Polyol composition and polyurethane hard foam plastic prepared therefrom

A polyol composition and a rigid plastic technology, applied in the field of polyurethane foam plastics, can solve the problems of large cells of polyurethane rigid foam, poor storage stability of polyols, and high cost of epoxy reaction, and reduce the cell size of the foam and improve the Storage stability, easy-to-obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

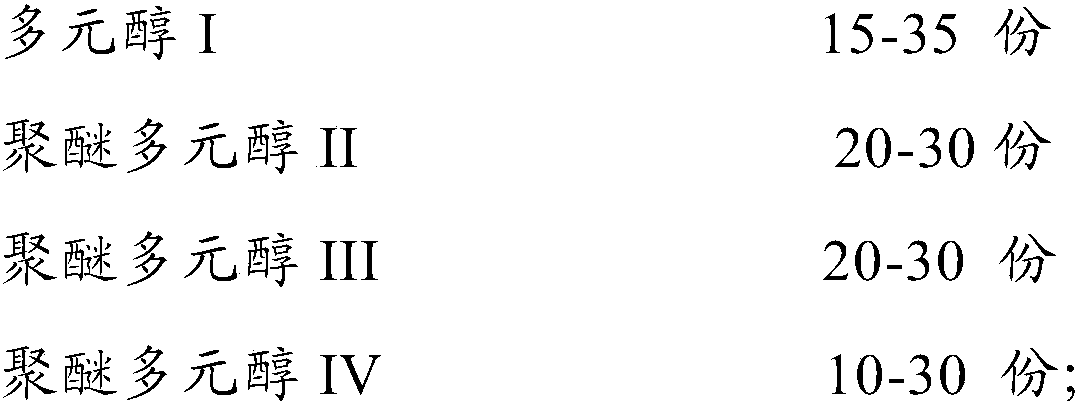

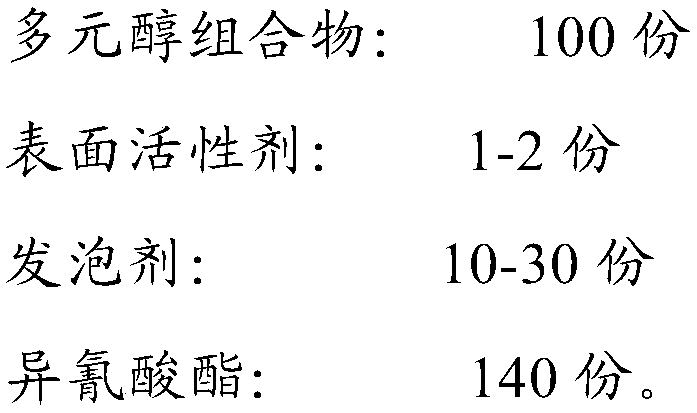

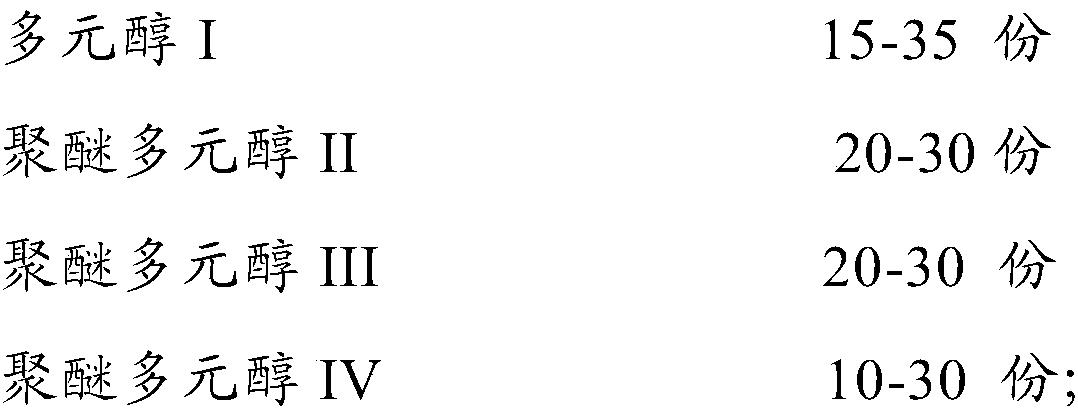

Method used

Image

Examples

Embodiment 1

[0067] This embodiment discloses a polyol I and a preparation method thereof. The polyol I is prepared by reacting cardanol glycidyl ether, diethanolamine, and oxyalkylene. The specific preparation process is as follows:

[0068] Add 120g of diethanolamine to the reaction kettle, raise the temperature to 70°C, then add 360g of cardanol glycidyl ether dropwise, after the dropwise addition is completed, keep warm for 3 hours, replace the gas in the reaction kettle with nitrogen, and then add 2000g of epoxy Butane, and add 2g KOH catalyst, raise the temperature to 130°C, keep the temperature for 5 hours, then cool down to 50°C and discharge;

[0069] The typical characteristic viscosity of the prepared polyol I is 1600-2100 mPa·s, and the hydroxyl value is 320-360 mg KOH / g.

[0070] In order to verify the compatibility between this polyol and cyclopentane, add 100g of this polyol into a glass bottle at room temperature of 20°C, then add 20g of cyclopentane, and stir at a high spe...

Embodiment 2

[0072] This embodiment discloses a polyol I and a preparation method thereof. The polyol I is prepared by reacting cardanol glycidyl ether, butylamine, and oxyalkylene. The specific preparation process is as follows:

[0073] Add 80g of butylamine into the reaction kettle, raise the temperature to 80°C, then add 800g of cardanol glycidyl ether dropwise, after the dropwise addition is completed, keep warm for 2 hours, replace the gas in the reaction kettle with nitrogen, and then add 800g of epoxy ethane, and 1g of KOH catalyst was added, the temperature was raised to 130°C, and after 6 hours of heat preservation reaction, the temperature was lowered to 40°C and the material was discharged.

[0074] The typical characteristic viscosity of the prepared polyol I is 1500-1800 mPa·s, and the hydroxyl value is 300-340 mg KOH / g.

[0075] In order to verify the compatibility between this polyol and cyclopentane, add 100g of this polyol into a glass bottle at room temperature 25°C, the...

Embodiment 3

[0077] This embodiment discloses a polyol I and a preparation method thereof. The polyol I is prepared by reacting cardanol glycidyl ether, laurylamine, and oxyalkylene. The specific preparation process is as follows:

[0078] Add 200g of dodecylamine into the reaction kettle, raise the temperature to 75°C, then add 800g of cardanol glycidyl ether dropwise, after the dropwise addition is completed, keep warm for 3 hours, replace the gas in the reaction kettle with nitrogen, and then add 800g of ring Oxyethane, and 2g KOH catalyst was added, the temperature was raised to 130°C, and after 6 hours of heat preservation reaction, the temperature was lowered to 40°C and the material was discharged.

[0079] The typical characteristic viscosity of the prepared polyol I is 1700-1900 mPa·s, and the hydroxyl value is 310-340 mg KOH / g.

[0080] In order to verify the compatibility between this polyol and cyclopentane, add 100g of this polyol into a glass bottle at room temperature 25°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com