High-damping blended rubber with effective damping temperature range greater than 65 DEG C and preparation method thereof

A technology of blended rubber and high damping, which is applied in the field of preparation of high damping blended rubber, can solve the problems of complex steps, difficult operation and increased cost of the in-situ blending method, and achieve large-scale industrial production and reduce Effects of environmental pollution and improvement of damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

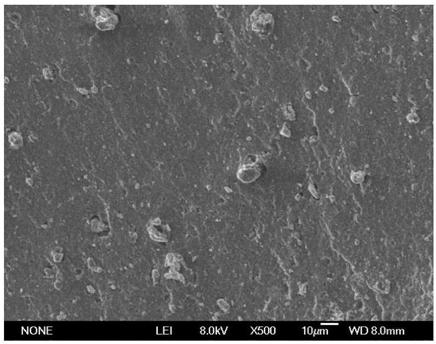

Embodiment 1

[0033] The ionomer MFHVBR-Mt was prepared by reacting 100 g of MFHVBR with a maleic anhydride content of 3.25% and 5 g of sodium hydroxide. Using an internal mixer, the initial temperature is set to 100°C, the rotor speed is 50r / min, 80gMFHVBR-Mt and 20gEVM are added to it and masticated for 2min, and small materials (zinc oxide, stearic acid, magnesium oxide, anti-aging agent, Accelerator), carbon black and operating oil, degreasing, then add accelerator and accelerator on the open mill, thin pass 6 times to get the MFHVBR-Mt / EVM compound rubber, and then vulcanize the sample preparation.

Embodiment 2

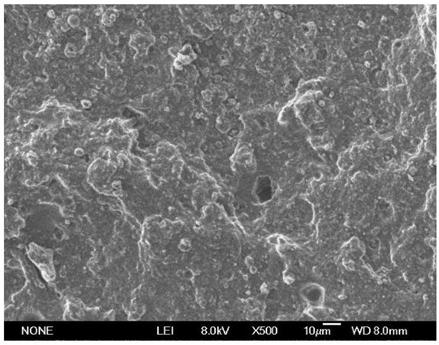

[0042] Example 2: 100 g of MFHVBR with a maleic anhydride content of 3.25% was reacted with 3 g of sodium hydroxide to prepare ionomer MFHVBR-Mt. According to the operating steps of Example 1, 70g MFHVBR-Mt and 30g EVM were blended to prepare MFHVBR-Mt / EVM compound rubber.

Embodiment 3

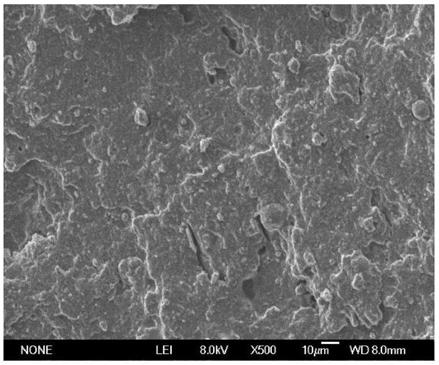

[0048] Example 3: 100 g of MFHVBR with a maleic anhydride content of 3.25% was reacted with 6 g of sodium hydroxide to prepare ionomer MFHVBR-Mt. According to the operating steps of Example 1, 80g MFHVBR-Mt and 20g EVM were blended to prepare MFHVBR-Mt / EVM compound rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com