T-type conversion circuit and corresponding three-phase conversion circuit and conversion device

A technology for converting circuits and circuit modules, which is applied to output power conversion devices, AC power input conversion to DC power output, electrical components, etc., can solve problems such as power device noise pollution, large device stress, and complex design, and achieve output The filter parameter requirements are lowered, the power density of the product is improved, and the structure is simple and compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0101] In the second embodiment, the principle of realizing soft switching by the controllable switching device and the diode during the commutation process is similar to that of the first embodiment, and will not be described in detail here.

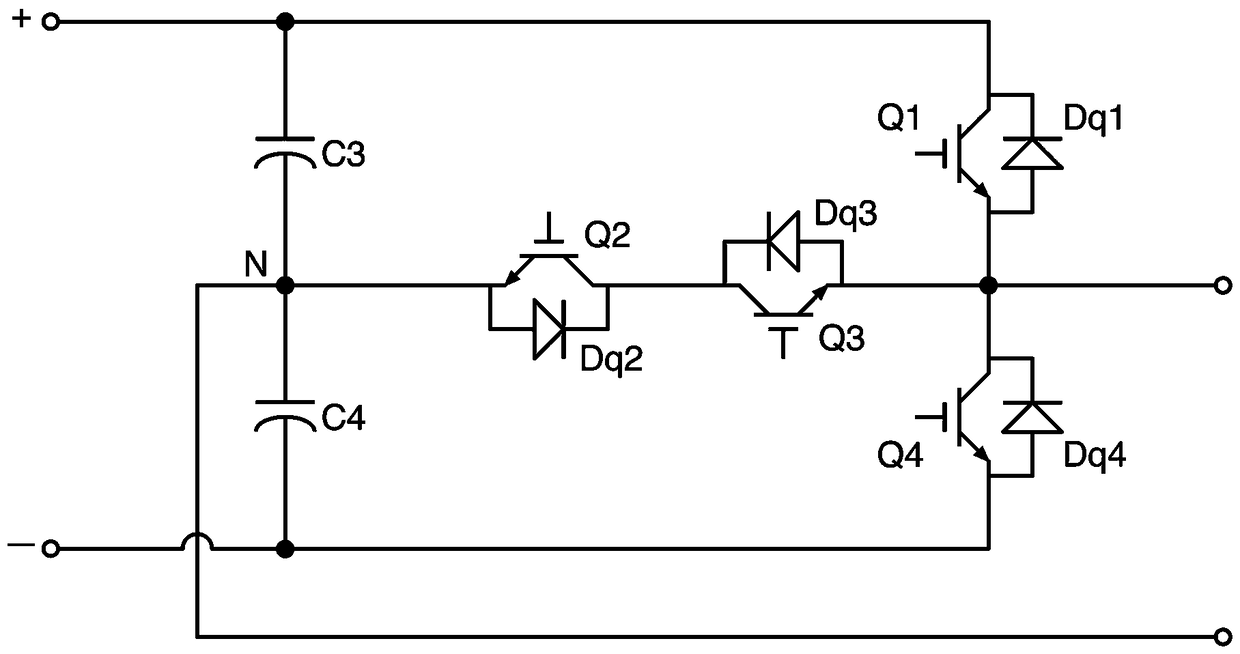

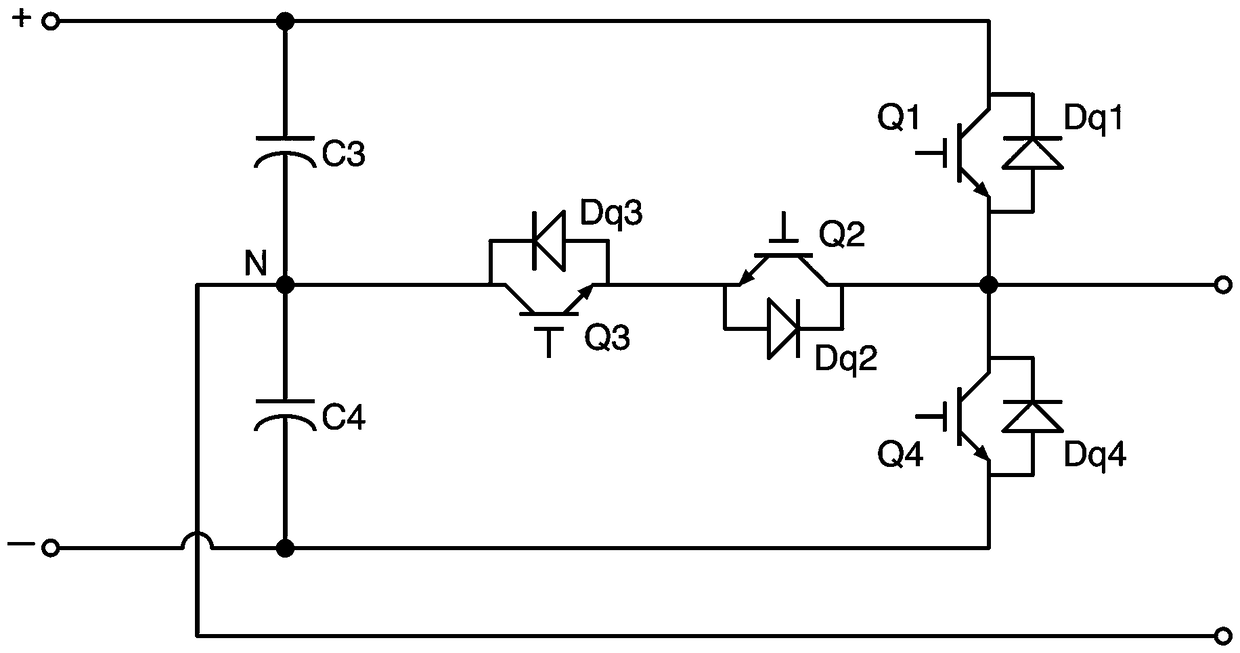

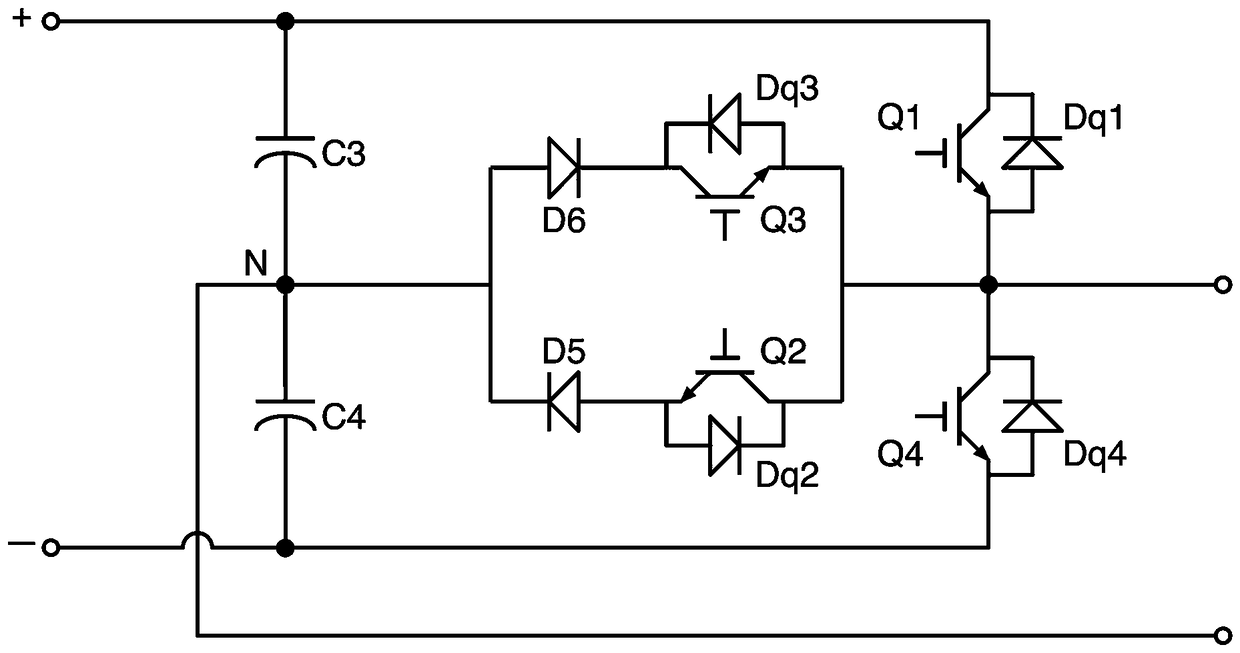

[0102] Image 6 A schematic circuit diagram of Embodiment 3 of the T-type conversion circuit in the present invention is shown. Such as Image 6 As shown, the third embodiment of the T-type conversion circuit includes two vertically arranged controllable switching devices, two horizontally arranged controllable switching devices, an inductor L, a first diode D1, and a second diode D2 , the third diode D3, the fourth diode D4, the fifth diode D5, the sixth diode D6, the first capacitor C1, the second capacitor C2, the third polarity capacitor C3 and the fourth polarity Capacitor C4.

[0103] The two vertically arranged controllable switching devices are respectively the first controllable switching device and the fourth controllable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com