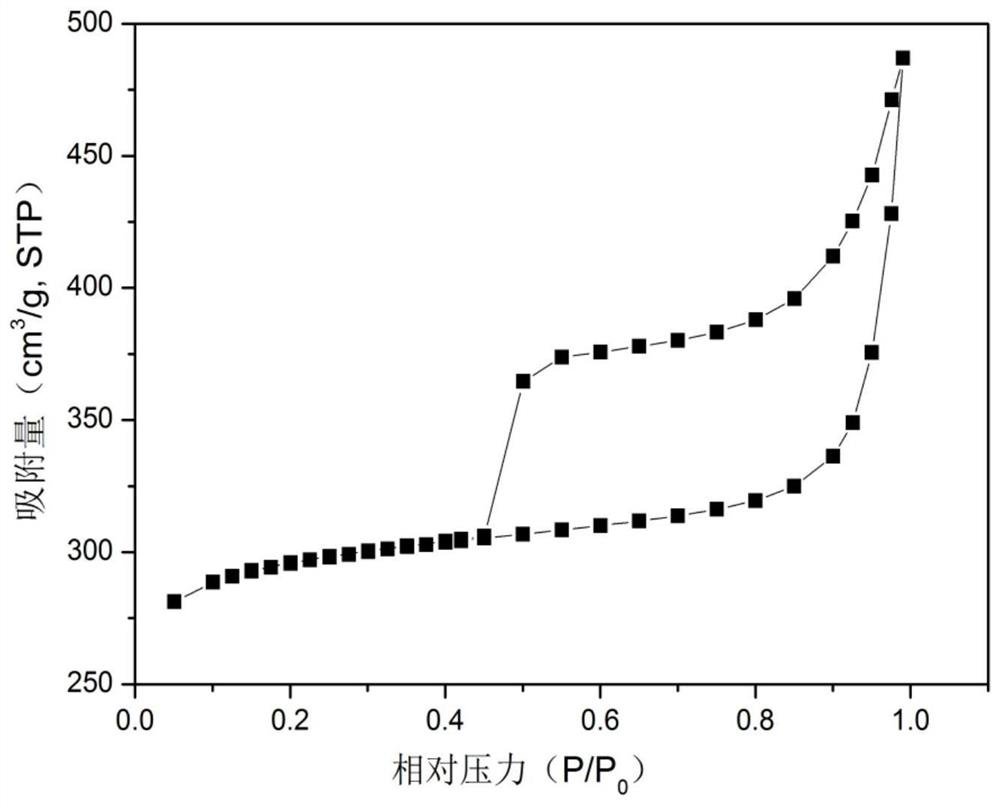

[0039] First, in a beaker, disperse 25g Scenedesmus powder in deionized water evenly, add sodium alginate and mix uniformly to obtain alginic acid-alginate complex, then add potassium hydroxide and mix uniformly to obtain a mixture, and then dry naturally, of which The mass ratio of algae, sodium alginate and potassium hydroxide is 1:1:1. Under nitrogen atmosphere (N 2 The flow rate is 120ml / min), and the resulting mixture is heated to 500°C at a heating rate of 2.5°C / min for carbonization reaction for 1h; then the temperature is raised to 700°C at a heating rate of 5°C / min for 2h activation. After cooling down to room temperature under a nitrogen atmosphere, the reaction product was taken out, washed three times with 1M HCl solution, and then washed with deionized water until neutral; finally, it was dried in an oven at 110°C for 12 hours to obtain the finished activ...

Embodiment 3

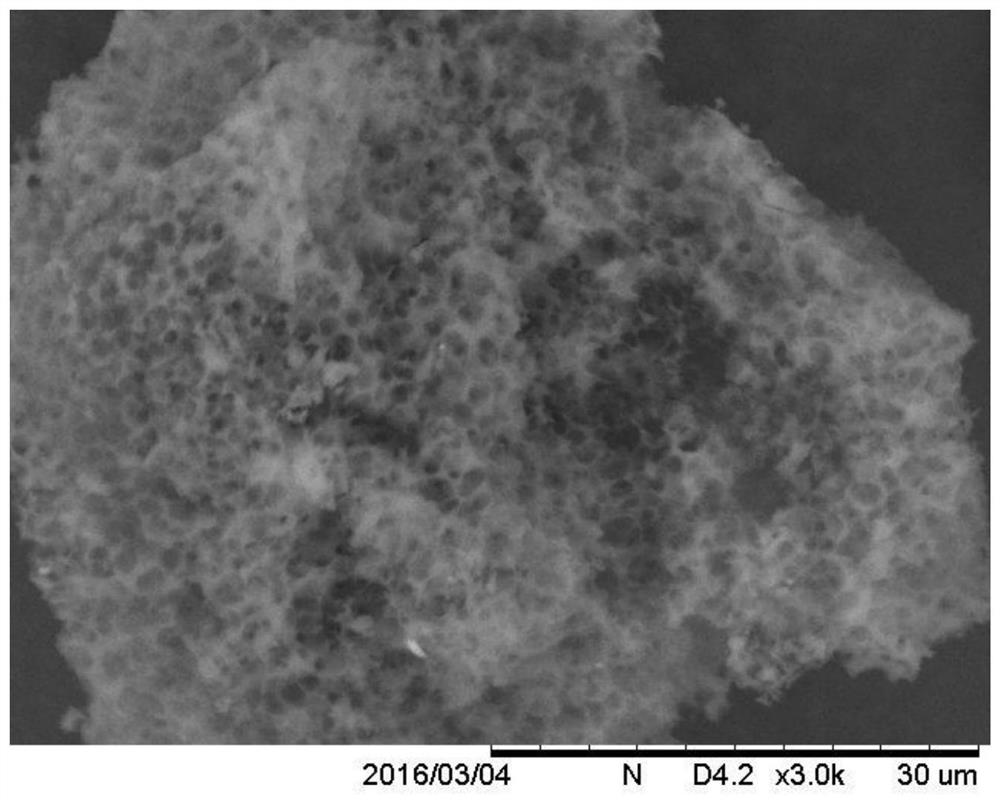

[0040] Embodiment 3: Preparation of activated carbon with golden algae-potassium alginate complex as raw material

[0041] First, in a beaker, disperse 25g of golden algae evenly in deionized water, add potassium alginate and mix evenly, wherein the mass ratio of golden algae to potassium alginate is 1:1, and dry naturally to obtain golden algae-alginic acid potassium complex. Then, in a tube furnace, under a nitrogen atmosphere (N 2 The flow rate is 120ml / min), and at a heating rate of 2.5 °C / min, the resulting composite is heated to 500 °C to perform carbonization reaction on the complex for 1 h; then the temperature is raised to 700 °C at a heating rate of 5 °C / min for 1 h activation , the temperature was lowered to room temperature in a nitrogen atmosphere, the reaction product was taken out, and it was washed three times with a 1M HCl solution, and then washed with deionized water until neutral; finally, it was dried in an oven at 110°C for 12 hours to obtain a finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com