Production method for stainless steel film plate

A production method, stainless steel technology, applied in the direction of chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of affecting the bonding performance of products, low bonding strength of products, and easy cracking, so as to broaden the scope of use, The effect of saving the length of the production line and improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

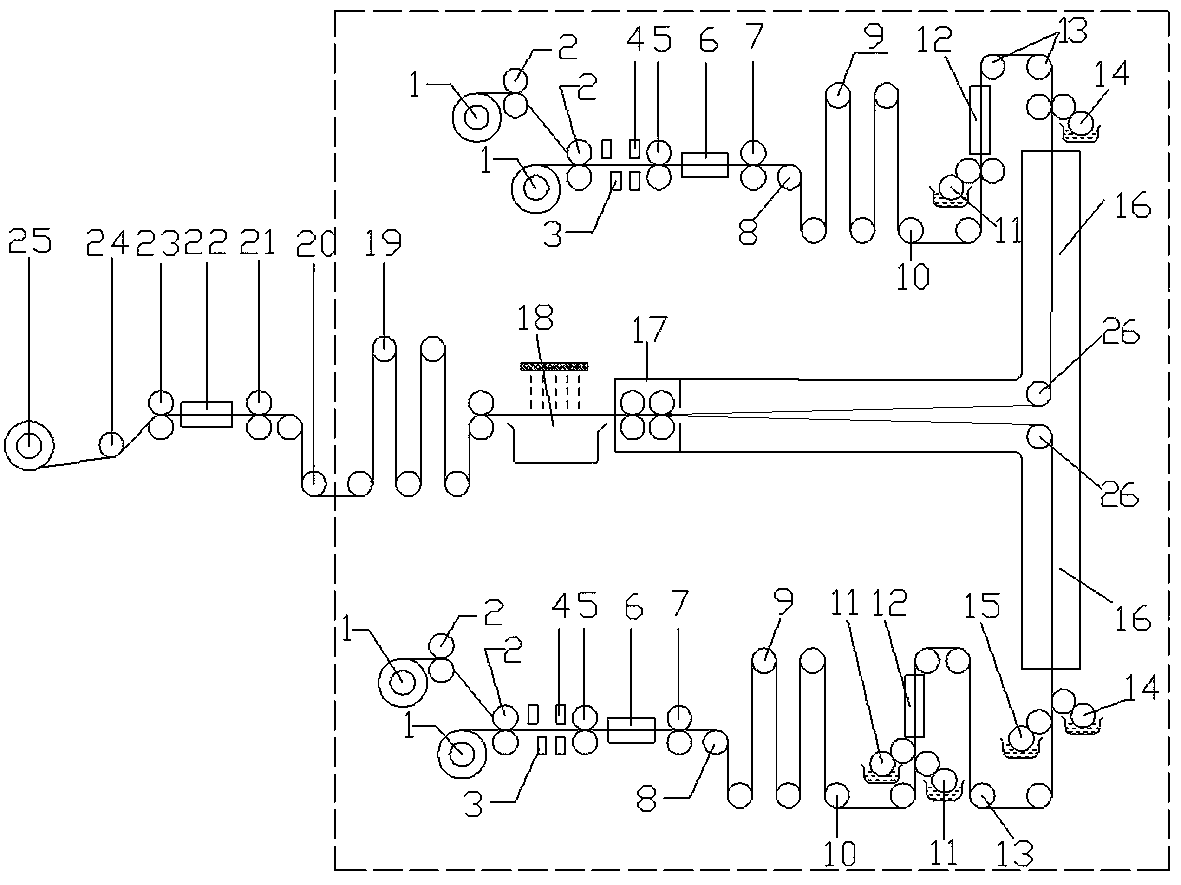

[0019] Referring to the figure, after the upper stainless steel coil and the lower aluminum coil are processed by the surface treatment unit 6, the chemical coating machine 11 coats a layer of chemical coating liquid on the composite surface of the upper stainless steel coil and the composite surface and exposed surface of the lower aluminum coil , After drying by the chemical coating drying oven 12; then the roller coater 14 coats a layer of liquid polymer resin on the surface to be compounded, and the back coater 15 coats the liquid polyurethane coating on the exposed surface of the lower aluminum coil and enters the T shape Drying furnace 16 performs polymer resin, paint solvent volatilization and preheating of raw material strips. The temperature in the furnace is 200°C; and the compounding unit 17 completes the compounding. The rolling pressure of the compounding roller of the compounding unit is 50t; after spraying The cooling unit 18 is forced to cool to normal temperatur...

Embodiment 2

[0022] Referring to the figure, after the upper layer of stainless steel coil and the lower layer of galvanized coil are processed by the surface treatment unit 6, the chemical coating machine 11 coats the surface of the stainless steel to be laminated and the surface of the galvanized coil each with a layer of chemical coating liquid. The chemical coating drying oven 12 is dried; then a layer of liquid polymer resin is coated on the upper stainless steel surface to be laminated and the galvanized coil surface to be laminated by the roller coater 14 respectively. The back coater 15 does not coat the protective coating and enters The T-shaped drying furnace 16 performs the volatilization of the polymer resin solvent and the preheating of the raw material strip, and the preheating temperature is 280℃; and the compounding unit 17 completes the compounding, and the rolling pressure of the compounding roller of the compounding unit is 80t; then it passes through the cooling unit 18 i...

Embodiment 3

[0025] Referring to the figure, after the upper layer of stainless steel coil and the lower layer of aluminum coil are processed by the surface treatment unit 6, the chemical coating machine 11 coats a layer of chemical coating liquid on both the stainless steel and aluminum coil surfaces to be composited. Drying in the drying oven 12; then the roller coater 14 coats a layer of liquid polymer resin on the upper stainless steel composite surface and the lower aluminum coil composite surface respectively. The back coater 15 does not apply environmentally friendly paint and enters the T-shaped drying Dry furnace 16 performs polymer resin solvent volatilization and preheating of raw material strips. The temperature in the furnace is 380°C; and the compounding unit 17 completes the compounding, and is forced to cool to room temperature through the cooling unit 18, and finally passes through the finishing unit 22 for finishing. Complete processing and complete finished product collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com