Rapid sludge culture method capable of achieving sewage nitrite accumulation

A technology of nitrite and cultivation method, which is applied in the field of rapid cultivation of sludge to realize the accumulation of nitrite in sewage, can solve the problems of low nitrite concentration, complexity, reduction of aeration, etc., and achieve good treatment effect and low activity Rebound, inhibition effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

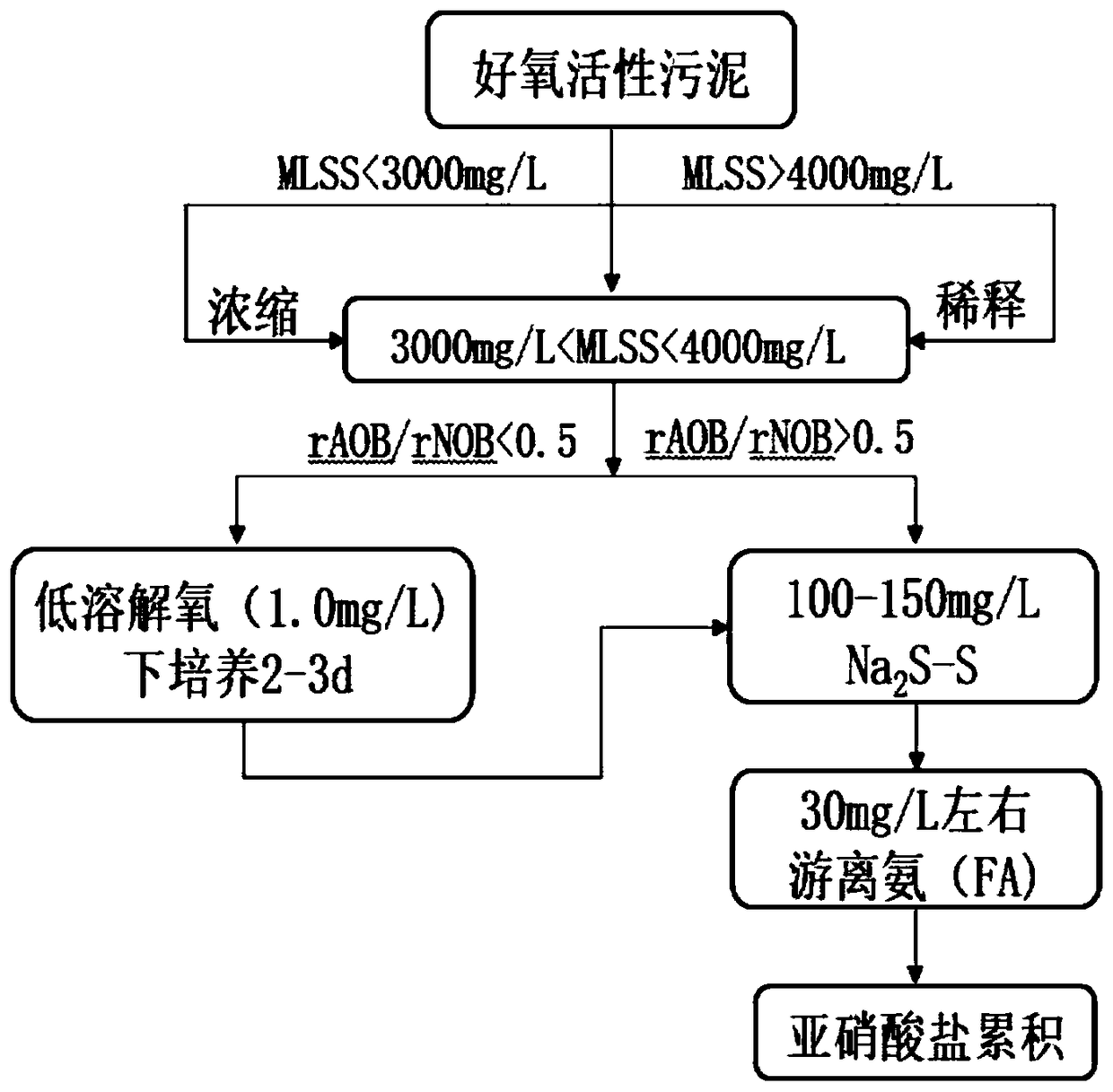

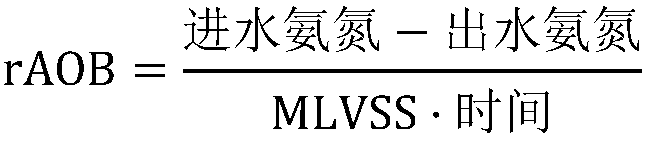

[0025] This example is about the treatment method of nitrite accumulation in activated sludge that has higher activity of ammonia oxidizing bacteria after being concentrated or diluted after washing, that is, when rAOB / rNOB>0.5.

[0026]The activated sludge is activated sludge from the aerobic section of a sewage treatment plant in Nanjing. The concentration of the activated sludge was determined to be 3500 mg / L, without dilution or concentration. After washing twice with clean water to maintain the original sludge concentration, the rAOB / The rNOB value is 0.58>0.5, no enrichment of ammonia oxidizing bacteria is required, and the activated sludge system only treated with the same concentration of free ammonia is used for comparison.

[0027] Add Na to the reactor 2 S makes its concentration 100mg / L Na 2 S-S, add a certain amount of Na 2 S, use 0.5mol / L hydrochloric acid to adjust the pH to about 7.2, and stir under anaerobic conditions. In the first stage, use a magnetic st...

Embodiment 2

[0030] This embodiment is a treatment method for treating activated sludge to form nitrite nitrogen accumulation under the condition that the activated sludge has relatively low ammonia oxidizing bacteria (AOB) activity, that is, when rAOB / rNOB<0.5.

[0031] The activated sludge is activated sludge from the aerobic nitrification reaction section of a sewage treatment plant in Nanjing. The sludge concentration was determined to be 5200mg / L. After washing with clean water, the activated sludge concentration was diluted to 3000mg / L in proportion. Its rAOB / rNOB value is 0.412 S makes its concentration reach 150mg / L Na 2 S-S, and use 0.5mol / L hydrochloric acid to adjust the pH to 7.2, and stir under anaerobic conditions. In the first stage, use a magnetic stirring rod for stirring treatment, the stirring speed is 1500r / min, and the stirring time is 5h. The second stage , the stirring speed is 900r / min, and the stirring time is 10h. In the third stage, the stirring speed is controll...

Embodiment 3

[0035] This example is the treatment process of the activated sludge under the condition that the activated sludge has relatively high ammonia oxidizing bacteria (AOB) activity, that is, when rAOB / rNOB>0.5.

[0036] The activated sludge is activated sludge from the aerobic nitrification reaction section of a sewage treatment plant in Nanjing. The sludge concentration was determined to be 2600mg / L. After washing with clean water, the activated sludge concentration was concentrated to 4000mg / L in proportion. Its rAOB / rNOB value is 0.62>0.5, no need to enrich ammonia oxidizing bacteria (AOB), add Na to the reactor 2 S makes its concentration reach 125mg / L Na 2 S-S, and use 0.5mol / L hydrochloric acid to adjust the pH to 7.2, and stir under anaerobic conditions. In the first stage, use a magnetic stirring bar to stir, the stirring speed is 1300r / min, and the stirring time is 4h. When stirring, ensure 50% of the activated sludge is in a suspended state. In the second stage, the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com