A preparation method of laser cladding wear-resistant plate based on synchronous progressive shear deformation

A technology of shear deformation and laser cladding, which is applied in the direction of coating, metal material coating process, etc., to achieve the effect of high dislocation density, excellent comprehensive mechanical properties, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A laser cladding wear-resistant plate preparation method based on synchronous progressive shear deformation, comprising:

[0022] (1) Sandblasting the surface of the substrate to obtain a certain degree of cleanliness and roughness.

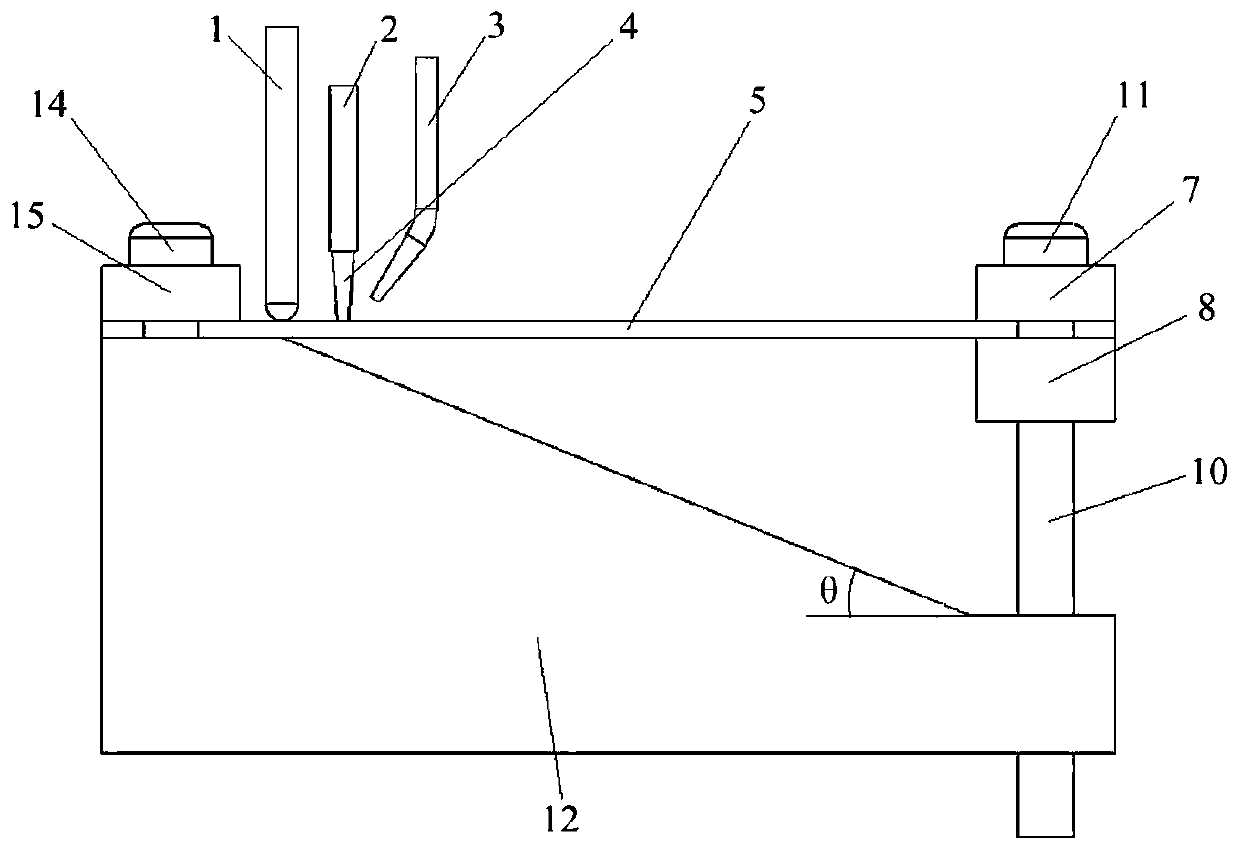

[0023] (2) According to figure 1 , the substrate was fixed on the device, and the thickness of the substrate was 4 mm.

[0024] (3) Under the protection of argon gas, laser cladding is carried out on the substrate, using synchronous powder feeding method, the cladding material is Ni60, the laser power is 3000W, the spot diameter is 4mm, the overlap rate is 30%, and the scanning speed is 10mm / s.

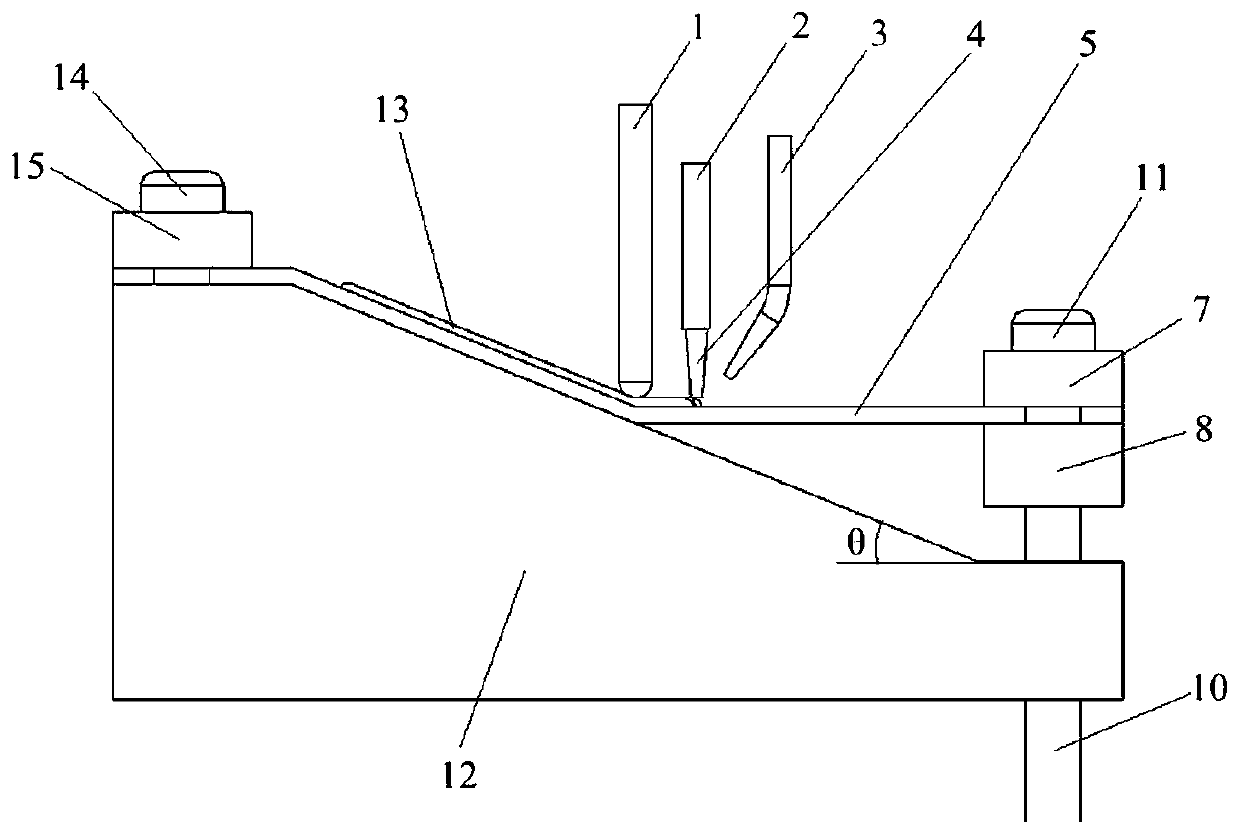

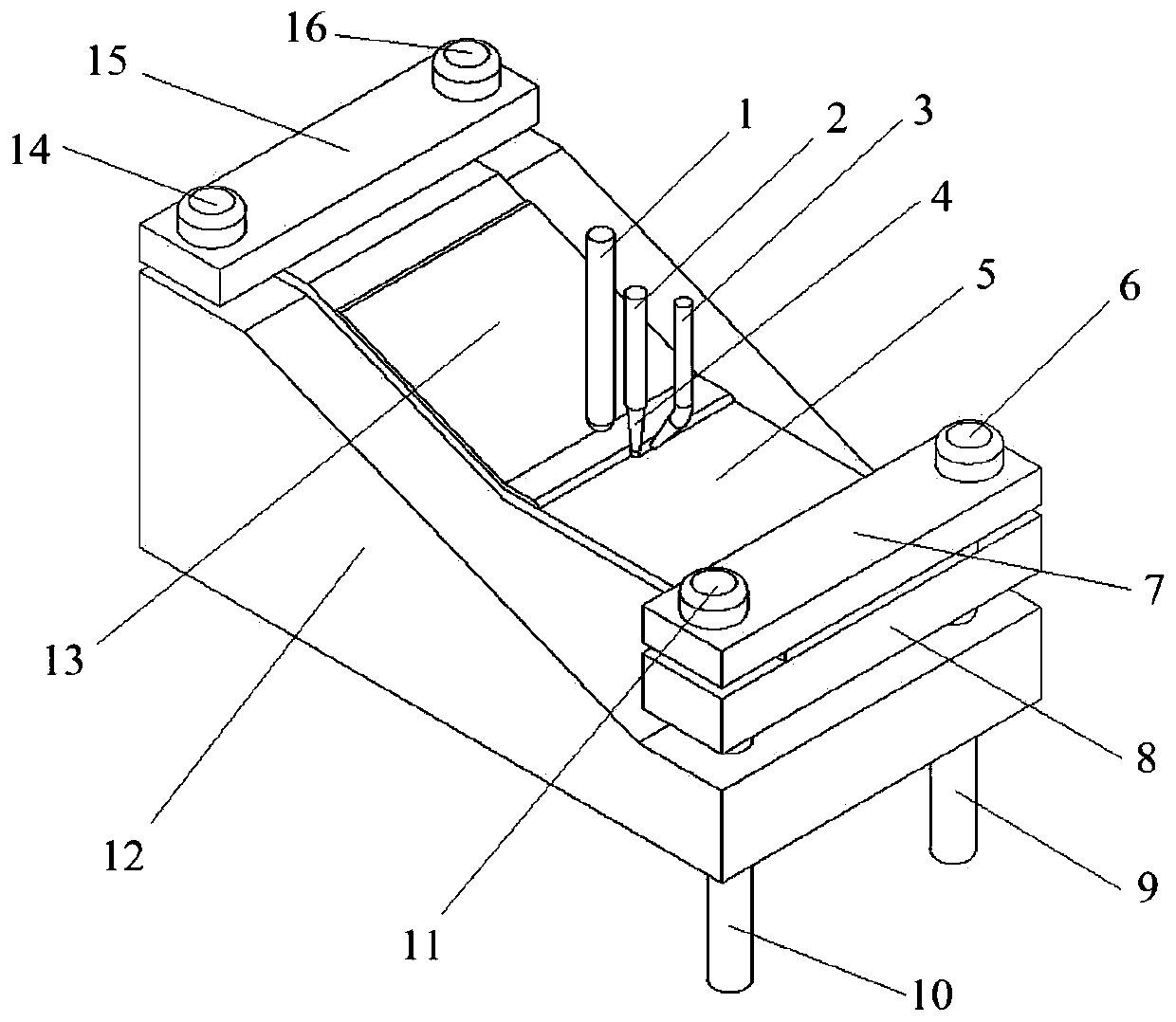

[0025] (4) Synchronously with the laser cladding, a ball head cutter with a radius of 4mm follows the molten pool to carry out gradual shear deformation on the cladding plate to make it fit the supporting slope, such as figure 2 and image 3 shown. The ball head cutter and the laser head are fixed on the same reference object. When the ball h...

Embodiment 2

[0029] Other operations of this embodiment are the same as those in Embodiment 1, except that the cladding material is NiCrBSi self-fluxing alloy powder, and its chemical composition is (wt%): 17.0Cr, 3.5B, 4.0Si, 1.0C, <12Fe, The rest is Ni.

[0030] The laser cladding plate obtained in this example was tested, and the average microhardness of the cladding layer section reached 946HV, compared with the cladding layer (787HV) prepared under the same conditions and parameters without synchronous progressive shear deformation. An increase of 20.2%. In the friction and wear test, there is no peeling phenomenon of cladding layer.

Embodiment 3

[0032] The other operations of this embodiment are the same as in Embodiment 1, the difference is that the cladding material is CoCrW cobalt-based alloy powder, and its chemical composition is (wt%): 29.9Cr, 4.5W, 0.99C, 3.0Ni, 1.4Si, and For Co.

[0033] The laser cladding plate obtained in this example was tested, and the average microhardness of the cladding layer section reached 1178HV, compared with the cladding layer (974HV) prepared under the same conditions and parameters without synchronous progressive shear deformation. An increase of 20.9%. In the friction and wear test, there is no peeling phenomenon of cladding layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com