A Ni3S2/MnO composite material, a preparation method thereof and an application thereof in an aqueous alkaline battery

A composite material and electrodeposition technology, which is applied in the field of electrochemistry, can solve the problems of less positive electrode materials, low electrochemical performance, and complicated composite methods in aqueous alkaline batteries, and achieve good cycle stability, excellent rate performance, and increased potential sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Ni 3 S 2 The preparation method of / MnO composite material comprises steps as follows:

[0042] NiCl 2 , MnCl 2 The mixed solution with thiourea is the electrolyte, and the NiCl in the mixed solution 2 The concentration is 7.5mmolL -1 , MnCl 2 The concentration is 5mmol L -1 , the concentration of thiourea is 0.5mol L -1 , carbon paper was electrodeposited at a constant potential of -0.85V for 60min to electrodeposit active substances on the surface of the carbon paper. After washing and drying, a precursor product was obtained, and then calcined at 400°C for 2 hours in an Ar atmosphere to obtain Ni 3 S 2 / MnO composite (S1). The mass of active material on carbon paper is 4 mg cm- 2 .

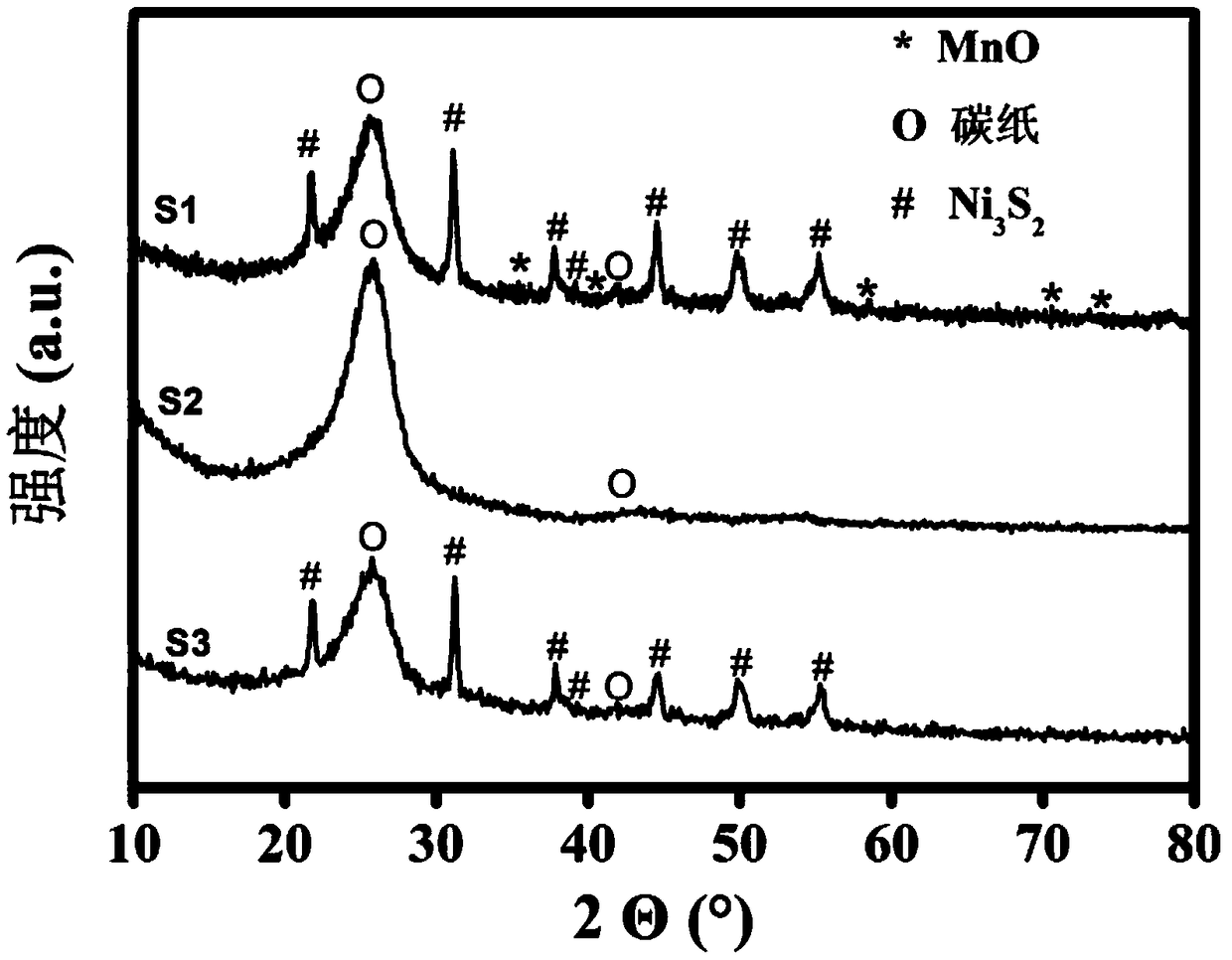

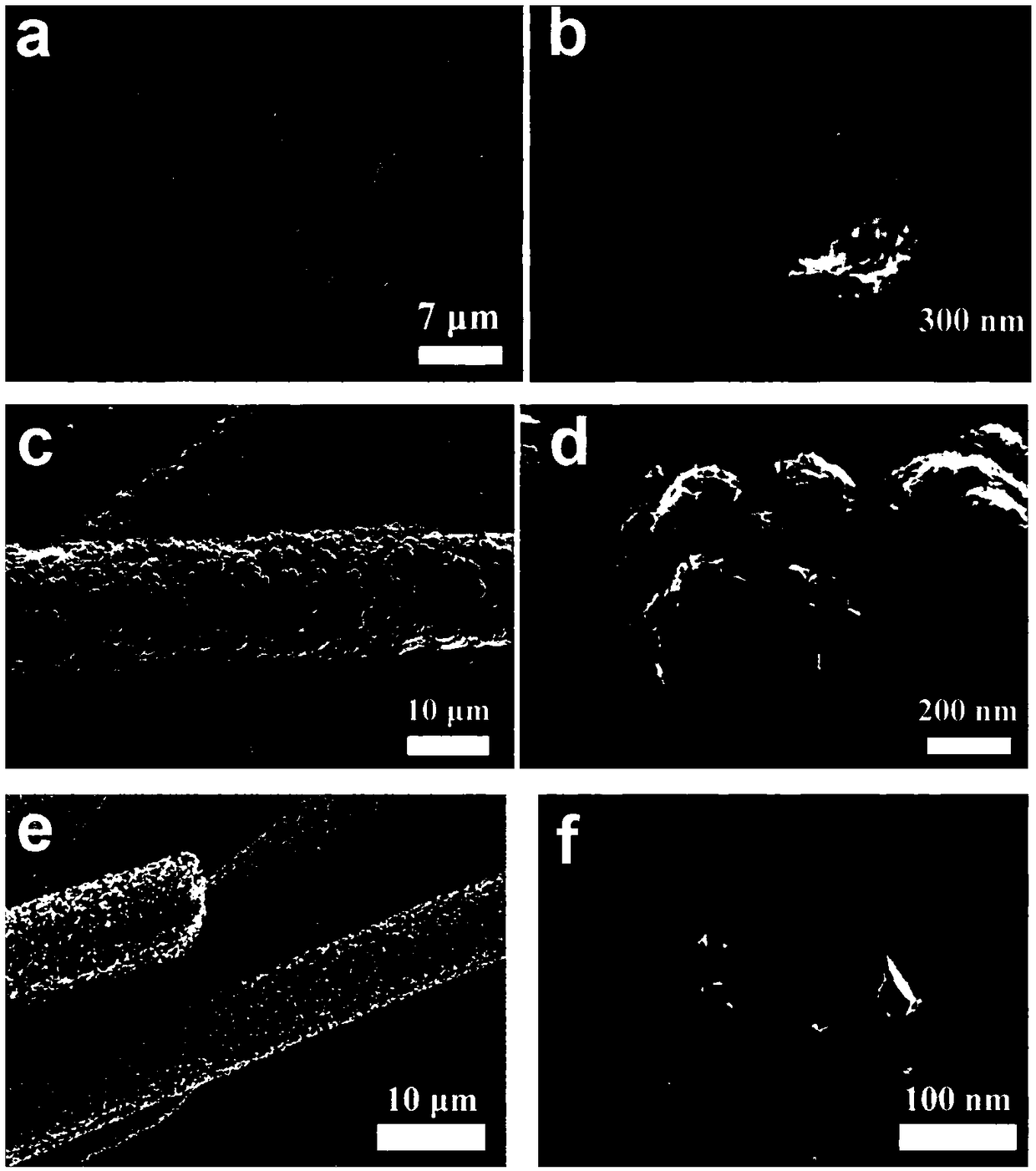

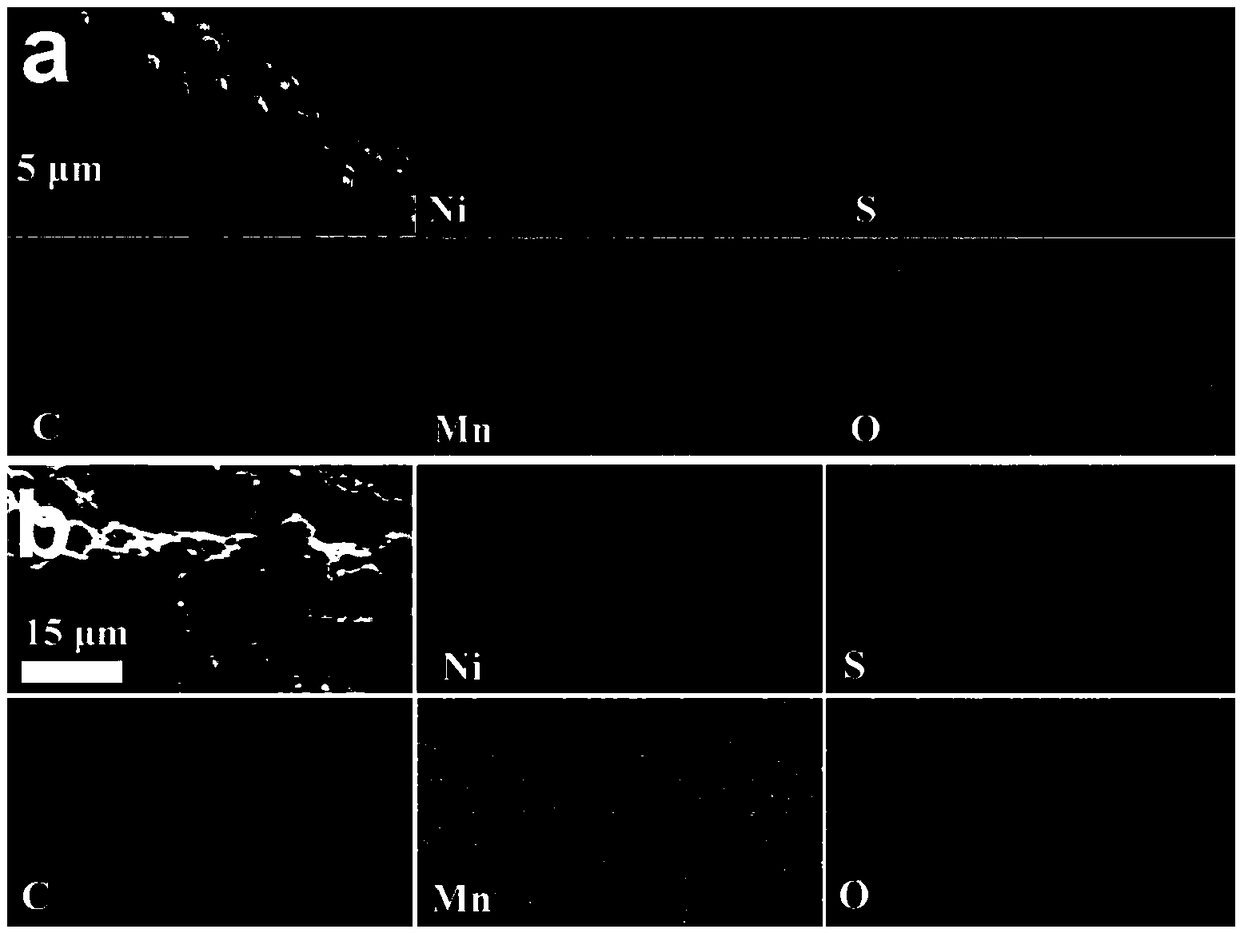

[0043] Ni produced 3 S 2 / MnO composite material (S1) XRD pattern and scanning electron microscope such as figure 1 , figure 2 shown by figure 2 It can be seen that the morphology of the material presents a granular combined cauliflower shape and is densely coated on the...

Embodiment 2

[0059] Ni as described in Example 1 3 S 2 / MnO composite preparation method, the difference is:

[0060] NiCl in mixed solution 2 The concentration is 2.5mmol L -1 , MnCl 2 The concentration is 7.5mmol L -1 , the concentration of thiourea is 0.5mol L -1 , the electrodeposition time is 30min, and the high-temperature calcination time is 1 hour to obtain Ni 3 S 2 / MnO composites with an active material mass of 1.5 mg cm on carbon paper -2 .

[0061] The morphology of the material presents the shape of granular combined cauliflower and is densely covered on the surface of carbon fiber. XRD test has carbon paper, Ni 3 S 2 And three different characteristic peaks of MnO, elemental mapping can be observed Mn element.

Embodiment 3

[0063] Ni as described in Example 1 3 S 2 / MnO composite preparation method, the difference is:

[0064] NiCl in mixed solution 2 The concentration is 15mmol L -1 , MnCl 2 The concentration is 10mmol L -1 , the concentration of thiourea is 1mol L -1 , the electrodeposition time is 120min, and the high-temperature calcination time is 3 hours to obtain Ni 3 S 2 / MnO composites with an active mass of 8 mg cm on carbon paper -2 .

[0065] The morphology of the material presents the shape of granular combined cauliflower and is densely covered on the surface of carbon fiber. XRD test has carbon paper, Ni 3 S 2 And three different characteristic peaks of MnO, elemental mapping can be observed Mn element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com