Circulating fluidized bed combustion ash based filling cemented material and preparation method of slurry of circulating fluidized bed combustion ash based filling cemented material

A technology of cementing material and filling slurry, which is applied in the field of mine filling cementing material and its preparation, can solve the problems of high cost, unfavorable application and development of tailings filling technology, high pollution, etc., achieve low bleeding rate and reduce filling cost , the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

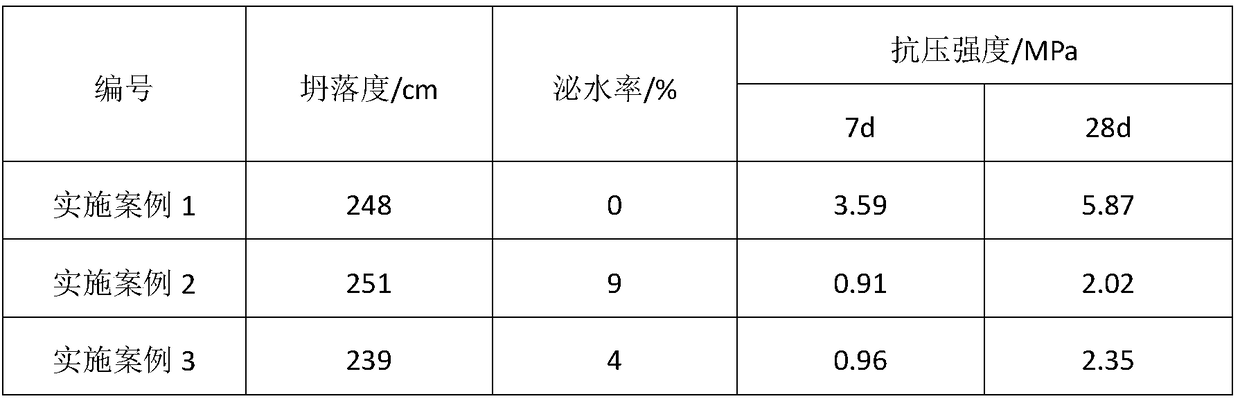

Embodiment 1

[0019] A sulfur-fixed ash-based filling cementing material, the raw materials and mass percentages are as follows:

[0020] 29% sulfur-fixed ash, 34% phosphorus tailings, 8.5% activator, 27.5% tap water.

[0021] Described exciter is the combination of water glass, unslaked lime and sodium sulfate, wherein water glass 2.8%, unslaked lime 5% (counted in cementitious material), sodium sulfate 0.7% (calculated in cemented material); Described percentage is all is the mass percentage.

[0022] The mortar weight ratio of the cementitious material to the fine aggregate is 1:1, and the solid mass concentration of the slurry is 70%; the stated percentages are all mass percentages.

[0023] The main chemical composition of the sulfur-fixing ash is SiO 2 、Al 2 o 3 , CaO and SO 3 , the specific surface area is not less than 350㎡ / kg.

[0024] The main chemical components of the phosphorus tailings are CaO, MgO and P 2 o 5 , the average particle size is 23.8μm, and the specific sur...

Embodiment 2

[0027] A sulfur-fixed ash-based filling cementing material, the raw materials and mass percentages are as follows:

[0028] 14% sulfur-fixed ash, 52% phosphorus tailings, 4.3% activator, 29.7% tap water.

[0029] Described exciter is the combination of water glass, unslaked lime and sodium sulfate, wherein water glass 1.3%, unslaked lime 2.6% (counted in cementitious material), sodium sulfate 0.4% (calculated in cemented material); Described percentage is all is the mass percentage.

[0030] The mortar weight ratio of the cementitious material to the fine aggregate is 1:3, and the solid mass concentration of the slurry is 70%; the stated percentages are all mass percentages.

[0031] The main chemical composition of the sulfur-fixing ash is SiO 2 、Al 2 o 3 , CaO and SO 3 , the specific surface area is not less than 350㎡ / kg.

[0032] The main chemical components of the phosphorus tailings are CaO, MgO and P 2 o 5 , the average particle size is 23.8μm, and the specific s...

Embodiment 3

[0036] A sulfur-fixed ash-based filling cementing material, the raw materials and mass percentages are as follows:

[0037] 12% sulfur-fixing ash, 58% phosphorus tailings, 3.6% activator, 26.4% tap water.

[0038] Described exciter is the combination of water glass, unslaked lime and sodium sulfate, wherein water glass 1.1%, unslaked lime 2.2% (counted in cementitious material), sodium sulfate 0.3% (calculated in cemented material); Described percentage is all is the mass percentage.

[0039] The mortar weight ratio of the cementitious material to the fine aggregate is 1:4, and the solid mass concentration of the slurry is 73%; the stated percentages are all mass percentages.

[0040] The main chemical composition of the sulfur-fixing ash is SiO 2 、Al 2 o 3 , CaO and SO 3 , the specific surface area is not less than 350㎡ / kg.

[0041] The main chemical components of the phosphorus tailings are CaO, MgO and P 2 o 5 , the average particle size is 23.8μm, and the specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com