Electrochemical sensor applied to direct methanol fuel cell as well as preparation method and application thereof

A fuel cell and electrochemical technology, applied in the field of electrochemistry, can solve the problems of restricting the oxidation of methanol, poor dispersion of Pt nanoparticles, wide particle size range, etc., and achieve uniform particle size, significant catalytic effect, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Chemical reagents and equipment:

[0046] Graphene oxide, polyethyleneimine, absolute ethanol, hydrochloric acid, sodium hydroxide, ultrapure water.

[0047] pHS-3B precision pH meter, vortex mixer, centrifuge, ultrasonic cleaner.

[0048] Buffer solution: 0.1mol L -1 Potassium dihydrogen phosphate solution, 0.1mol·L -1 Sodium hydroxide solution, containing 2mM [Fe(CN) 6 ] 3– / 4– of 0.1M phosphate buffer.

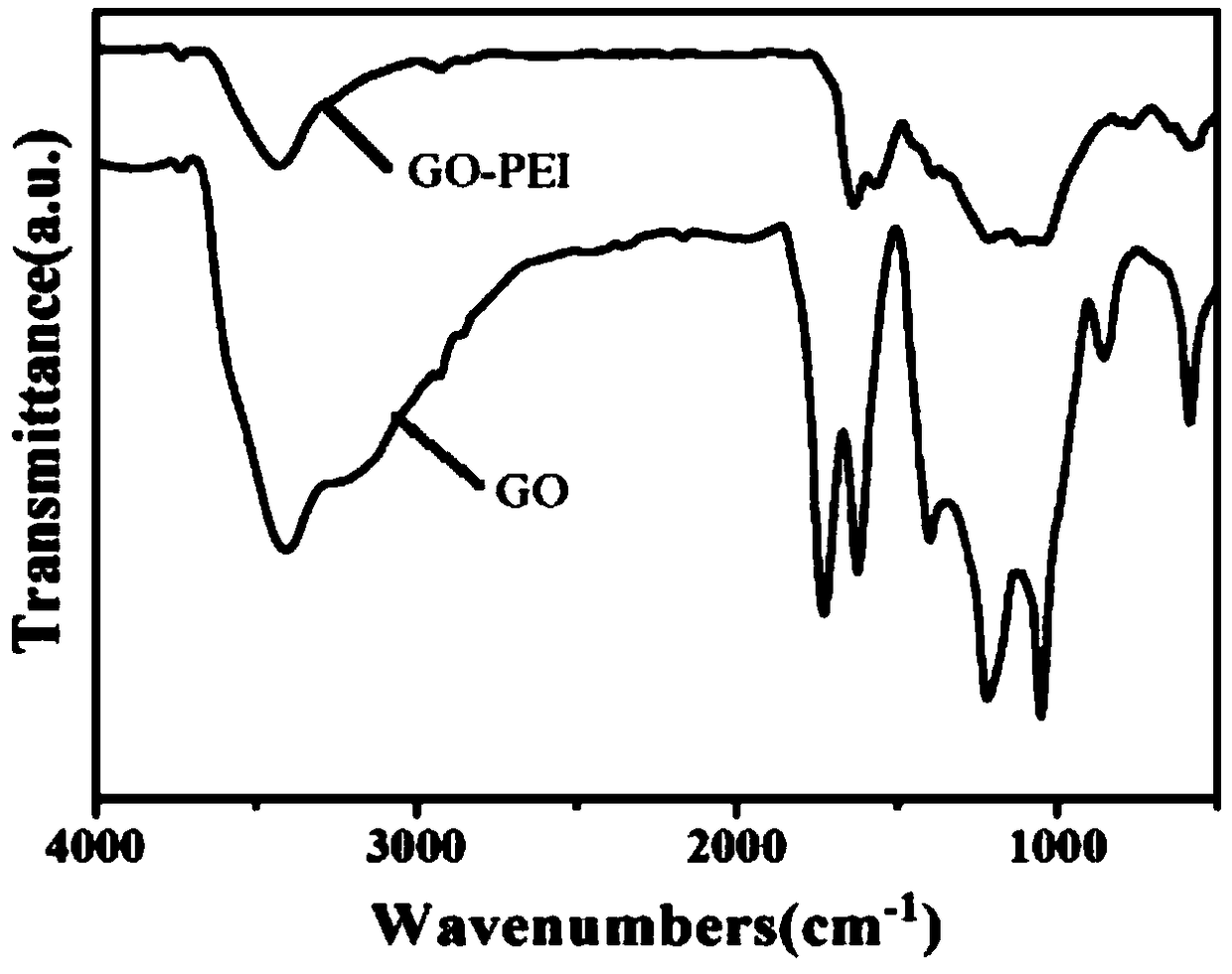

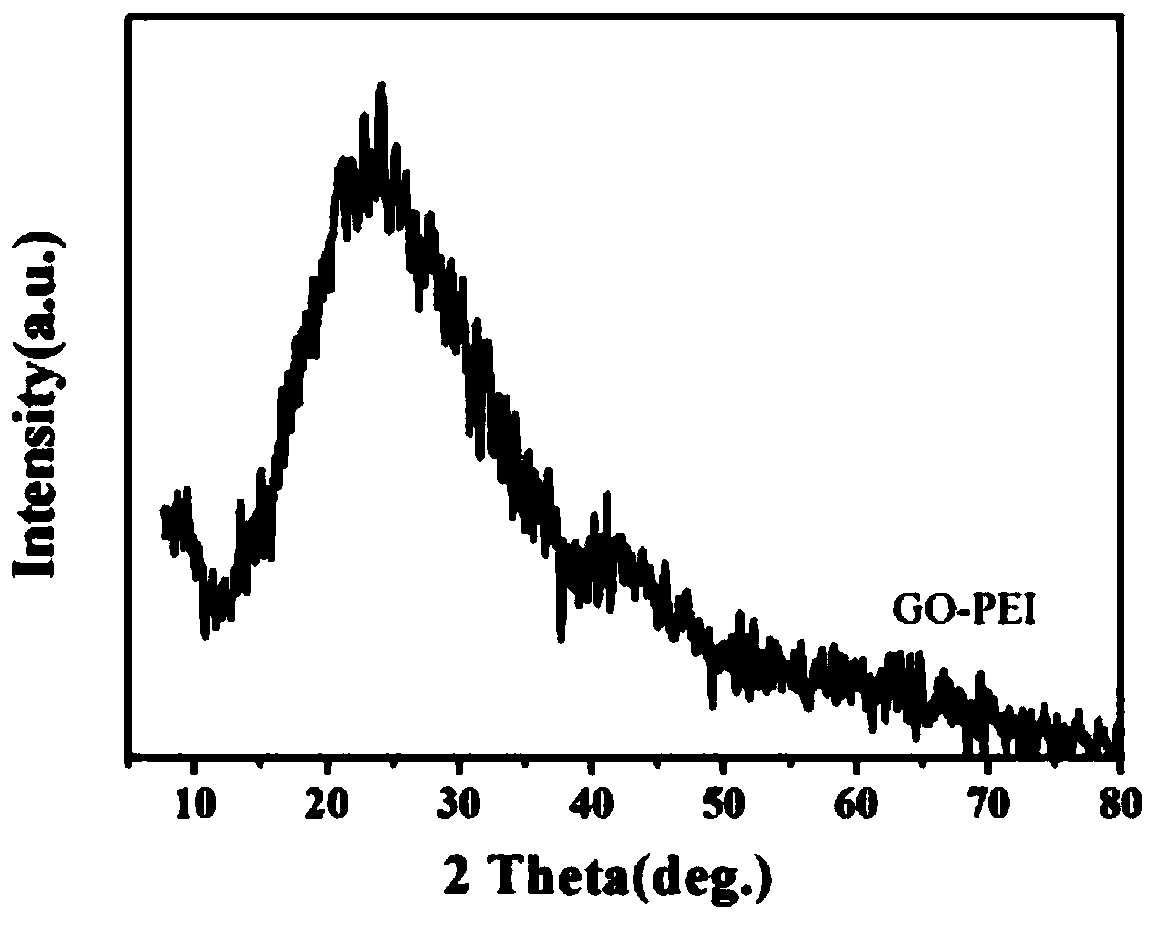

[0049] 1. Preparation of graphene oxide-polyethyleneimine composites

[0050] Polyethyleneimine (PEI), also known as polyethyleneimine, is a partially branched polymer water-soluble cationic polymer containing a large number of primary, secondary, and tertiary amines. Graphene oxide has strong organic compatibility and is soluble in various solvents, especially water. There are many groups on its surface, such as hydroxyl carboxyl groups and epoxy groups. The existence of these groups provides a large number of chemical reaction sites. point, which provides a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com