A kind of chlorinated rubber synergistically modified by nano-additive and sodium polyoxyethylene sulfonate, its preparation method and application

A nano-additive, chlorinated rubber technology, applied in rubber derivative coatings, coatings, etc., can solve problems such as reducing production costs, and achieve the effects of good chlorination uniformity, uniform powder particles, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

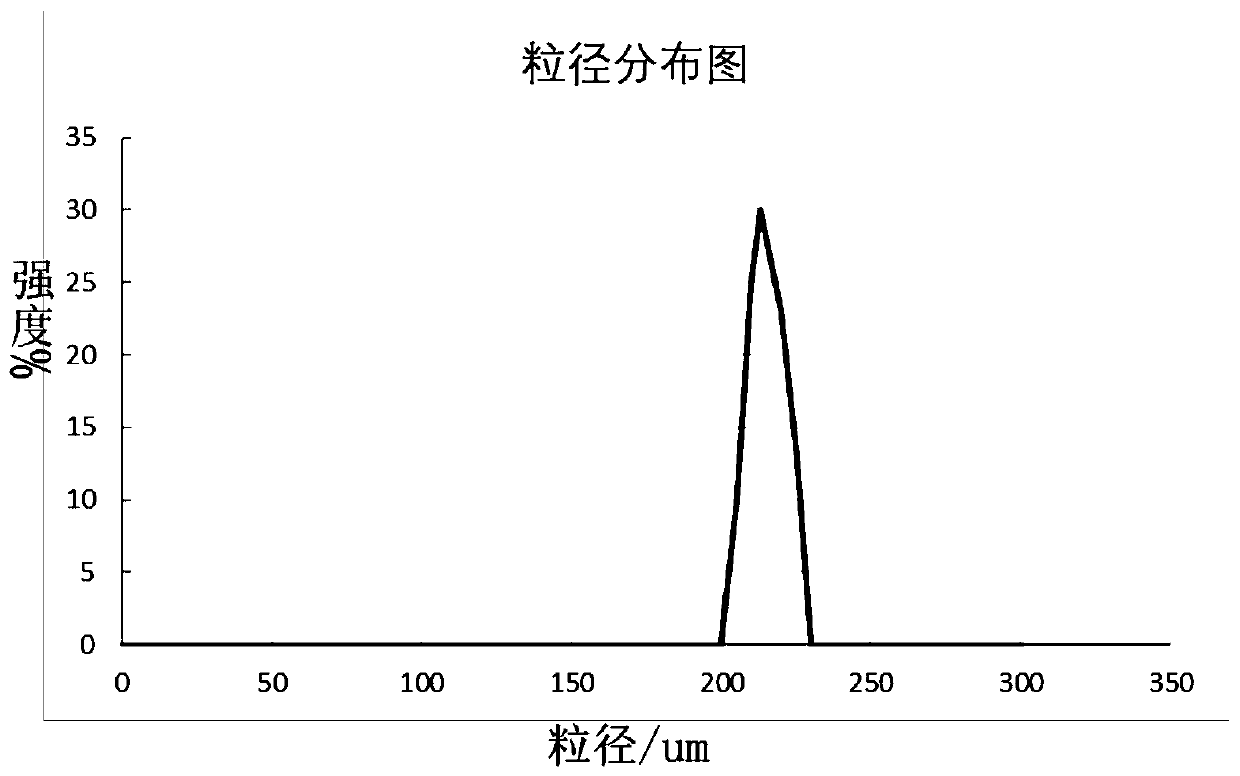

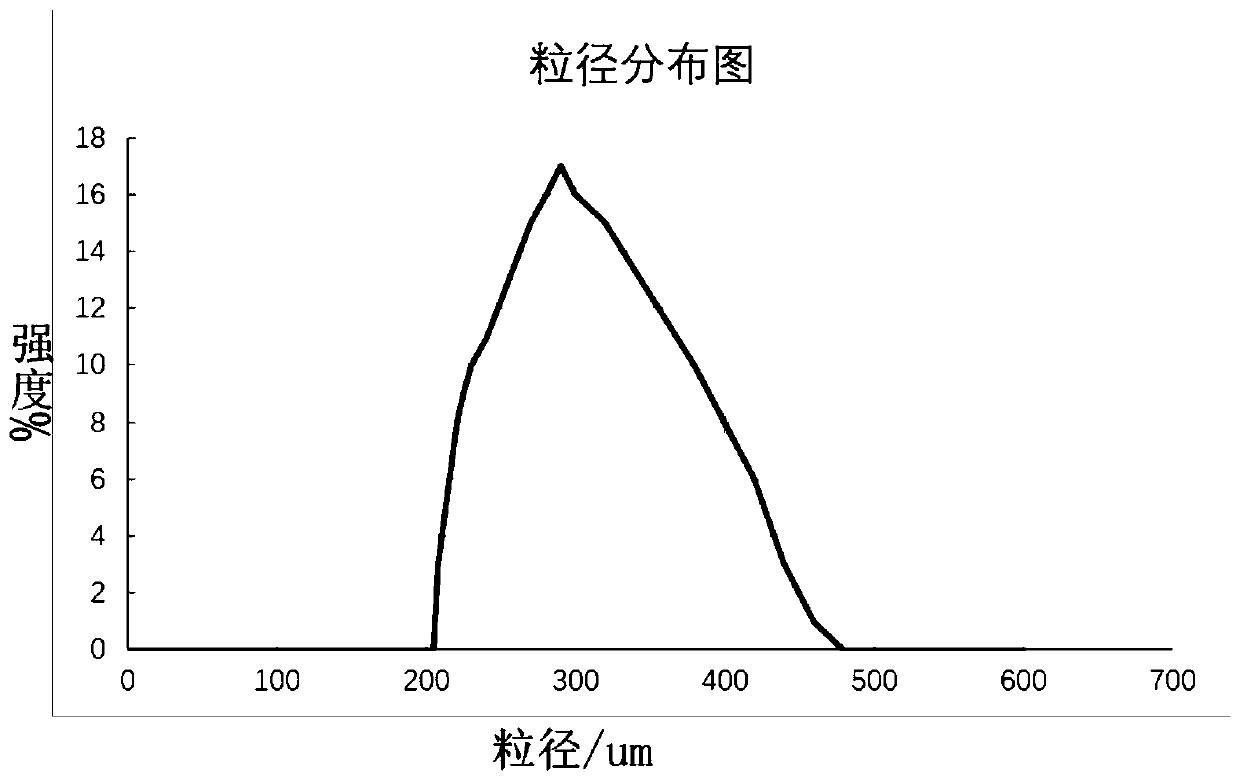

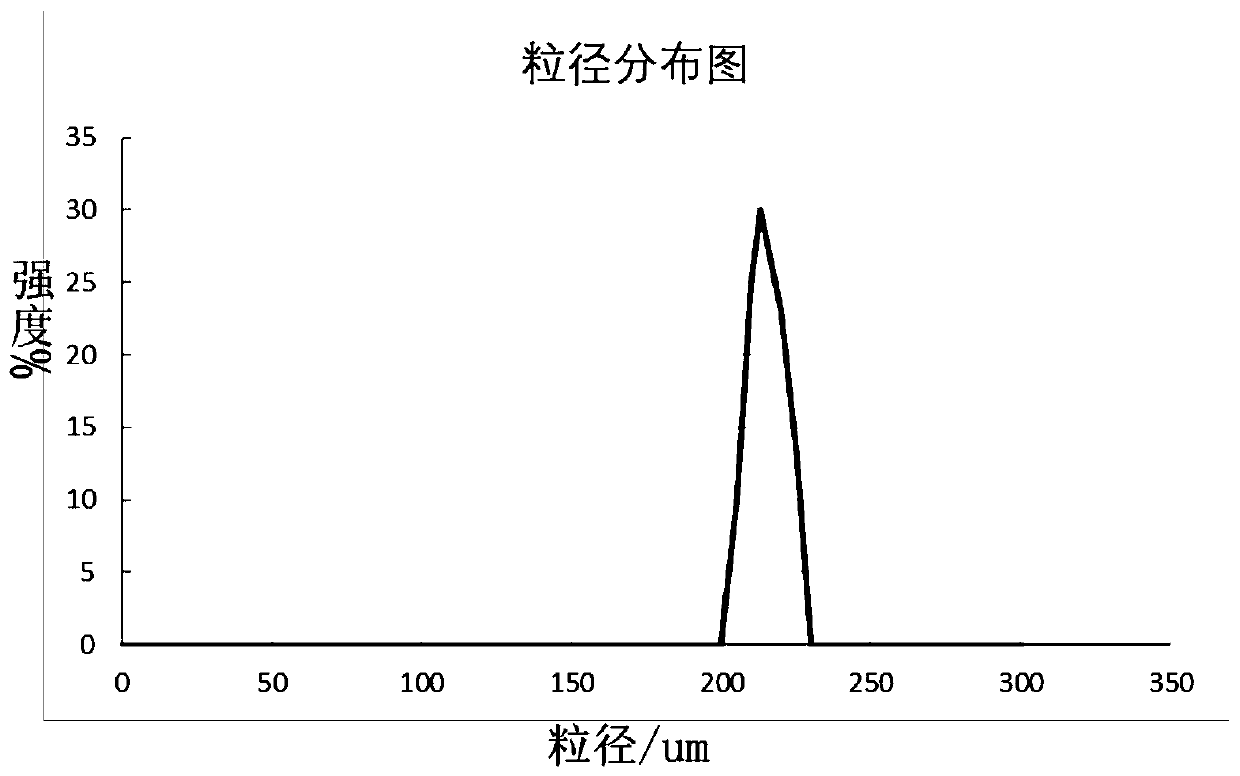

Image

Examples

Embodiment 1

[0053] The preparation of embodiment 1 chlorinated rubber 1 (sodium polyoxyethylene sulfonate and nano tungsten disulfide synergistically)

[0054] Dissolve 0.6 parts of anionic surfactant dodecyl phosphate and 1 part of nonionic surfactant triethanolamine in 1000 parts of deionized water to prepare a compound surfactant solution; inject the solution into a three-necked bottle, and then add to the reaction Add 100 parts of natural latex, 1 part of emulsifier polyoxyethylene sodium sulfonate, 0.1 part of dispersant alkyltrimethylammonium chloride, and 0.3 part of reaction catalyst lauryl peroxide, and stir well to form a stable aqueous phase suspension liquid. Introduce nitrogen into the reaction system to discharge the air, heat the three-necked bottle to slowly heat up the solution, slowly introduce chlorine gas while stirring, add 0.5 parts of nano-tungsten disulfide when the temperature rises to 50°C, and maintain 50°C until the amount of chlorine gas introduced Reach 40%;...

Embodiment 2

[0056] Preparation of embodiment 2 chlorinated rubber 2 (sodium polyoxyethylene sulfonate and nano tungsten disulfide are all absent)

[0057] Dissolve 0.6 parts of anionic surfactant dodecyl phosphate and 1 part of nonionic surfactant triethanolamine in 1000 parts of deionized water to prepare a compound surfactant solution; inject the solution into a three-necked bottle, and then add to the reaction Add 100 parts of natural latex, 1 part of diethanolamine lauryl sulfate, 0.1 part of dispersant alkyltrimethylammonium chloride, and 0.3 parts of reaction catalyst lauryl peroxide into the system, and stir well to form a stable water phase suspension. Introduce nitrogen into the reaction system to expel the air, heat the three-necked bottle to slowly heat up the solution, slowly introduce chlorine gas while stirring, add 0.5 parts of nano-molybdenum disulfide when the temperature rises to 50°C, and maintain 50°C until the amount of chlorine gas introduced Reach 40%; continue to ...

Embodiment 3

[0059] Preparation of embodiment 3 chlorinated rubber 3 (only containing nanometer tungsten disulfide)

[0060] Dissolve 0.6 parts of anionic surfactant dodecyl phosphate and 1 part of nonionic surfactant triethanolamine in 1000 parts of deionized water to prepare a compound surfactant solution; inject the solution into a three-necked bottle, and then add to the reaction Add 100 parts of natural latex, 1 part of diethanolamine lauryl sulfate, 0.1 part of dispersant alkyltrimethylammonium chloride, and 0.3 parts of reaction catalyst lauryl peroxide into the system, and stir well to form a stable water phase suspension. Introduce nitrogen into the reaction system to discharge the air, heat the three-necked bottle to slowly heat up the solution, slowly introduce chlorine gas while stirring, add 0.5 parts of nano-tungsten disulfide when the temperature rises to 50°C, and maintain 50°C until the amount of chlorine gas introduced Reach 40%; continue to heat up, when the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com